Tonda PU Dewatering Vibrating Screen finds extensive applications across various industries, including mining, coal, construction materials, metallurgy, and chemicals. This high-performance vibrating screen is particularly effective for dewatering, desliming, demineralization, and dry discharge of mining tailings.

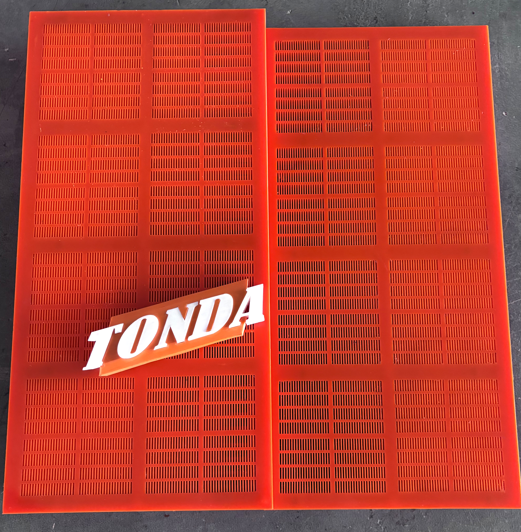

TONDA polyurethane dewatering screen plates are manufactured using premium polyurethane raw materials through a single-pour molding process. Featuring an internal iron skeleton and modular assembly design, these lightweight screen plates offer exceptionally convenient installation and replacement.

Polyurethane dewatering screen mesh is primarily used in industries such as tailings dry stacking, concentrate dewatering, coal slurry dewatering, and carbon slurry separation in coal mines, iron mines, copper mines, and gold mines. By concentrating and dewatering tailings with low useful component content during mineral processing for dry discharge, it reduces tailings storage footprint, minimizes tailings pollution, and eliminates safety hazards. Polyurethane dewatering screen plates serve as critical foundational components for dewatering screens in mining equipment.

Features of Tonda PU Dewatering Screen Plate: Flat surface, fine and open mesh openings, excellent wear resistance, high screening efficiency, and extended service life. As a specialized manufacturer of polyurethane dewatering screen plates, we customize different mesh patterns, screen specifications, and product performance to meet on-site operational requirements based on actual conditions.

Customizable dimensions based on screening equipment and client requirements: 305*305mm, 305*610mm, 500*500mm, 600*600mm etc.

Customizable aperture sizes: 0.1, 0.2, 0.3, 0.5, 0.75, 0.8, etc.

Available mounting methods: expansion bolts, standard bolts, rail mounts, etc., with custom machining available as needed.

Product Advantages:

1. Polyurethane dewatering screen plates offer exceptional wear resistance, significantly outlasting traditional rubber and metal screen plates.

2. Resistant to acids, alkalis, and corrosion, suitable for diverse operating conditions.

3. High-precision screen openings enable efficient classification of materials with varying particle sizes.

4. Low friction coefficient prevents material adhesion and minimizes screen clogging.

5. Polyurethane dewatering screen plates possess inherent elasticity, enabling high throughput, thorough dewatering, and superior efficiency.

6. Polyurethane dewatering screen plates are lightweight, with a density significantly lower than steel. The resulting screens typically weigh only one-third to one-half of equivalent metal screens. Installation methods are simple and versatile, with easy replacement.

7. Polyurethane dewatering screen plates operate with low noise levels, reducing noise pollution.

Tonda PU Dewatering Vibrating Screen finds extensive applications across various industries, including mining, coal, construction materials, metallurgy, and chemicals. This high-performance vibrating screen is particularly effective for dewatering, desliming, demineralization, and dry discharge of mining tailings.

Dewatering screens are specialized for solid-liquid separation (e.g., coal slurry dewatering, tailings dry discharge), with their core function being moisture removal from materials.

The core metric for dewatering screens is dewatering efficiency (such as the moisture content after coal slurry dewatering), followed by screening accuracy.

Screen panel size: 305*305、 305*610 、 610*610 、or customized size based on your drawing or inquiry details.

Installation methods:Pin and sleeve,Rail fixing, bolt and nuts, strips

Color: could be customized based on Pantone code as buyer confirmed

Aperture size:

Size(mm) |

0.075 |

0.1 |

0.15 |

0.2 |

0.25 |

0.3 |

0.5 |

0.6 |

0.7 |

0.85 |

1 |

1.18 |

1.4 |

2 |

mesh |

200 |

140 |

100 |

70 |

60 |

50 |

35 |

30 |

25 |

20 |

18 |

16 |

14 |

10 |

Advantages of TONDA PU dewatering screen panel:

1. offer exceptional wear resistance, significantly outlasting traditional rubber and metal screen plates.

2. Resistant to acids, alkalis, and corrosion, suitable for diverse operating conditions.

3. High-precision screen openings enable efficient classification of materials with varying particle sizes.

4. Low friction coefficient prevents material adhesion and minimizes screen clogging.

5. It possess inherent elasticity, enabling high throughput, thorough dewatering, and superior efficiency.

6. It is lightweight, with a density significantly lower than steel. The resulting screens typically weigh only one-third to one-half of equivalent metal screens. Installation methods are simple and versatile, with easy replacement.

7. Low noise levels, reducing noise pollution.