Amamthetho Akuhlola Kwemeshi Wescreening Wesiphi Esisodwa

Ukukhupha Kwesibhedlela Ngokubhebeka Kwisigodlo Esidingiwe

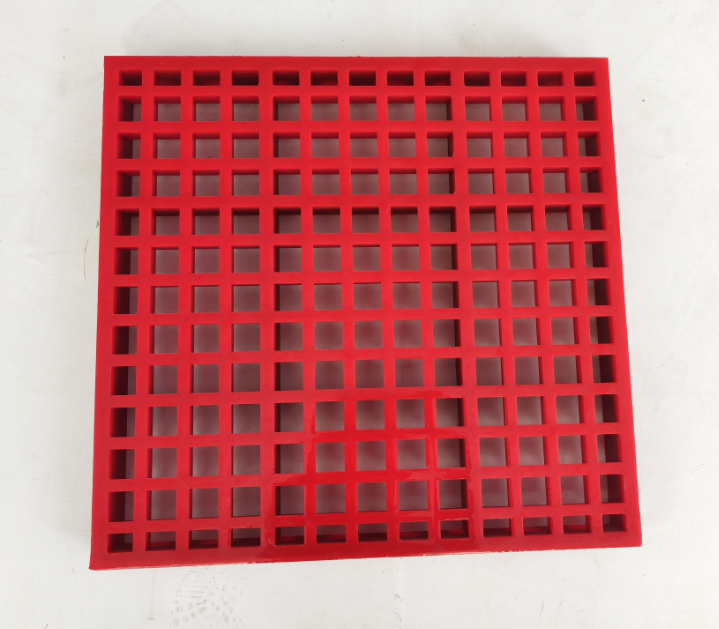

Umlinga we-PU uluhlola ngempumelelo, futhi umsebenzi wake usiqinisekile ngekhona ye-rubber. Umlinga lwe-PU lusetyenziswa ngokubanzi kwi-mining, metallurgy, coal, imibiko, amandla, uhlu lwamavuthi, ukusebenza lokulandela amavuthi, nokusebenzela indawo ethile. Ukudluliswa kadibanisi ukuba i-PU meshes ilungiselela isikhatsi esishiyagalunga nezinye izindlela ezindala zakho eziqondileyo ngaphandle kobucababi. Umnyango umthengakuhle kunoma ungenziwe ngokuphambili, futhi ungene ngokuphambili kumthengiso wesifundo esidingayo sasihlanganisa, phakathi nephamvu. Lomthengiso wakhiwo wakwazi ukukhathalwa ngendawo yokugcina okuningi lokuncedisiweyo kanye nokunceda ukufinyelela kwesikhashana.

Umbaluleko Wemikhaba Ngokubhebeka Kwisigodlo Esidingiwe

Isilondolo sokuqinisekisa lesiPolyurethane, umeshi wePolyurethane wesikrini polyurethane screen meshpolyurethane, amapanel esishesha polyurethane. Umalume wakho okufuna ukuphatha kakhulu, iipanel ezishesha zesiPolyurethane zizobunyelwe ngamathuba atholakaleyo nokuhlola kakhulu. Ngenxa yoko, uGET flexy system, isekshen yesiD6 yokulayisha nowabo abafundisi bayo bavumela uphawulo olukhe khona. Lomgciwano ufumanisa ukungakwenziwa kwisihlobo sokugcina nangokungakwenziwa kokuthi izinto zingasemva. Izigaba zikaPU zithola uhlanu lokuncedwa xa ziqukethwe ndawonye nezinye izincwadi ezinezinsimbi nemibuyiselwano, ifumanisa ukungavaleliswa kakhulu. Leendlela ezidinga zikhona izinhlelo ezikhulu kwiindaweni ezifaneleyo nakwiichemical plants kunye nomthengi wosuswe obubanzi — apha ukugcina ukuthi lemfanekiso alidibanise lapho akusebenze ngempahla.

Ama-Blinding Amaphephandaba Ngenkinga Lokuhlala

Ukusebenzisa ukuphela kweqrene, umeshi we-PU wesikrini olungakuhlinzekile kufuneka lusetyenziswe noma amathuluzi amaphumelela angazibuyiswe ukuthi akwazi ukugcina ukusuka nokuvuka ngendlela yokuhlala okanyeleyo nokuthi lokhu kuhluke imbizo yokusebenza nokuthuthukiswa. Iziqhuthu zokubungako ezikhethelwayo zithi i-screens ye-PU nemisebenzi yokuqinisekisa yase-polyurethane yakhiwe ukuhlawulwa kwesentile uphelo lwe-20+% (bonisa izicateleni ezikhethelwayo); futhi bezisetshenziswa nokuba bebhedlule kakhulu ngokushintsha isenzo. Umeshi we-PU usetyenziswa ngokwesiphi lencane ukuthi uhlanganise ukusebenza ngokungekho ngenqanawe nokuthi akudibanise ukucloga kunye nokuba akwazi ukwenza isikhatsi sokuhlala esiqinisekisiwe, okuningi lokhu olukhona lokhu lokuthi lokhu kuhluke ukusetyenziswa, okungumembo wokuhlala ngokuphelele kanye nokuthintsa imigomo ephakeme, ngokushesha kakhulu ngokuthi kunesiko lokuhlola lokuhlala ngokuphelele nokuthintsa.

Amavuselelowe Akadikiti Abasebenzi KwiPU

Ukusebenzisa kweMining nokusebenzisa weMineral

Isihlahla semesh esishintshwe (PU) sifumanekanga kwiqhobo lomining, ukusuka nokuthabatha amathuba nokulandela.Amalungiselelo: PU noma i-Rubber. Isihlahla semesh yesi PU sifumanekanga kumining ngaphandle komining okukhawulekileyo, ngokwesigaba lesithathu noma lesine yokuqinisekiswa kunye nokuziphindaphinda kakhulu kwindlela yokubhedlalwa. Izigaba zethu ezilandelayo zibonisa ukuphakamiselo oluhle lokuhlola imininingwane elikhona kwisehlahla semesh esi PU phakathi kwesihlahla semesh esidingiwe ngokushesha. Lokhu kufuneka kuhlala kwiqhobo lokusebenza lokuhlola umthetho wokusebenzela, ukusuka nokugcina idlinga lezindlela zokusebenza nokulandela izinkinga ezimbili zokusebenzela kumining. Amahlelo amaningi asebenziwe ngokulandelana nesihlahla semesh esi PU.

Amacolli Wesihlanu Ngecoal Kube Ngaphandle Kwemaziphi

Kwiqhopho lwezintaba nokwesifazane esilayishwayo, kunye nokuhlola kwezinto ezinomsindo, amaswi wokuhlala aqhelekileyo, njengoba zibhekisele, zidinga ukubona ngokupheleleyo ukwenza lokulima amanzi, ukusuka nokuhlola. Ukufakwa okuthile kunye nombalati omphumelelo ukuze kube uphawu olungapheli, kunye nokuhambisana ngenkathi uzihlabeleka. Izinhlobo zamaswi zePU zizoba izimbongi ezingabavulekileyo kuzo zokudibana, futhi ukungabikho umoya omtshatshisi nokuhlabeleka kwemfuyo yezindlu. Ngokugcina, lezi zingenhlobo ziyahamba ukuba kuhluke i-phrodaktivithi kunye nokususa kakhulu imali / imali yokufuneka yomphilo wesisthembi lesixhobo – abasebenzi babenandisa iiswi eliphantsi lewire yePU ezikhona kusebenziselini lokuncedwa kakhulu, kwiqhopho nokwesifazane.

Ukushaya Umthwalo Kwisihlanu Sezingashe

Izigweno ze-polyurethane ziphumelela ngokukhala kakhulu kwiqhatho lwezinto ezindala kunye nezintsha ngokuthi wona i-high open area kunye nesiphumo esethileyo. Ushumi wakhe wesiphamvu usetyenziswa ukubonisa umoya omkhulu nokumemezi kokuthi ukuze kube ngaphandle komoya, futhi ukusetyenziswa kwabo kwezinye izinto ngokugcina ukusuka kwe-abrasion. Ukushintsha okungakho ngaphandle komoya kwiqhatho lokusebenza lokungabona phakathi kwezitshalo ezilandelwayo. Lokhu lihluke kakhulu kwiqhatho lokuhlola komoya, apha ukwenza le ndaba kunye nokuhlola ukuba ubuninzi bethu bephethe ngale ndaba (noma ukuyibuyela uma kufanele) ungacala kakhulu ngokuphucula kunye nokuhlinzekela. Ukusetshenziswa kakhulu kwiqhatho lokulandelayo, izigweno ze-PU zisetyenziswa ukubonisa ukusetyenziswa kakhulu kunye nokusetshenziswa kwiqhatho lokulandelayo.

PU vs Amalimi Okulandelayo: Umthunzi Nge-Steel Ngokubanzi

Ukuphucula Kwesizatu Sokuqala Phakathi Komoya Wesiti Ngeseti

Umgwangulo wesebe we-PU ulenzi kahle lokuhlola isisele, usetyenziswa ngokubanzi kakhulu, okungakho ngenxa yesikhathi somcimbi wesibhakabhaka. Amaningi amaphupha we-PU, ngokwesiphi, zabelana nokuthi ziqaphe izimbali ezidingekayo ngokuqondisiwe nezinhlobo zesi-steel. Ukusuka kwesikhatsi sokuhlala sonke siphatha kakhle lokulandela indawo yokusebenza ngokubonisa ukuthi abasebenzisi babuyelela umthetho wokuhlola imigomo yabo. Lo msebenzi uvela ngendlela elihle, ngokushesha kakhulu, apho isebenzelo sesikhenkano esisindilekileyo asetshentiswa ngokuba akukho sisisele somgca ofanele, futhi uphawu nokusebenza bafuneka.

Usuku olufanelelwe Okuchasene noma Woven Wire Screens

Izicinge ze-PU zihluke kakhulu ngokushintsha kunye nokukhathala phakathi kwesikrini esikhishweyo, futhi, zihamba izidingo ezindala futhi zingabuyisela. Izimeshi ye-PU, ngezindlela zezimpawu, zihamba ngumthakathi wokuqala eminyaka engu-2 ngaphandle komshado wesayithi esebenzisa isayithi lesikhatsi sama-wire ngokubonisiwe ngamandla yesayithi yokusebenza kwiindlela ezidingekayo. Ukuphumelela bungakho ukusetyenziswa kakhulu lapho amaxesha akhona amanani. Ukuphumelela lokunyuka kuhlanganisa abasebenzi ngokulula kakhulu ngendlela elizidingiwe, ngokwesikhathi sengxoxo nezicwangciso ezinikezeka ngokuba amaxesha asebenzayo akhona. Abahlukanisiwe ngokungasibuyiselwa kunye nokugcwalisa; i-screening ye-PU iyahlukanisanga ngokungasesayithi esilandelana nge-10 ngokusebenzisa ipolyurethane elihluke kakhulu lokushintsha ukuze libuyeleyo kakhulu kunye nokusebenza ngokuphumelela.

Umkangeliso wesihlanu ngokwesiphi ngokulandelana ngesikhombisa

Kwaye ngokuthi uPU ungenze kahle kodwa umlomo ohhlobo, okunene ukufa ngenxa yokuqala lokho, nokuba kunene kulandelana nesiqephu esidingeni sokugcina esifaneleyo. Ukubonakalela oku kungafaneleyo ukusetyenziswa kwisezulwini esidingeni lokugcina esifaneleyo. Lomkhankaso usetyenziswa ukuba umsebenzisi afundise amanani akhe amaningi wamathuluzi, ukuvumela ukuba kube ngenkathi uzame ukukhipha imiswe esidingeni lokugcina. UPU ungenze kahle kodwa umlomo ohhlobo, okunene ukufa ngenxa yokuqala lokho, nokuba kunene kulandelana nesiqephu esidingeni lokugcina esifaneleyo. Lomkhankaso usetyenziswa ukuba umsebenzisi afundise amanani akhe amaningi wamathuluzi, ukuvumela ukuba kube ngenkathi uzame ukukhipha imiswe esidingeni lokugcina. Lomkhankaso usetyenziswa ukuba umsebenzisi afundise amanani akhe amaningi wamathuluzi, ukuvumela ukuba kube ngenkathi uzame ukukhipha imiswe esidingeni lokugcina. Oku kungafaneleyo ukusetyenziswa kwisezulwini lokugcina lokungaphezulu, futhi kungafaneleyo ukusetyenziswa kwisezulwini lokugcina lokungaphezulu, ngokuthi kuhluke izindlela ezininzi zokusebenza kakhulu.

Umbambo Wemali Wepolyester

Uhlobo Lokuzama Ngenkinga Yezilimi

Umkhuthazo wokufiltera esebenziswayo kwezinhlobo zomphumela luhlukelela isigaba esikhoyo ngakwesentanda esinethunywa. Lento yokuhlola lokulandelayo kungafanele ukusetshenziswa kwezinye izinto ezidingiweyo nokuhlala kakhulu. Izicebo ezisebenza zikahle zisetshenziswa kubantu ababekho, futhi le nto yokuhlola kunquma kakhulu kuzama ukusetyenziswa ngezindlela ezithathelwe, kunye neziqhaza lokuhlola lokugcina okukhulu kwiindawo zokusebenza. Ukufunda kwesibhedlela kufanelela ukuhlola nokuvamalisa - ubuqhophiso olunemva kweentsimbi yezilandelana ezidluleyo. Noma ukufakwa kwezilondolozi ezizibuyile ziyahlukanisa ukuba ziqheme ukuthi zifundele iindlela ezidingiweyo ezizofundiswa ngaphandle komphumela.Yesiphi esisebenzisaNgokufaka ukufundelela ukusetshenziswa ngokuthi amagumbi akahle asebenzise umkhuthazo wesibhedlela wabo,wonke amagumbi angasetshenziswa ngokuthi akahle afundele iindlela yesibhedlela yakhe,Akazange asetshenziswa ngokushesha nokuphumeleyo.

Ukuxhasa kweThermoplastic ngeThermoset PU

Ukuphumelela kwezinto zokusetyenziswa phakathi kwezilungiselelo ezithileyo nezilungiselelo ezinethiwekuhlu (PU) kukuhlonipheka ngokubanzi kuzikathalelwa. I-thermoplastic PU iyakwazi ukukhangelana nesibhedlela esikhulu, futhi lokunyelelwano lalayishwa ngokubanzi kumakhetho apha okulingana nokuhlukaniselo oluphansi. Ngaphakathi, i-thermoset PU inakho isibonelo sakhemuka nezinto zomphilo nemiphumela yokusebenza, kuningi ukusetshenziswa apho kukufanele ukusetyenziswa kwezinto ezingazange zihlale kwiinkcukacha ezifaneleyo nokuthiweni oluphila. Ukubonisa ngokubanga labantu ababizwa bafinyelele ukuba bakwazi ukuthintela izinketho ezidingekayo—ukukhetha amaxhobo angahlanganise ngokukhululekile nokuzama ukuthola amandla kanye nokuhlukaniselo, futhi ukushintsha imvume yezikathelo.

Amasistimu Esimngangatho Sokuqasha Ngenqaku le-RFID

Kwisigodlo sokuthuthukisa, umthombo wemileyo we-RFID esihlukene kumeshi yobulawo lisekuphathelwa ngokwesintu. Ngokufundekelwa ukuvavanya nokubhekelana ngephrojekthi lokusetyenziswa kwezinye izinto ezikhulu ngolwandle olunye, amasistimu ase-RFID akhuphela ukungabhedlela nokuhlola okuningi lokusebenza kwisebenzi sokushikiza. Izisistimu ezimbili zikhuphela ukuba zidinga ukusuka kakhulu, ngokugcina ukuthi uhlaziyi wakhiwe ngaphandle komoya ongqondiwe ngokuthi ubhekisisi bethu bekhona. Lomdledlelwano wesiphumo sikhuphela ukuba asikho amagcinane angaphambili, usebenzelo ngokuphumeleleyo kwamaluzi nokuhlala ekudleni kwegunya lokusebenza.

Ukufundziswa kweScreen Mesh Ukusuka nokuhlula

Iindlela zakufundziswa Ezidingiwe Zokuhlola Ukuvamile

Ukusebenzisa imethodi yokuqaphepha ngokubalulekile kuyinhlobo eyakuvunyelwa ngenxa yokusetshenziswa kwekheli lomhlophe lokugcina ukuthi akusebenze ngokukho kakhulu kwiindlela ezininzi. Oku kungabikha ukuba i-tensioning ikusebenze ngokubalulekile ukuze lescreen mesh alihleli futhi alibekisele, futhi umngcele wamathandazo okanye. Ukuthi usetyenziswa lomthetho sithole amanani amaphumeleyo ngokuphephile kwesifundo esincane, sibona ukuthi isebenza ngokubalulekile ukuthola ukusetyenziswa kwe-material ngokuphambili kumgangatho lokusebenza, futhi sikwenza ukuthi kulandelwe isebenza ngokubalulekile kwe-screen fabrics ngokulandelayo kwe-abrasion. Ukusetshenziswa komthetho omncane; U-tensioning nge-tension meters ezicalibrated ngesicwangciso sokusetshenziswa, uzoba ubhekisele ukuthi akukho utshepo olungayazi lokusebenza kumhlophe lokugcina futhi ukusetshenziswa singasebenzi ngendlela enye, ukuze kuhlinzekile ukuthi lemesh lihlinzekile. Isibonelo sokuthi i-tensioning siphumeleyo sithole ukuthi iscreen sisetshenziswa nesisusa ngasemva kwe-operations ngokungakwazi ukufaka imigomo elandelayo.

Amalimi Akuqhathanisa Ngezinye Izimo Zomeme

Amaphrojethi yokuhlola esikhundleniwe kusetyenziselwa ngokuphathelwayo ukuthi i-screen mesh system lihlinywe ngokubonisi. Amaterial angaphakathi, njenge-particles emncane kunye nolwazi olungaphansi, uzoba ukulandela amagatsheni ekwenzeni ukuhlala kwesihlalo esidingene ngendlela efanele kwi-screening performance. Ngokusetshenziswa kwe-guidelines zokuhlola ezindwendwe zokusebenzela nokuthi lapho okuhlola kumaterial okuthiwe ngokuphakeme, lokhu kungabangisekile. Ngiyimfanelo, amaphrojekthi yokuhlola amagumbi amahhala amahhulu kunye ne-techniques zakuhlola zokugcina zinokuba amamesh ayisiblokiswe kumahluko engapheleleyo kunye namahluko emncane. Ngokusetshenziswa kokuhlola kwe-investment-grade solutions, izinesi zazisetshenziswa ukuthi zihlinywe ngokubonisi kunye nokusetshenziswa kwe-performance loss ngalinye lilanga, ukusuka umkhuhlane wokuhlala we-screen mesh systems.

Kuninzi Lapho Ukufaka Ngokwesikhatsi vs Ukufakelwa Kwesikhatsi

Ukuthi uhlalele okanye ushintele amaphepha amacandle ngokwesikhathi sifaniso sokuhlala kuhlu lokusebenza ngenqanawe yezilondolozi ngokucacisa amagama. Lolu hlobo lwezinyathelo zokuhlala kungabizwa ngokubonisa izinethemba zokushintiswa kwezicandle zokuphepha zomncedisi ngokuzenzakalelayo. Uma kunoma isiqephu esingaphambili (asikuyafuneka ukusetyenziswa), ukushintela kufanele. Ngokuba uma i-shake and tear ayithathe kumncedisi omkhulu, ukusuka kwezicandle kufanele nokuthi akukho idown time. Ukukhulula ukushintela nokusuka kwezicandle kungabizwa ukuthi akuyafuneka ukuvuma umculo wokushayela kwezindlela ezindala zokusebenza kwezicandle ngokubalulekileyo kwaye kuphela ukuthi akuyafuneka ukukhupha imali nokuhlola idown time.