Key Features of PU Screen Mesh for High-Precision Operations

Superior Wear Resistance in Harsh Environments

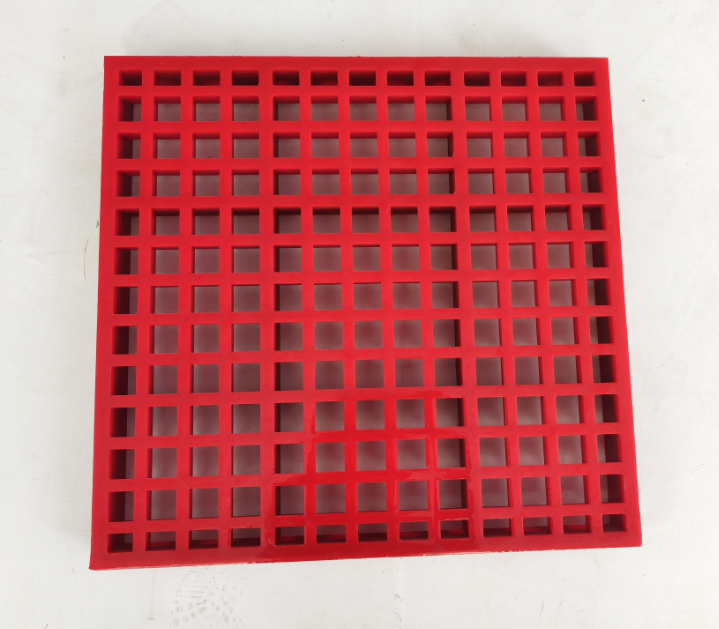

PU screen mesh has excellent abrasion resistance, and the performance is similar with that of rubber.PU mesh plate is used in mining, metallurgy, coal, building materials,water conservancy,construction industry,etc. Research has demonstrated that PU meshes have a lifespan of up to five times longer than traditional materials under these rigorous conditions. The mesh is extremely strong and has high abrasion resistance, thanks to the proprietary combination of polyurethane material that it’s constructed from, and this means that the mesh can handle a high-quality digital print with perfect precision, time and time again. This durability translates to lower downtime and fewer replacement costs for businesses.

Chemical Stability for Corrosion-Prone Applications

Polyurethane Screen Polyurethane screen mesh polyurethane screen, polyurethane screen meshpolyurethane screen panels, polyurethane if you want long wear ltds polyurethane panels are made with high quality materials and assuring optimum performance and us for the With the GET flexy system, our premium D6 push-section now offers maximum protection. This characteristic means less-replacement and less downtime. Studies indicate that PU meshes exhibit lower degradation when subject to a series of acids and bases, leading to a longer standing. Those qualities make them crucial pieces in tough environments like chemical plants and sewage treatment facilities — where keeping the material from breaking down is important to keeping thing running smoothly.

Anti-Blinding Properties for Uninterrupted Screening

To prevent screen blind, the anti-blinding PU screen mesh is necessary or pneumatic tyres can be added to be mobile to provide ease of movement and repositioning to optimize efficiency. Integrated studies have demonstrated that the PU screens and polyurethane suitability Increased Throughput up to 20+% (see specific apps ); hence have been tested and proven valuable in sustaining the performance. PU mesh maintains its performance principle of delivering unobstructed processing while reducing clogging and can therefore make a major contribution to consistent screening, which is a basic requirement for precise and reliable production processes, especially in industries with stringent quality standards.

Industrial Applications of Polyurethane Screening Solutions

Mining and Mineral Processing Efficiency

Polyurethane (PU) screen mesh can be used in the mining, quarrying, and so on.Material:PU or Rubber. PU screen for mining can be employed in tough mining environments, to the level of third or fourth screening stage and are quite resistant to abrasions. Field tests have shown a higher efficiency of valuable mineral recovery from PU screen meshes than from conventional screens. This results in increased operational productivity, minimized equipment downtime and lower overall operational costs in mining applications. Such perks of PU screen let it be very useful in mining industry.

Coal Washeries and Aggregate Classification

In coal washeries and in aggregate classification polyurethane Trommel screens, as they are know, they genuinely succeed when shown the task of effectively dewatering, washing and classification. The flexible design and high quality make for smooth operation, and less jamming. PU screen solutions have showed significant results in studies, including the decline of net influx and clogging from run-off. In addition, these enhancements contribute to increased productivity and reduced costs / cost of ownership for the processing industry – customers leverage thin wire PU screens for high wear applications, in coal and aggregates.

Dewatering in Wet Screening Operations

Polyurethane screens perform very well in wet and dry applications due to their high open area and flexible surface Harmoni cut swe can tery to water a d water and slurry dynamics to imp crops and duct the material while resisting abrasion. Their higher quality enables to decrease the moisture content notably in the dewatering process as it can be observed through the laboratory experiments. This is important in applications like moisture control, where maintaining the right level (or even changing if necessary) can make a hole in one’s efficiency and output. Sustaining high performance in wet environments, PU screens promote operational reliability and are ideal for wet processing applications.

PU vs Traditional Materials: Rubber and Steel Compared

Noise Reduction Advantages Over Steel Mesh

PU screen mesh has excellent sound-absorption can pass rarely sound, which is the ideal choice in the situation of production safety. PU screens, in fact, can reduce noise levels by more than 10 dB when compared to steel screens. This decrease in noise pollution also results in a more favourable workplace environment through reducing workers' audio fatigue. It is an added factor, particularly in heavy-duty applications, where the sound of machinery never stops, and productivity and the well-being of workers benefit.

Extended Lifespan Compared to Woven Wire Screens

PU screens are much more wear resistant than woven vibrating screens, thus, they have a longer service life and replacement. PU meshes, according to industry reports last at least twice as long as wire screens under the same conditions and are less expensive when it comes to cost execution in any demanding application. The durability provides businesses with long-term, trouble-free use, as opposed to the recurring problems and costs incurred with the purchase of worn screens. Resistant to tearing and sticking; PU screening has antiwear effect that is able to last at least 10 times that of common wire cloth mesh due to the use of highly abrasion resistant polyurethane to bring high efficiency and long service life.

Flexibility vs Rigidity in Material Separation

And due to the naturality of PU, which is more flexible than rigid material, so it is better for applying to different screening process than the rigid one. This versatility allows the user to follow a multitude of material size, making it a very flexible screening system without the need for additional conveyors. PU is flexible and permits a wider range of motion, which makes it more effective for serving various industrial purposes. This material property greatly improves the process of separation which allows for high-performance screening and a good overall operation, especially for industries dealing with difficult raw material movements.

Innovations in Polyester Filter Screen Technology

Modular Design for Custom Configurations

Polyester filter screen modular design is changing the industry in that it can be customized at an unprecedented level. This adaptability allows for specific operations requirements and adds to overall utility. Procedures such as this can be adapted to existing systems, and such adaptability is a great advantage in manufacturing operations. The modular concept offers flexibility and simplifies replacement and upgrading – a good fit for the changing demands of production today. Or opening up for configurations we can make changes to that they want to exploit in the next evolution of the business.Use caseBy providing the ability to configure by need businesses can create a filter system optimized for their use case,Making their business run more efficient and cost-effective.

Thermoplastic vs Thermoset PU Performance

Performance differences between thermoplastic and thermoset polyurethane (PU) materials are important in applications. Thermoplastic PU is also widely known for its superior impact resistance, and thus has become the leading choice for applications that undergo high physical abuse. On the other hand, thermoset PU has good chemical and thermal resistance and can be used in applications requiring resistance to chemical conditions and high temperature. Comparative analysis allows businesses to make better decisions—choosing materials that closely align with their requirements and limitations, and improving operational results as a result.

RFID-Enabled Smart Screening Systems

For logistical processes, RFID technology embedded in screen mesh systems is a game-changer in terms of operations. With the capability to monitor and manage material flow in real-time, RFID-enabled solutions improve the accuracy and dependability of screening operations. These smart systems have been demonstrated to reduce downtime, by predicting when maintenance was required from sophisticated tracking of wear and tear. This proactive approach ensures that the unexpected don't happen, the best use of resources and prolonged equipment life making it an indispensable addition to today’s screening technology.

Optimizing Screen Mesh Performance and Longevity

Proper Tensioning Techniques for Vibration Efficiency

Using a right tensioning method is very important when applying a wire mesh to ensure it works in numerous conditions. This helps keep the tensioning effective so as the screen mesh is not slack and lose and to inefficient material separation. This not only achieves an optimal distribution of the material thanks to the crossflow sieve, also ensures improved screening accuracy and increases the service life of the screen fabrics through a reduction of abrasion. Applying best tensioning practices; Tensioning with calibrated tension meters and according to tensioning procedures, will eliminate undue tension on the mesh and maintain consistent tension levels, resulting in prolonged mesh life. Optimum tension allows the screen to be installed and removed during operation without the need for any additional clearance.

Cleaning Protocols for Different Material Types

Material-specific cleaning procedures are essential for proper maintenance of screen mesh systems. Particular materials, e.g. fine particles and sticky materials, tend to blind the openings in the mesh to differing extents with the subsequent effect on the performance of the screener. By using material type specific industrial cleaning guidelines this problem can be reduced. For example, clear-activating high-pressure water jets or abrasive cleaning techniques can be used to keep meshes free from blockages in processes involving tacky or fine products. By implementing investment-grade cleaning solutions, businesses can maintain performance level and limit performance loss over time, maximizing the life of their screen mesh systems.

When to Replace vs Repair Screen Components

Whether to repair or replace screen parts is a critical decision to ensure productivity levels while minimizing expenses. This important decision process is informed by regular monitoring of screen component wear levels. If only a little bit broken (not really affecting use), repairing is more economic. But if wear and tear has done in the crucial components, replacing them is more feasible than enduring downtime. Finding the right mix of repair versus replacement can help add life to a company’s screening operations as well as potentially saving money and eliminating downtime.