Understanding Mesh Opening Size in Screening Systems

Defining aperture dimensions and measurement standards

The aperture dimensions basically describe how big and what shape the holes are in a mesh material, typically given in millimeters or microns. Groups such as ASTM have set standards for these measurements so everyone gets the same specs no matter where they're used. When it comes to actually checking these dimensions, there are several methods available. One common way is looking at the mesh under an optical microscope which lets technicians see exactly what those openings look like up close. Another method involves laser diffraction technology that measures how light scatters when passing through the mesh openings. Getting accurate readings matters a lot since small changes in mesh size can really impact how well something filters out particles and ultimately affects whether the finished product meets quality standards.

Relationship between mesh geometry and particle retention

The geometry of a mesh matters a lot when it comes to keeping particles out during screening operations. The actual shape of those openings - squares, rectangles, circles - plays a big role in determining how materials pass through and what gets caught. These different shapes actually change how stuff moves across the screen and affects retention rates too. Some research showed that changing the way meshes are designed can boost retention by around 25 percent in some cases. That kind of data really highlights why picking the right mesh design is so important for getting good results from screening applications. It's not only about what stays behind though. Getting the geometry right also makes the whole screening process work better overall.

Impact of Mesh Opening Size on Separation Efficiency

Precision requirements for different material grades

Getting good separation results when screening materials depends a lot on picking the right mesh openings for different material types. Fine powders need smaller mesh holes to work properly, while bigger stuff like aggregates works better with coarser meshes. Most industries have established guidelines about what particle sizes work best with particular materials, so mesh choices match up with specs and keep product quality consistent. We've seen plenty of cases where companies picked the wrong mesh size and ended up losing significant amounts of material during processing, which really drives home how important it is to get those mesh specs right. Following standard practices helps manufacturers maintain efficient separation processes no matter what kind of materials they're working with day to day.

Throughput vs. accuracy trade-offs in classification

Screening operations always involve a tricky balance between getting stuff through quickly and making sure what comes out is actually what we want. When operators enlarge those mesh openings, they generally see faster throughput since more material passes through in shorter periods. But here's the catch: bigger holes mean smaller particles sneak through too, which messes up the whole classification process. Some research shows if someone increases mesh opening size by around 10%, they might get a 30% jump in throughput, though accuracy typically drops about 15%. Finding the sweet spot matters a lot, particularly in industries where both speed and precision count. Most experienced technicians run simulations testing various mesh setups before finalizing anything. These virtual tests save money and headaches down the line while still maintaining product quality standards across different production runs.

Key Factors Determining Optimal Mesh Specifications

Material Characteristics and Particle Size Distribution

When looking at material properties like density, shape, and surface texture, these really matter when figuring out what kind of mesh works best. The way these traits interact determines if the material fits well through various mesh sizes for proper separation. Take it from experience working with industrial sieves: heavier stuff often needs bigger holes so things don't get stuck. But then again, oddly shaped particles actually work better with smaller meshes because they tend to bounce around more until they separate completely. It's all about finding that sweet spot between what the material wants and what the equipment can handle.

Particle Size Distribution or PSD analysis tells us exactly what's going on with different sized particles in any given material. The thing about this kind of analysis is that picking the right mesh size based on actual PSD data makes all the difference for separation processes. When researchers look at materials where mesh sizing matches the natural particle distribution, they consistently see better results across the board. Practical experience shows that getting this alignment right between mesh and particle sizes leads to much smoother operations and fewer headaches down the line.

Vibration Intensity and Screening Duration Effects

The strength of vibrations really matters for how well a mesh works. Boosting vibration levels tends to make materials pass through the mesh much easier, which means better throughput overall. But there's a catch too. Higher vibration usually means the mesh needs bigger openings to handle all that movement without getting clogged up. Finding the right balance between vibration strength and mesh size becomes pretty important if we want our separation process to work properly without wasting time or materials.

Keeping track of how long materials spend on the screen matters just as much as picking the right mesh size for the job. Finer meshes actually handle longer screening times better since their structure holds up during extended processing without losing effectiveness. The numbers back this up too - adjusting not only how hard the screen vibrates but also how long it runs makes a real difference in separating materials properly. These small changes in operation parameters can boost overall system performance quite a bit, which explains why many plants focus so much attention on getting these details right.

Polyurethane Advantages Over Traditional Screening Media

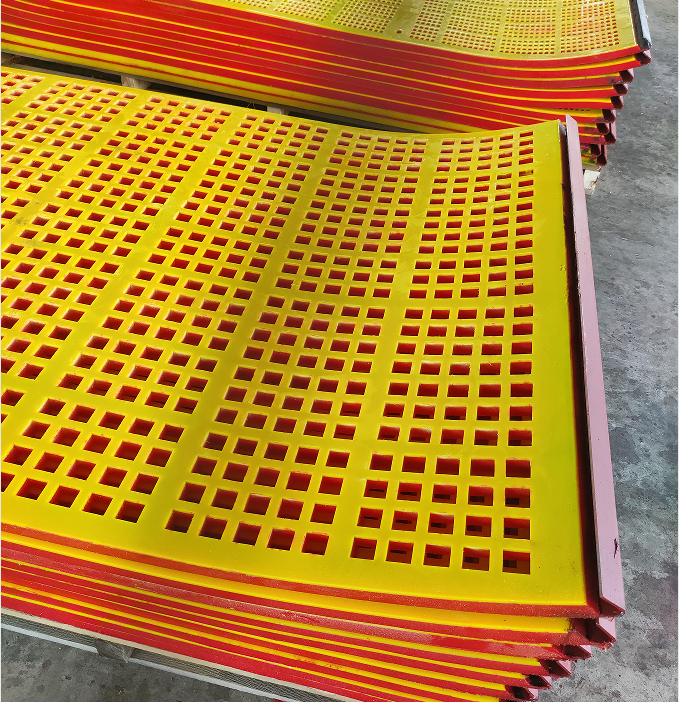

Consistent Aperture Maintenance under Stress

The introduction of polyurethane screens has made a real difference in keeping those apertures consistent when things get tough. Traditional mesh materials tend to warp and stretch after prolonged exposure to stress, but polyurethane holds its shape much better. What this means for actual operations is that screening remains accurate throughout long production runs without needing frequent adjustments. When standard meshes start to degrade, their openings either shrink or expand unpredictably, messing up the whole separation process. Field data shows that these polyurethane alternatives typically last longer than steel counterparts in demanding industrial settings. Plants that switched to them report spending less money overall because they don't have to replace screens as often or deal with downtime from inconsistent screening results.

Comparison with Steel Mesh Wear Patterns

Steel mesh screens tend to break down pretty quickly when exposed to abrasive materials, which means they need replacing all the time and creates a lot of downtime for operations. On the other hand, polyurethane stands out as much tougher stuff that lasts way longer under similar conditions. Research shows that these rubber-like materials stay effective roughly 30 percent longer than traditional steel options in most industrial settings, making them both more efficient and cheaper over time. Less wear and tear also cuts down on tiny particles getting into products during processing, something that matters a lot in food manufacturing, pharmaceuticals, and chemical plants where purity standards are strict. Switching to polyurethane makes sense for companies looking to keep production running smoothly without constant stoppages for maintenance.

Innovations in Fiber Filter Mesh Integration

Hybrid designs combining polyurethane durability

When fiber filter mesh gets combined with polyurethane, it really boosts how long screening systems last and makes them much more flexible too. We see these mixed material setups gaining popularity fast among manufacturers working in tough environments where equipment needs to stand up to rough treatment day after day. What works so well is simply putting two different materials together – each one complements what the other lacks. Some recent tests show that these hybrid screens actually last longer between replacements and need less frequent upkeep than traditional options. For companies looking at their bottom line, this means serious savings over time while still getting better results from their screening operations.

- The integration provides enhanced lifecycle performance.

- Hybrid designs are favored for resilience in demanding conditions.

- Analytical reviews show increased lifespan and reduced maintenance frequency.

Enhanced anti-blinding through composite structures

The addition of composite structures to fiber filter meshes really helps prevent blinding issues, which makes particle separation work better, particularly when dealing with tough industrial situations. Companies working on R&D have found out through testing that these composite designs cut down on material buildup problems that often mess up regular screening operations across different sectors. Field tests indicate that incorporating such composite materials typically reduces blinding incidents somewhere around 20 percent or so, which means operations run smoother day to day without constant maintenance headaches. For manufacturers in chemical processing plants or food production facilities where performance standards are high, this kind of enhancement matters a lot because it keeps their systems running consistently without unexpected downtime caused by clogged filters.

- Composite structures enhance anti-blinding capabilities.

- R&D confirms reduced material buildup.

- Field results show at least 20% reduction in blinding.