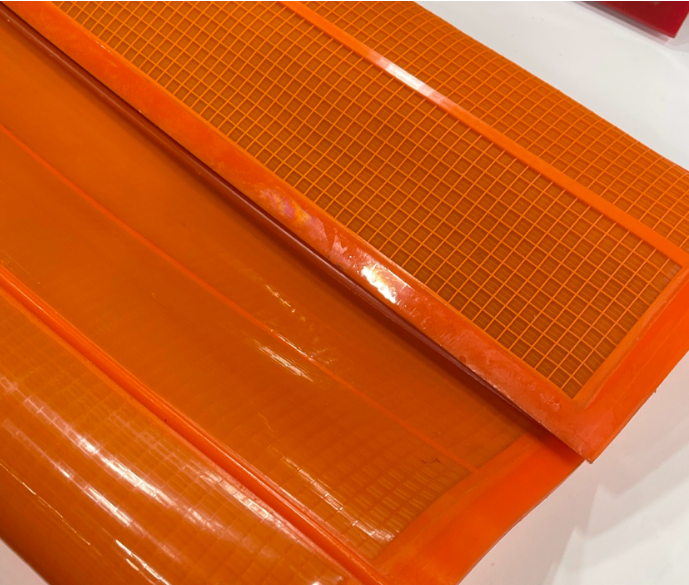

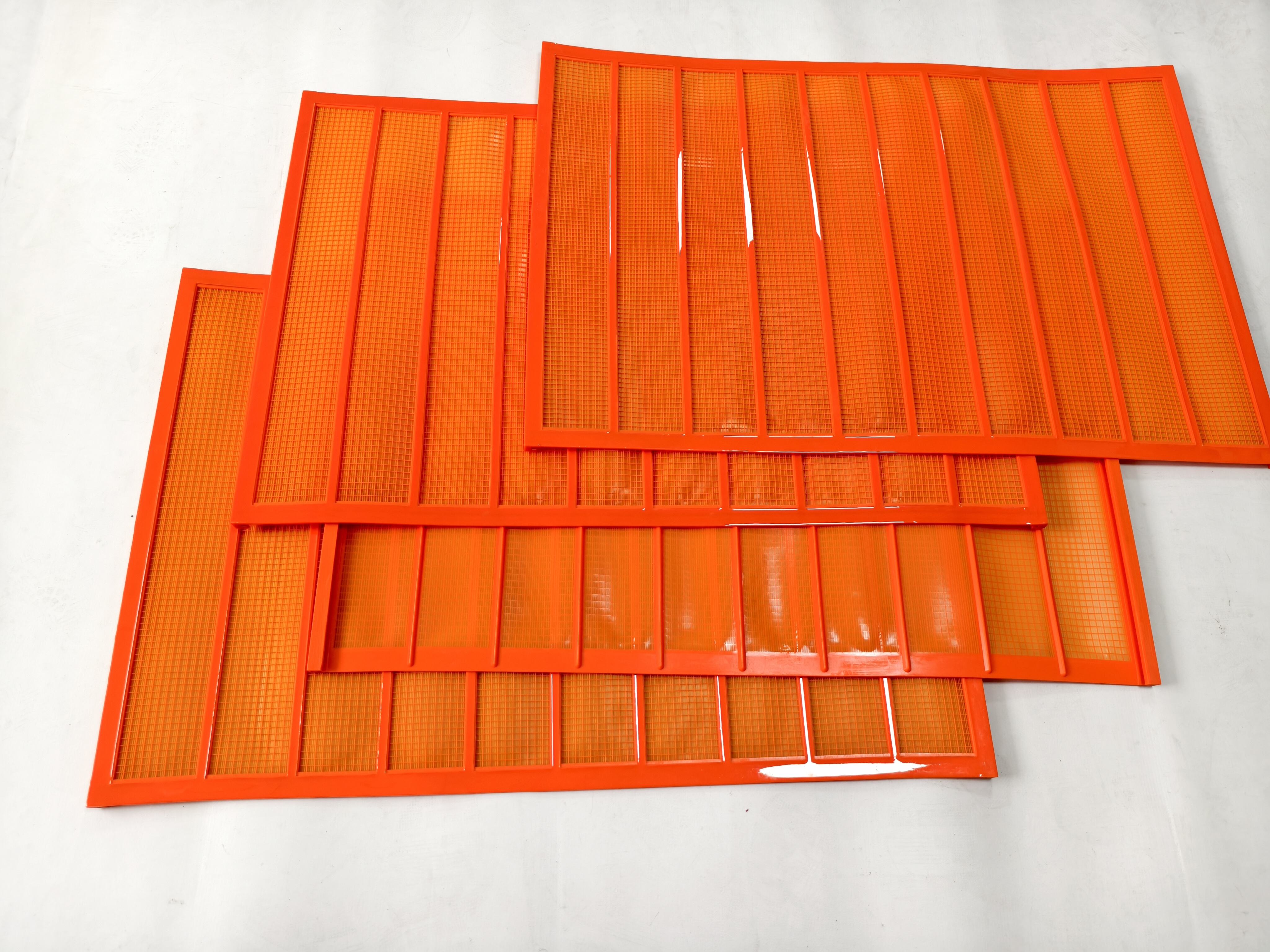

Polyurethane high-frequency fine screen is a high-strength, high elasticity, and high wear resistant fine screen suitable for various high-frequency screens. The screen gap is usually 0.075-3mm, and the opening rate can reach 28-45%. The product is widely used in industries such as metallurgy, mining, coal, and non-ferrous metals, with a service life of 3-6 months.

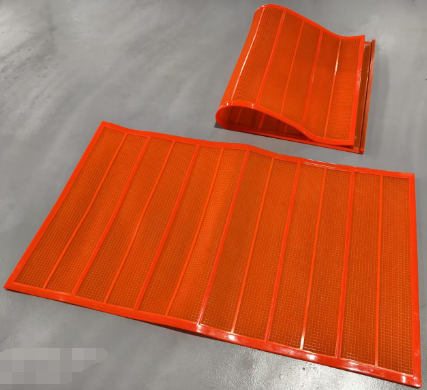

Polyurethane high-frequency screen mesh, also known as flexible polyurethane fine screen mesh, is made from high-elasticity polyurethane material with an internal high-strength fiber skeleton to enhance tensile strength. Its hook-edge design facilitates easy installation and removal. This screen mesh boasts excellent physical and mechanical properties: high strength, high elasticity, and high wear resistance. Common specifications include 1045*700; 1245*700, etc., with mesh openings ranging from 0.075 to 3mm, customized size is optional.

Features of Flexible Polyurethane Fine Screen Mesh:

1. High Open Area Ratio: High open area ratio (32%-42%) minimizes clogging, particularly effective for handling moist fine-grained materials, delivering high screening efficiency and large processing capacity.

2. Wear resistance: Flexible polyurethane screens exhibit high abrasion resistance, maintaining excellent screening performance during prolonged, high-frequency operation.

3. High strength: The polyurethane material used in these screens possesses exceptional strength and toughness, withstanding significant tensile forces and impacts to ensure stability and longevity.

4. Corrosion Resistance: Flexible polyurethane screens exhibit strong resistance to most acids, alkalis, and salts, enabling operation in corrosive environments.

5. Superior Filtration: The fine, uniform apertures effectively filter minute particles, significantly enhancing product quality.

Applications of Flexible Polyurethane Fine Screens:

Widely used in the mining industry, they can be paired with various electromagnetic vibrating high-frequency screens, composite vibrating high-frequency screens, and stacked high-frequency screens, and can replace imported counterparts. Currently, this product is extensively applied in the fine screening, grading, and de-mediation of metals and non-metals such as iron ore, coal, tin, tungsten, tantalum-niobium, lead, quartz ore, and zinc ore.

TONDA brand factory is a professional polyurethane screen mesh manufacturer. We have established long-term supply agreements with major domestic mines and vibrating screen manufacturers, and export to over 20 countries and regions worldwide, including Australia, the United States, and Chile. TONDA’S polyurethane screen meshes feature comprehensive specifications, exceptional durability, and extended service life, earning recognition and trust from both domestic and international clients.

|

|

|

|

|

Polyurethane high-frequency fine screen is a high-strength, high elasticity, and high wear resistant fine screen suitable for various high-frequency screens. The screen gap is usually 0.075-3mm, and the opening rate can reach 28-45%. The product is widely used in industries such as metallurgy, mining, coal, and non-ferrous metals, with a service life of 3-6 months.