How Anti-Clogging Properties Improve Screening Efficiency

Surface Energy and Elastic Recovery: The Science Behind Clog Resistance

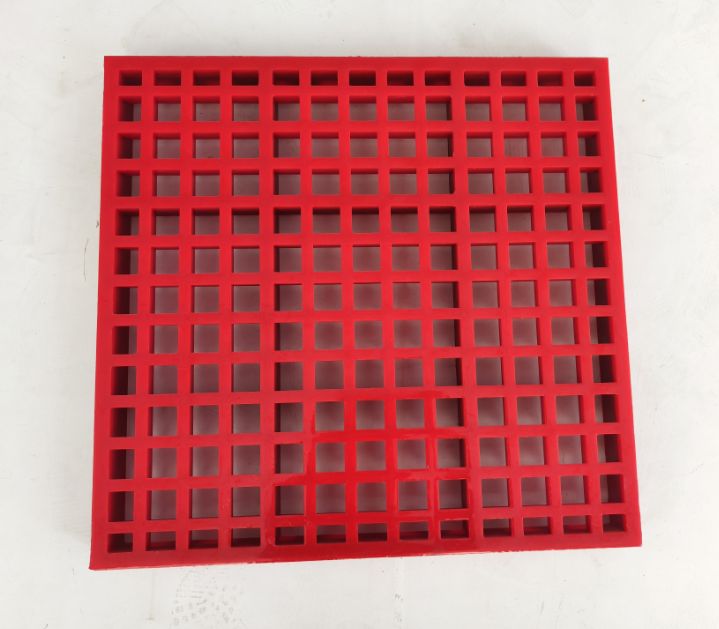

The polyurethane screen mesh stands out because it fights against material buildup thanks to its low surface energy properties and good elastic memory. What makes this material special is how its hydrophobic nature keeps moisture from sticking, and when something gets deformed, it bounces back quickly enough to shake loose any particles that might be stuck. These two features work together to stop apertures from getting blocked, especially important in tough situations involving clay rich slurries. Industry research points to around 30 percent less blinding issues compared to traditional rigid screens. Plus, the high level of elastic recovery (over 95% according to ASTM D2632 standards) actually turns vibration into a cleaning action, which helps keep things flowing smoothly during coal washing and aggregate processing tasks without much downtime.

Polyurethane vs. Stainless Steel and Rubber: Clogging Performance in High-Moisture Applications

In wet screening environments, polyurethane outperforms stainless steel and rubber due to superior material properties:

| Property | Polyurethane | Stainless Steel | Rubber |

|---|---|---|---|

| Moisture Rejection | Hydrophobic surface | Adhesion-prone | Moderate absorption |

| Elastic Recovery | >95% rebound | Rigid (no rebound) | Slow recovery |

| Long-term Clogging | 40% reduction | Frequent pegging | Progressive blinding |

These advantages translate directly into operational efficiency. Polyurethane maintains screening performance under continuous slurry flow, whereas steel screens require frequent shutdowns for cleaning. Field data show up to 30% less downtime in mineral processing compared to rubber alternatives—especially critical when handling damp bulk solids with high moisture content.

Self-Cleaning Mechanism in Wet and Sticky Screening Conditions

Dynamic Vibration Response and Material Rebound in Clay-Rich Coal Slurry

Polyurethane screen mesh uses dynamic vibration response to resist clogging in high-moisture conditions. When processing clay-rich coal slurry—where traditional screens often fail—its elastic recovery generates micro-rebound effects that eject sticky materials. At vibration frequencies between 800—1200 RPM, this self-cleaning action intensifies, preventing particle adhesion and maintaining separation efficiency.

Key mechanisms include:

- Surface energy reduction: The hydrophobic surface limits water film formation, reducing interparticle bonding

- Differential rebound: Clay particles (density: 1.8—2.6 g/cm³) rebound more slowly than coal (1.3—1.5 g/cm³), enhancing stratification and separation

Above 8% moisture content, the screen’s stored elastic energy triggers a “snap-back” effect during vibration, expelling trapped fines without manual cleaning. This capability sustains throughput in high-capacity coal washing operations—often exceeding 200 tons/hour—while improving separation accuracy by up to 20% over rigid alternatives.

Impact on Coal Washing Plant Throughput and Operational Efficiency

Screen clogging creates significant bottlenecks in coal processing. Blocked apertures reduce throughput and increase energy use. Anti-clogging polyurethane screen mesh mitigates these issues with moisture-repelling surfaces and elastic rebound, enabling continuous operation. Plants achieve 15—30% higher tonnage rates and lower power consumption, all without frequent maintenance interventions.

Case Study: 32% Throughput Increase and 18-Month ROI in a Coal Washing Plant

A coal washing facility in Central Appalachia processing high-clay bituminous coal experienced screen blockages every 90 minutes, severely limiting output. After replacing rubber screens with polyurethane mesh, unplanned downtime dropped by 80%, and throughput increased by 32%. Key improvements included:

| Improvement Metric | Gain |

|---|---|

| Material processed | +17,500 tons/month |

| Energy consumption | -12% ($8,100 monthly savings) |

| Screen replacement frequency | Extended from 3 to 11 months |

The $740,000 retrofit investment yielded $325,000 in annual savings, achieving full return on investment in 18 months. Additionally, improved screening consistency raised coal purity by 9%, allowing the facility to command premium market pricing—highlighting how advanced materials drive both operational and economic gains in high-moisture environments.

Balancing Flexibility and Durability in High-Throughput Applications

When Does Polyurethane’s Flexibility Become a Limitation?

Polyurethane works great for absorbing impacts and stays clean on its own, but there's a catch when things get really busy in production environments. When the system runs non-stop with loads above about 500 tons per hour, all that flexibility becomes a problem. The material starts to deform before it should, which messes up how accurate the screening process is and shortens how long the equipment lasts overall. We see this happen most when the impact forces go past around 50 kilojoules per square meter, especially if dealing with gritty or rough materials. The constant pounding wears down the rebound characteristics over time and causes faster deterioration right where the pressure points are highest.

When materials start to lose their strength after prolonged use, this can really impact how well they separate different substances. That's why many tough industrial situations call for something special these days. Combining polyurethane's ability to resist blockages with added structural support creates what works best in practice. The result keeps all that good flexibility we want from elastic materials but adds much needed stiffness and lasts longer too. Equipment runs smoothly for longer periods, maintains accuracy levels, and doesn't slow down production rates like some alternatives might do.

FAQ

What is the main advantage of polyurethane screen mesh?

Polyurethane screen mesh offers anti-clogging properties due to its hydrophobic surface and high elastic recovery, which enhances screening efficiency in high-moisture conditions.

How does polyurethane compare to stainless steel and rubber in terms of clogging performance?

Polyurethane surpasses stainless steel and rubber because of its moisture-rejecting and rebound properties, reducing downtime and improving operational efficiency.

Can polyurethane screen mesh maintain high throughput in coal washing plants?

Yes, polyurethane screen meshes promote continuous operation with higher throughput rates and lower energy consumption by reducing screen blockages and maintenance needs.