The WS85 polyurethane screen panels are designed to excel in the most abrasive and high-impact screening environments. Utilizing advanced polyurethane formulations and reinforced structural design, these panels deliver unmatched longevity and efficiency for industries requiring rigorous material separation. Ideal for mining, aggregate processing, and recycling, the WS85 series ensures consistent performance under heavy loads and harsh conditions.

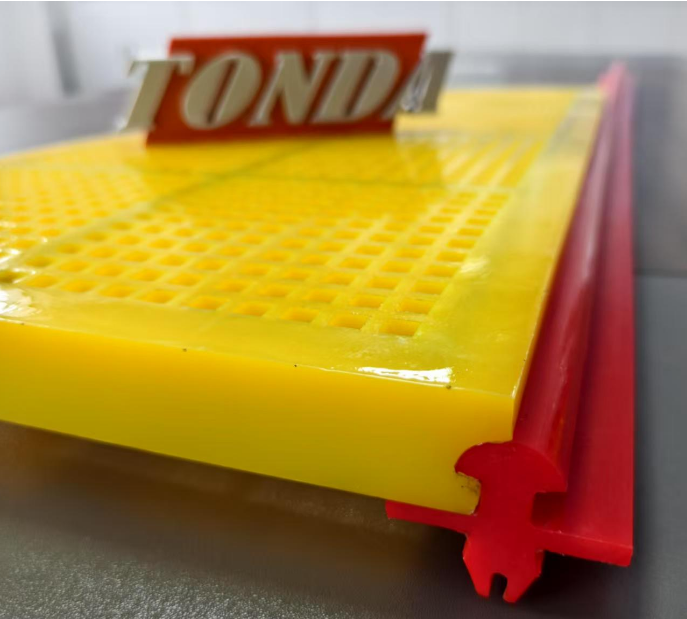

Polyurethane Screen Plates

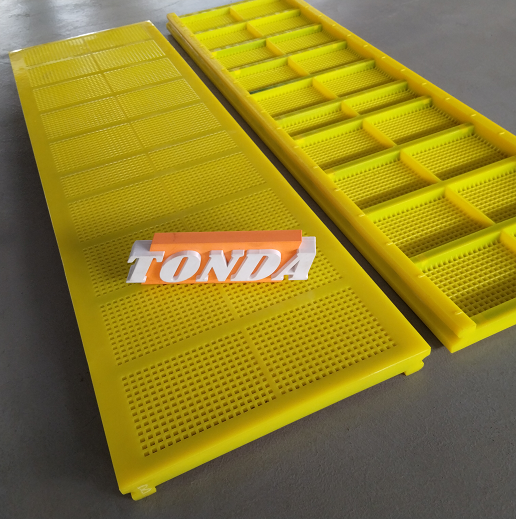

TONDA brand polyurethane screen plates are manufactured using premium polyurethane raw materials through a single-pour molding process. Featuring an internal iron skeleton and a modular assembly design, these lightweight plates offer exceptionally convenient installation and replacement.

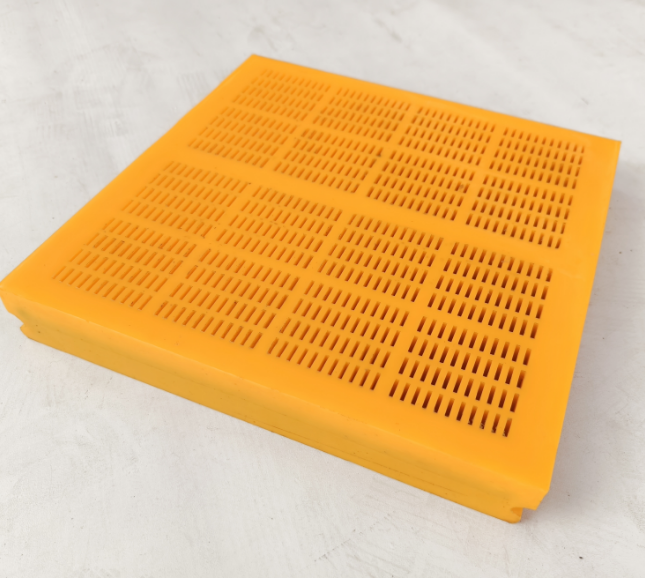

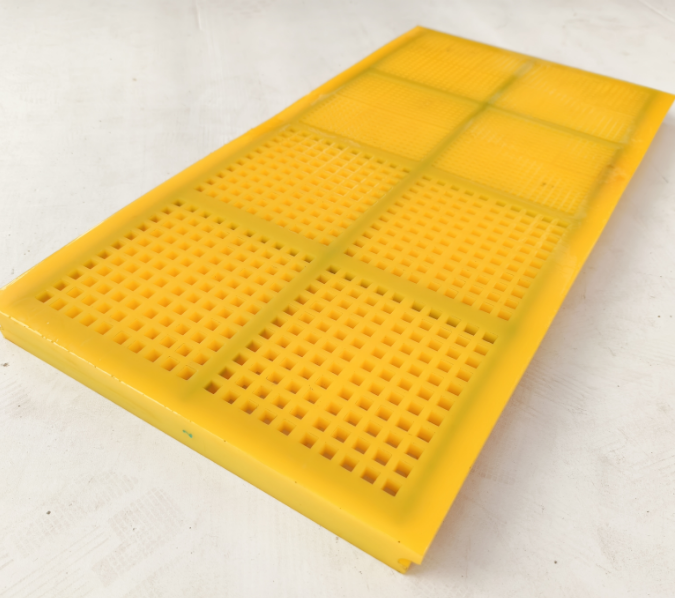

These plates offer high elasticity, exceptional wear resistance, impact toughness, and extended service life. They are widely used in metallurgy, coal, chemical, and construction materials industries for ore washing, screening, classification, slag removal, desliming, and dewatering. Mesh sizes ranging from 0.1 mm to 80 mm can be customized. Mesh patterns include slotted, square, elongated, round, and VR anti-clogging holes. Screen surfaces can be manufactured in standard hardness or dual-hardness configurations.

As a specialized manufacturer of polyurethane screen plates, we customize mesh patterns, screen specifications, and product performance to meet specific on-site operational requirements.

| WS85 | WS85 sieve plate-300*305 | WS85 sieve plate-300*610 |

|

|

|

| WS85 sieve plate-300*800 | WS85 sieve plate-300*1000 | WS85 sieve plate-300*1220 |

|

|

|

Key Features

✅ Superior Wear & Tear Resistance

8–10x Longer Lifespan: Outperforms conventional rubber and steel screens in abrasive applications such as iron ore and granite processing.

Optimized Hardness: Shore A 70-90 (±5) provides ideal balance between flexibility and resistance to cutting, tearing, and impact.

Reinforced Edges: Steel-reinforced borders prevent edge damage during high-frequency vibration.

✅ Anti-Clogging & High Efficiency

Smooth Surface Design: Reduces material adhesion for sticky substances like wet coal or clay.

Open-Area Optimization: Customizable aperture patterns (round, square, slotted) from 1mm to 80mm to maximize throughput.

✅ Versatile Customization

Panel Dimensions: Tailored sizes up to 300mm - 1200mm, with thickness options from 30mm to 60mm.

Temperature Resilience: Operates reliably in extreme conditions (-30°C to +100°C).

Applications

Mining & Quarrying: Efficiently screens iron ore, copper, limestone, and crushed aggregates.

Coal Preparation: Handles wet or sticky coal with minimal clogging.

Recycling Plants: Separates construction waste, plastics, and metals.

Chemical Industry: Resists corrosion from acids, alkalis, and solvents.

Technical Specifications

Maximum Feeding Particle Size Range |

0.1-250mm |

Maximum Drop Height |

300-650mm |

Applications |

Comprehensive wet/dry screening |

Hardness |

Shore A 70/80/ 90(±5) |

Thickness |

30-60mm |

Certifications |

ISO 9001, CE, RoHS |