Why Polyurethane Screen Mesh Outperforms Traditional Materials

Superior Wear Resistance and Long Service Life in Harsh Conditions

The polyurethane screen mesh works really well in those tough abrasive environments where other materials just can't hold up. What makes this stuff special is how its molecular makeup actually soaks up impacts without getting cut or torn apart, plus it doesn't build up material on the surface. That matters a lot in places like mines and gravel processing plants. Take rubber for instance it breaks down when subjected to heavy weights, and steel gets corroded over time. Polyurethane keeps its strength even when things get wet, acidic, or super hot. Some research indicates that after running for around 10,000 hours through coal slurry, these screens still have about 85% of their original strength left. Compare that to steel which only manages about 40% under similar conditions, and suddenly the benefits become pretty obvious.

Comparison with Metal and Rubber: Durability and Maintenance Advantages

What makes polyurethane stand out is how it manages to be both flexible and rigid at the same time. The material can stretch over 500% before breaking, which is actually three times what we see in standard industrial rubber. This property helps it hold up against cracks when subjected to vibrations. A look at real world applications shows some impressive results. Maintenance costs drop about 60% when using polyurethane instead of metal screens, according to a recent efficiency study looking at operations in Canadian oil sands from 2023. Field operators have noticed something else too: there are roughly 92% fewer unexpected shutdowns happening with polyurethane compared to those old hybrid systems that combine metal and rubber components.

Data Insight: 3-5x Longer Lifespan Than Steel Mesh in Mining Applications

Field data confirms polyurethane’s economic edge:

- Gold ore processing: 3.8x longer lifespan vs. stainless steel (14 vs. 3.7 months)

- Iron ore screening: 5.1x reduced replacement frequency (22 vs. 4.3 months)

- Cost per ton: $0.03 vs. $0.11 for steel mesh over 5 years

These results from a comprehensive performance study demonstrate how polyurethane’s higher initial cost delivers 210-300% ROI through extended service life and consistent throughput.

Maximizing Screening Efficiency and Operational Continuity

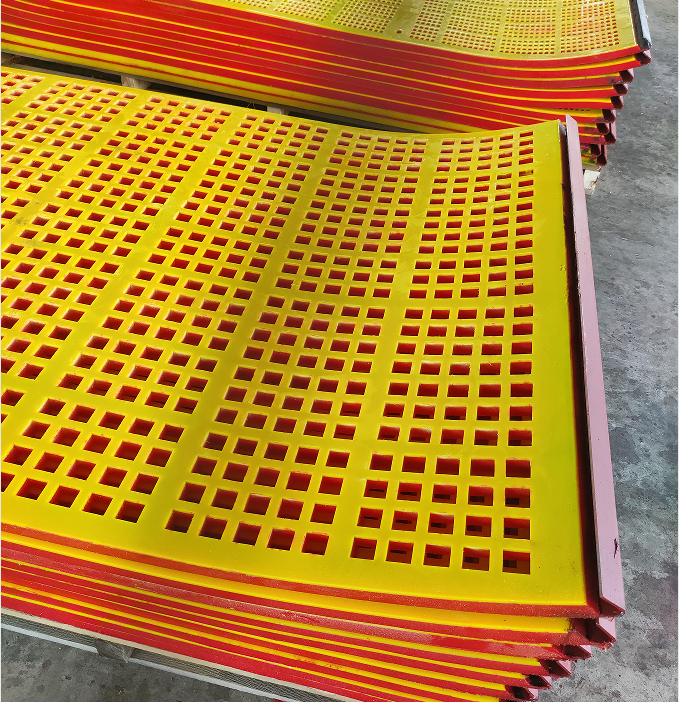

High Aperture Ratio for Improved Throughput and Sieving Accuracy

The open area ratio of polyurethane screen mesh can be around 15% higher compared to traditional steel screens because these meshes are made with precisely molded holes. What does this mean practically? Well, materials pass through at rates between 25 and 40% faster during each screening cycle, yet the actual separation quality remains just as good. Industry studies have found that when these higher aperture ratios are used in aggregate processing systems, they cut down on recirculation problems by about 19%. At the same time, most operators report keeping above 99% efficiency when separating specific particle sizes, which makes these polyurethane screens quite popular among plant managers looking for both productivity gains and consistent results.

Anti-Clogging and Self-Cleaning Properties in Wet and Sticky Conditions

Polyurethane has a water-repelling surface and a flex modulus between 12 to 18 MPa which means it naturally shakes off materials when vibrating. Tests showed something pretty impressive too. When dealing with coal slurry that's over 35% moisture, polyurethane meshes experienced just 7% of the blinding problems compared to rubber screens. What does this actually mean? For industries working with minerals or other tough materials, this self cleaning feature keeps operations running smoothly without constant interruptions. Traditional screens require someone to clean them every hour or so, but polyurethane basically takes care of itself during operation, saving both time and labor costs in the long run.

Consistent Output Through Precision Aperture Sizing

CNC-controlled molding ensures aperture tolerances of ±0.05mm, avoiding the irregular openings common in woven metal screens. Limestone quarry data reveals polyurethane delivers <2% particle size variation across runs, compared to 5-8% with steel. This consistency cuts rework by 30% in precision applications such as glass-grade silica sand production.

Critical Applications Across Mining, Construction, and Recycling

Mining Operations: Scalable and Rugged Performance Under Heavy Loads

The polyurethane screen mesh really stands up to the rough treatment it gets in mining applications. These screens can take on loads exceeding 80 tons per hour without bending or breaking, which is something metal screens just cant handle before they start warping. When we look at actual usage in copper and iron ore processing plants, maintenance crews report needing to replace these screens about 30 percent less often compared to traditional steel options. That means less time spent swapping out damaged equipment during production runs. Another big plus for polyurethane is how it bends instead of breaking when faced with oddly shaped materials coming through the system. This flexibility keeps the material flowing smoothly through the processing line without getting stuck or causing blockages.

Construction Aggregates: Balancing High Throughput with Particle Precision

When sorting gravel and sand, polyurethane gets about 95% accurate on particle sizes, which is good enough for most ASTM and ISO requirements. What makes this material stand out is its aperture ratio around 35 to 45 percent, allowing materials to pass through faster while still maintaining quality control. Field workers have noticed roughly 20% fewer oversized particles when switching from rubber screens, something that really matters in asphalt plants since proper gradation directly impacts how long roads last. Plus, the surface doesn't stick to materials, so sieves stay clear throughout those marathon workdays without needing constant cleaning breaks.

Recycling and Waste Processing: Reliability in Variable Feed Material

Polyurethane works great in recycling facilities when dealing with wet, sticky stuff or materials that tend to wear things down. When used on glass and plastic sorting lines, this material cuts down on how often workers need to clean manually by about half. At the same time, it maintains almost perfect separation rates above 99%. The material also helps reduce cross contamination issues during recycling by around 40% compared to regular wire mesh screens, which means better quality end products from recycled materials. Plus, since polyurethane stands up well against acidic environments, it becomes especially useful for handling electronic waste. Traditional screening materials just can't handle these harsh conditions and tend to break down roughly three times quicker than polyurethane alternatives.

Total Cost of Ownership: Economic Advantages of Polyurethane Screen Mesh

Reduced Downtime and Lower Replacement Frequency

Polyurethane minimizes operational disruptions by lasting 3-5x longer than steel screens in harsh conditions. This durability leads to 63% fewer downtime incidents annually in aggregate plants, saving $740k per site in lost productivity.

| Metric | Polyurethane Mesh | Steel Mesh |

|---|---|---|

| Annual Downtime Hours | 18-22 | 80-120 |

| Replacement Frequency | 24-36 months | 4-8 months |

| Labor Cost/Replacement | $2,800 | $4,500 |

Long-Term Savings Despite Higher Initial Investment

Although polyurethane costs 40-60% more upfront, it yields 40-60% lower total costs over five years. A 2024 materials efficiency study found mining operators recouped their investment within 14 months through reduced labor and sustained production.

Case Study: Efficiency Gains and ROI in a Coal Washing Plant

An industry analysis of a Chinese coal facility highlighted polyurethane’s impact. After replacing rubber screens:

- Throughput rose 22% due to anti-clogging design

- Annual maintenance labor dropped 67%

- ROI was achieved in 18 months

The plant saved $1.2M over three years, extending screen replacements from quarterly to every 28 months.

FAQ

What are the primary advantages of polyurethane screen mesh over traditional materials?

Polyurethane screen mesh excels in wear resistance and maintains its strength in wet, acidic, or hot environments. It also requires less maintenance, reduces operational downtime, and has a longer lifespan compared to steel and rubber screens.

How does polyurethane screen mesh contribute to operational cost savings?

It reduces downtime incidents by 63%, lowers replacement frequency, and cuts down labor costs. Despite higher initial costs, it offers 40-60% lower total costs over five years.

In which industries is polyurethane screen mesh particularly beneficial?

Industries such as mining, construction aggregates, and recycling benefit significantly due to the material's ability to handle heavy loads, provide precision in sizing, and its durability in harsh conditions.

How does polyurethane screen mesh impact the efficiency of a coal washing plant?

Polyurethane's anti-clogging design improves throughput by 22%, reduces maintenance labor by 67%, and helps achieve ROI in 18 months, offering substantial savings over time.

Table of Contents

- Why Polyurethane Screen Mesh Outperforms Traditional Materials

- Maximizing Screening Efficiency and Operational Continuity

- Critical Applications Across Mining, Construction, and Recycling

- Total Cost of Ownership: Economic Advantages of Polyurethane Screen Mesh

-

FAQ

- What are the primary advantages of polyurethane screen mesh over traditional materials?

- How does polyurethane screen mesh contribute to operational cost savings?

- In which industries is polyurethane screen mesh particularly beneficial?

- How does polyurethane screen mesh impact the efficiency of a coal washing plant?