How Screen Media Tension Affects Polyurethane Screening Performance

The mechanics of tension distribution in flex-mat polyurethane screen media

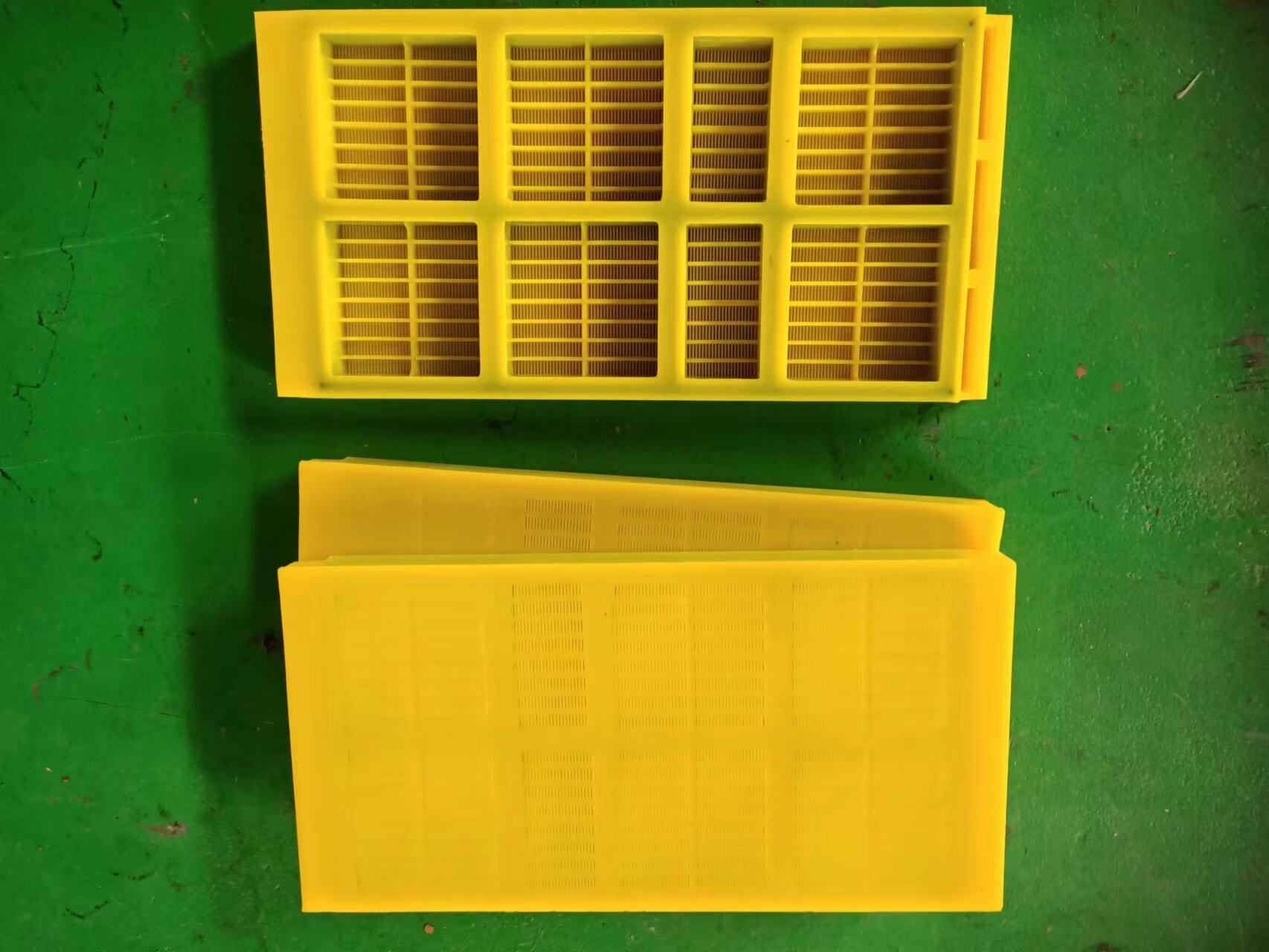

The polyurethane screen media needs just the right amount of tension spread out evenly so it stays strong while running. What makes this material special are its elastic qualities that let stress move around the surface naturally. Those interconnected polymer strands actually soak up pressure at specific points where force builds up. When everything is properly tightened, what starts as simple flat panels becomes something that responds to vibrations, making sure every part of the flex mat shares the workload fairly. If tension isn't balanced though, certain spots get overworked fast creating these trouble areas we call hotspots. That's why getting installation right matters so much for longevity.

Impact of dynamic loads on tensioned polyurethane screens under operation

Polyurethane screens face all sorts of operational stresses during normal use, which makes maintaining proper tension quite challenging. When materials pass over the screen surface, sudden impacts create temporary tension surges that can reach around 28 percent higher than what's normally expected. Whether a screen returns to its original tension state really comes down to two main factors: the hardness rating (durometer) of the material itself and how well it's been reinforced structurally. Areas that get too much stress show noticeable thinning over time. Field tests indicate losses of approximately 0.15 millimeters per month in spots where impacts are most frequent. This kind of wear clearly shows why uneven tension distribution leads to faster breakdown of the screening material.

Strategy: Ensuring uniform tension to prevent edge wear and deformation

Achieving uniform tension requires a systematic approach:

- Frame preparation with <3 mm/m² flatness tolerance

- Progressive bolt torque sequencing (25% increments to final spec)

- Laser-assisted tension mapping during installation

As outlined in industry-standard installation techniques, post-installation tension checks every 250 operational hours reduce edge wear by 60% compared to unmonitored systems. Operators using tension-monitoring wear strips report 38% longer media life in coal screening applications.

Performance Benefits of Properly Tensioned Polyurethane Screen Media

Enhanced Wear Resistance and Extended Service Life Under Consistent Tension

Proper tensioning reduces material fatigue by up to 60%, mitigating premature cracking and elongation common in loosely installed systems. A [2022 Mining Technology Journal study] found that tensioned polyurethane screens last 40% longer than non-tensioned equivalents in high-impact mineral processing. The elastomeric nature of polyurethane allows recovery after particle impacts, while consistent tension prevents permanent deformation at anchor points.

Improved Flexibility and Vibration Absorption in Tensioned Systems

Tensioned polyurethane screens absorb 30-50% more vibrational energy than rigid alternatives, reducing harmonic stress on equipment. This flexibility supports dynamic movement essential for separating wet and sticky materials, where continuous flexing aids oversize discharge. With a modulus of elasticity 8-10 times higher than rubber, polyurethane maintains structural integrity over repeated bending cycles, lowering maintenance costs by an average of $18/ton processed.

Data Point: 40% Longer Wear Life vs. Loosely Installed Modular Panels (Mining Technology Journal, 2022)

Field trials show tensioned polyurethane screens achieve 18-24 months of service in coal processing-a 40% improvement over untensioned modular panels. This longevity stems from minimal aperture distortion (<2% dimensional change after 5,000 hours) and elimination of fastener-related wear. The same study notes tensioning reduces replacement costs by $7.50/square meter annually through less downtime and labor.

Reduced aperture clogging through enhanced surface movement under tension

Properly tensioned polyurethane screen media generates micro-flexing that disrupts near-size particles attempting to lodge in apertures. When tension meets manufacturer specifications, surface agitation increases by 15-20%, significantly reducing clogging. A 2023 Canadian Mining Journal study confirmed this effect leads to fewer blinding incidents in mineral processing operations.

Tension-induced oscillation as a mechanism to prevent particle lodging

The inherent elasticity of polyurethane converts standard vibrations into high-frequency oscillations when properly tensioned, creating a self-cleaning effect. Maintaining tension within 10% of recommended levels amplifies this oscillation by 40%, making it highly effective against sticky or damp materials prone to pegging, as noted in industry installation guidelines.

Case Study: 30% reduction in blinding incidents at an aggregate processing plant

A gravel processing company saw a drop of around 30% in monthly blinding problems once they started using tension monitoring on their polyurethane screening decks. They installed wireless tension sensors throughout the system and began tweaking clamp pressures according to what the flow data was showing them in real time. The results were pretty impressive too - screen life actually lasted about 22% longer without sacrificing much at all when it came to uptime, which stayed above 98% during all three daily shifts. What this shows is that keeping tabs on tension levels makes a big difference for operations running at scale.

Polyurethane vs. Woven Wire Mesh: Performance Under Tension

Vibration Response and Separation Efficiency: Polyurethane Tensioned Screens vs. Woven Wire

Tensioned polyurethane screens distribute vibrational energy uniformly, resulting in 20% better separation efficiency than woven wire in medium-to-coarse applications (Mineral Processing Quarterly, 2023). Their flexibility maintains consistent aperture geometry under load, avoiding the rapid deformation typical of metal mesh under cyclic stress.

Situations Where Woven Wire Mesh Still Outperforms Polyurethane

Woven wire remains preferable in high-temperature environments exceeding 150°C—beyond polyurethane’s thermal limits—and in ultra-fine separations requiring sub-100μm apertures. It also performs well in static screening of non-abrasive materials due to its higher open area percentage.

Cost-Benefit Paradox: Higher Upfront Cost of Polyurethane Offset by Lower Maintenance and Downtime

Woven wire might cost 40 to 60 percent less upfront, but when it comes to wear and tear in harsh environments, polyurethane lasts way longer. Some plants have seen their replacement needs drop by around three times what they were before. Take one aggregate operation from late 2024 or early 2025 as an example they cut down on annual downtime expenses by roughly 30% once they made the switch to those tight tensioned polyurethane setups. And let's not forget about those modular designs either. They really speed things up during installation. Looking at the big picture over time, most mineral processors find that polyurethane pays for itself somewhere between 18 and maybe 24 months after installation depending on how intense the conditions get day to day.

Applications and Best Practices for Tensioned Polyurethane Screen Media in Mining

Demand Drivers in Abrasive Ore Environments for Polyurethane Tension Screen Adoption

Mining operations dealing with abrasive materials such as iron, copper, and gold frequently encounter problems with traditional screening equipment breaking down too soon. The material known as polyurethane actually works better than metal options because it can stretch and handle repeated impacts without wearing out so fast. According to field reports from several mines, those switching to tensioned polyurethane saw around 42 percent reduction in unexpected shutdowns compared to their old wire mesh setups. What makes this material stand out is how well it holds up when subjected to heavy loads constantly changing direction. That's why many large scale mining sites have adopted it particularly during the initial crushing phase where rock fragments typically measure over 50 millimeters across.

Field Data: 25% Increase in Throughput at a Copper Processing Facility Using Flex-Mat Systems

A North American copper mine achieved significant improvements after adopting tensioned polyurethane screens:

- Throughput increased by 25% due to reduced blinding

- Panel replacements dropped from biweekly to quarterly

- Energy consumption per ton processed decreased by 18%

These results align with findings from the Mining Technology Journal (2022), which identified optimized tension as a key factor in maximizing screening efficiency for sulfide ores.

Importance of Correct Installation and Routine Inspection to Maintain Optimal Tension

Improper tensioning negates polyurethane’s performance benefits. Critical protocols include:

- Using laser-guided tools to ensure ±2% tension uniformity

- Conducting fastener torque checks every 250 operating hours

- Re-tensioning panels after the first 48 hours to account for settling

Facilities following these practices report 30% longer screen life compared to those using ad hoc methods.

Strategy: Aligning Tension Levels with Feed Material Characteristics for Peak Performance

| Material Type | Recommended Tension Range | Adjustment Frequency |

|---|---|---|

| High-abrasion ores | 18—22 N/mm² | Biweekly |

| Sticky aggregates | 15—18 N/mm² | Weekly |

| Fine-grained minerals | 12—15 N/mm² | Monthly |

Calibrating tension to feed characteristics prevents over-stressing while maintaining optimal flow rates. Leading facilities using this approach achieve 95% screening efficiency across diverse mineral blends.

FAQ

Why is tension important for polyurethane screen media?

Tension is crucial because it ensures uniform stress distribution across the screen media, preventing hotspots and prolonging the lifespan of the screen.

How often should tension checks be performed?

Post-installation tension checks should be performed every 250 operational hours to reduce wear and extend the lifespan of the screen media.

What are the benefits of tensioned polyurethane screens over woven wire?

Tensioned polyurethane screens offer better wear resistance, vibration absorption, and longer lifespan compared to woven wire, especially in harsh environments.

What is the recommended tension range for different materials?

The recommended tension range varies: high-abrasion ores require 18—22 N/mm², sticky aggregates need 15—18 N/mm², and fine-grained minerals should have 12—15 N/mm².

How does proper tensioning prevent aperture clogging?

Proper tensioning induces surface movements and oscillations that disrupt particle lodging in apertures, hence reducing aperture clogging.

Table of Contents

- How Screen Media Tension Affects Polyurethane Screening Performance

- Performance Benefits of Properly Tensioned Polyurethane Screen Media

- Preventive Maintenance Through Optimized Tension Control

- Polyurethane vs. Woven Wire Mesh: Performance Under Tension

-

Applications and Best Practices for Tensioned Polyurethane Screen Media in Mining

- Demand Drivers in Abrasive Ore Environments for Polyurethane Tension Screen Adoption

- Field Data: 25% Increase in Throughput at a Copper Processing Facility Using Flex-Mat Systems

- Importance of Correct Installation and Routine Inspection to Maintain Optimal Tension

- Strategy: Aligning Tension Levels with Feed Material Characteristics for Peak Performance

- FAQ