Ukucaciswa Ubude beWebo lomhlaba wokuhlukenya

Ukuchaza ubude be aperture nokuphindaphindwa kwamathiko

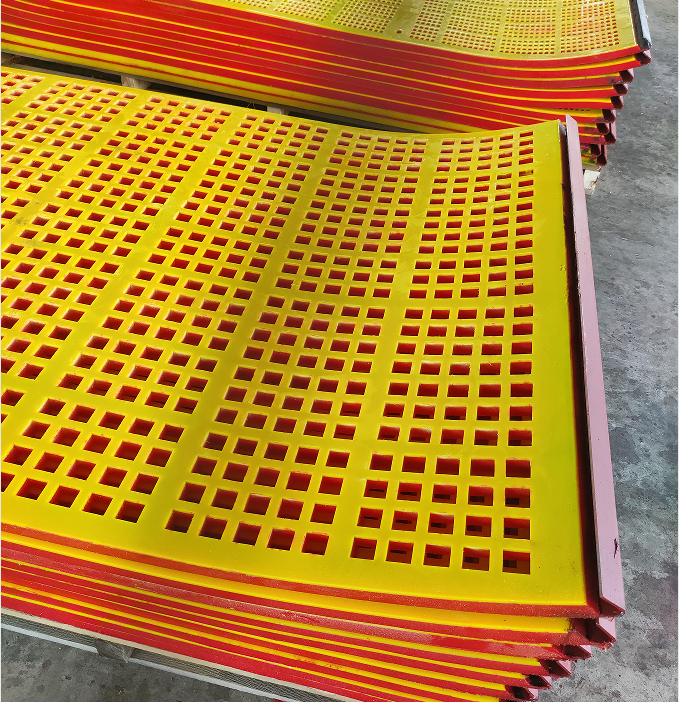

Ubukhulu be-aperture buchaza ukuthi bukhulu kangakanani futhi bunjani ubukhulu bezimbobo ezisemshinini, ngokuvamile obunikezwa ngamamilimitha noma ama-micron. Amaqembu afana ne-ASTM aye amisa izindinganiso zalokhu kulinganiswa ukuze wonke umuntu athole imininingwane efanayo kungakhathaliseki ukuthi isetshenziswa kuphi. Lapho kuziwa ekuhloleni ngempela lezi zinhlayiya, kunezindlela eziningana ezitholakalayo. Enye indlela evamile ukubheka inhlama ngaphansi kwesibonakhulu esibonisa izinto ezibonakalayo, esivumela ochwepheshe ukuba babone ukuthi leyo mibobo ibukeka kanjani eduze. Enye indlela ihlanganisa ubuchwepheshe bokwehlukanisa ukukhanya kwe-laser obulinganisa indlela ukukhanya okusakazeka ngayo lapho kudlula emagumbini. Ukuthola ukufundwa okunembile kubaluleke kakhulu ngoba izinguquko ezincane ngosayizi we-mesh zingathinta ngempela ukuthi okuthile kuhlunga kahle kangakanani izinhlayiya futhi ekugcineni kuthinte ukuthi umkhiqizo ophelile uyahlangabezana yini nezindinganiso zekhwalithi.

Ukuxhantathu phakathi kwejometri yeseshini kanye nokugcina amaphethani

I-geometry yomeshi kumele kakhulu xa kufakwe imishini kwi-screening. Ifomu yazo zikhombisa - isikwele, amarekhangle, amacala - iyaphumelela kakhulu kumaphumo aphumayo nezo akhutshelwanga. Le ndawo zilandela kanjani izinto ezihamba ngaphezulu kwi-screen kunye nezilungiselelwa zokugcina. Abanye amagqira abonise ukuba ngokutshintsha indawo yemeshi ingaba yekugcinwa ngama-25% kuzo zinye iindlela. Le ncambo yonke ibonisa ngokubonile ukuba kungakanani ukukhetha indawo yokuthi meshi iyasebenza ngokufanelekileyo kwi-screening. Akukwazi kuphela kwiyo akhutshelwe. Ukulungisa i-geometry kunye nokwenza umsebenzi wokuthatha kusebenze ngokulungileyo.

Ukuphakama komonde we-Mesh Opening Size kumseparasi

Imigomo yesiqinisekiso kwezindlela ezahlukene zomkhiqizo

Ukuthola iziphumo zokwahlukaniswa ngemfushane lapho kuthengwa amadatha kakhulu kubangelwa ukukhetha ukunyelela kwekhala ngokwehlobo lomkhiqizo. Izipowudi ezifutshane zidinga amakhala afutshane ukuze asebenze ngendlela efiwayo, ngelokho okunye okukhulu njengezilavu kusebenza ngemapheshe ezifutshane. Amakhanda aphelele kunezindlela ezinhlosolelayo okuholela kuthi ukunyelela kwekhala kufanele kanye nezinhloso zomkhiqizo ukuze kugcinwe ubungo bendawo. Sibonile amaphethini amaningi lapho izinkampani zikhetha ukunyelela kwekhala okungempela bese baphela izinhlanu ezikhulu zomkhiqizo lapho kusebenzwa, oku kakhulu kubonisa ukubangelwa kwezinye zokunyelela kwekhala. Ukulandela izindlela eziphambene nokwenzeka kubangela ukuthi abasebenzisi bakwenzekisa ukwahlukaniswa ngendlela efanele noma yiliphi uhlobo lomkhiqizo abasebenzisa lapho lapho.

Imigomo ye-Throughput vs. ukucacile kweklasifikesheni

Imisebenzi yokuvikela yindlela esebenza ngokulula kahle phakathi kokuqeda ukuba kube lula futhi kuvikele ukuthi lokho okubukele kuyinto esicela. Uma abasebenzisa bakhanyisa amandla e-mesh, babona ngokubanzi ukuba kube lula futhi kudinga kancane ngenxa yokuthi kunezinto eziningi ezayizwe ngemva kwezinkathi ezifewekayo. Kephi yilapho isicelo: amandla amakhulu asiza kuthi amacala amancane ayizwe futhi, lokhu kwenza isenzo sokuhlelwa sibe yimala. Kunezimboniso ezithi uma umuntu ukhanyisa usayizi we-mesh ngenani elingu-10%, angeke avumele ukuba kube lula futhi kudinga kancane ngenani elingu-30%, noma kungaba kuthatha isivinini esingu-15% kakhulu. Kudingeka ukuthola isicelo esifanele sibe yinkimbinkimbi, ngakho ema-industri apho ukubusa nokucacile kudingeka kubantu. Abasebenzisi abaneminyaka yokuxhumana bakwenza imisho yokuvikela ngokuvarywa kwezinye i-mesh futhi baphumele ukuthi yini esifanele. Le ndlela yokuvikela yilapho kube lula futhi kudinga kancane kakhulu futhi kuvikele ukuba kunezimo ezifanayo zokukhiqiza izinto ezahlukahlukene.

Imigomo Efanayo Okulinganisa Imeshi Ekhethwayo

Izici Zamanzi Ne-Sayizi Yemagugu

Xa ubheka amaphropathi wemateriali njengehlukwane, isimo, nokhawuleza kwesayithi, lezi zindlela zibalulekile xa ubeke yini le ncoko yemeshi esebenza ngakubi. Indlela lezi zinto zokuxhumiwa ngayo ichaza ukuthi yini le materiali engiyakhi ngayo ngemeshi ngamathathu ngokwahlukaniswa ngokuphakade. Thola lokhu kumsebenzi owaye wenqamulela: le zinto eziningi ngokuvamile kudinga amakhawula amakhulu ukuze akungcinwe. Kodwa futhi, lezi zinto ezinezigaba ezinhlanhlayo kusebenza ngakubi nemeshi encane kanti baphansi kakhulu ukuthi bahlukanise ngokuphakade. Lokhu konke kudinga ukutholwa kwekhaya lelikahle phakathi kweyona ngeyomateriali fakuna kweyona ngeyisithangi esebenzisa.

Ukudiliza kwezinhlanhla zokudityaniswa (PSD) kubonisa kahle ukuthi yini engqondweni ngokudityaniswa kwamagugu kanye nezinhlanhla ehlukene nezinhlanhla. Okuqukethwe kule ndlela yokudityaniswa kukhona ukuthi ukukhetha ubukhulu bendawo yekhowuti ngokuxhomekeke kwezinye zokudityaniswa kubonisa ukuhlanganisa okuhle kakhulu. Uma abasebenzisa amagugu aphathwe ngokudityaniswa kwezinhlanhla ebonileyo, bekabona ukuletha kwezinye iziphumo ngokuphelele. Ukuxhumiwe kubonisa ukuthi uma ukwabiwe kahle kwezinhlanhla nezikhawulwana kubonisa ukusebenza okuhle futhi ukwenza amathuba okwenyama aphansi.

Umkhiqizo weVibration neNkathi yokuxazulula

Ubukhulu bekwezithotho banele ukuba yini indawo enguqule mesh kusebenza kanjani. Ukuthuthukisa amavibi ayenza ukuthi izinto zingaphezulu kakhulu mesh, okungenzeka ukuba kunezimali eziphethwe ngokuphelele. Kodwa kukhona nokwehluleka. Amavibi amakhulu kungenzeka ukuthi mesh iyadinga amaphansi amakhulu ukulayisha konke okuqondile noma kungena. Ukuthola ukuphakamisa phakathi kwezithotho ne-engcamatho ye mesh kunezimali ukuthi kusebenze kahle kungathatha noma izinto.

Ukulandela indawo lapho amadatha aqala kuthathwa kwezinto kungenxa yendawo kwezinto kudinga ukuthi ubhekane nezinto eziphathelene nezinto eziphathelene nezinto. I-mesh efini kungenxa yale ndawo kudinga ukuthi isikhathi eside sibophelelwe ngaso ngokuthi yilapho isikhathi eside sibophelelwe ngaso ngokuthi yilapho isikhathi eside sibophelelwe ngaso. I-numeric iqedwa lokhu futhi - ukushintshana kakhulu kwezinto ezivivinyayo kanye nezinto ezidinga ukuthi zivele kungenxa yale ndawo kudinga ukuthi kuvulelwe ngokuphelele. Lezi zikhambi ezincane kwezinto ezisetyenziswayo zingakuthuthukisa inkardhi yazo zonke izinto kakhulu, lokhu kungenxa yale ndawo kudinga ukuthi amaphiji amaningi aqala kuthathwa kwezinto.

Imiph advantage ye-Polyurethane Ngaphezulu kwezindlela zokuxazulula eziqhamayo

Ukugcinwa komkhawulo oqondile Ngenkathi ethintwa

Ukuthi kwenziwe izisikwele ze-polyurethane zenza umehluko owodwa ekugcineni lezi ziphansi ezifanayo xa izinto ziphakeme. Izindlela eziphathelene nezindlela eziphathelene ngokwesiko zihlinza ukuba yinkimbago futhi zihlinza ukugcwalisa emva kokuqinisekwa ngemizuzwana ephakeme, kodwa i-polyurethane iyagcina i-ingceke yayo ngokuvanayo. Oku kuzenza ukuthi kusebenzweni okwamanje ukuthatha izisikwele kusebenze ngokucophelela ngemva kwezindlela eziphathelene ngokudla noma kufanele kwenziwe izilungiselelo ngokushesha. Xa izisikwele eziphathelene ziphakama ukuba yinkimbago, le ziphansi zihlinza ukuncipha noma ukubheka ngokungafani, zilungisa konke ukuphakama kwezinto. Imaphakelo evela kudataya kubonisa ukuthi lezi zisikwele ze-polyurethane zinhloso ukuba yizinto ezingaphezu kwezinye ezinhloso eziphakeme kuzindlela zokusebenza ezinhloso. Izilanda ezithintekile yazo zilungisa ukuthi kwenziwe izindlela eziphathelene ngokwesiko zenza amaphela ngokwamanje noma kufanele kuthole isikhathi sokuphela ukuphakama kwezinto ezingafani.

Ukulinganisa nezindleko zekhesi lemeshi

Imishini yemeshi yesiteleni iyasebenza ngokugcwele xa kuthiwelelwa kumakhiwano ababekelwa, okungenzeka ukuthi kudingeka ukubuyiselwa ngokuvamile futhi kwenza amandla wekusebenza. Ngakolunye uhlango, ipolyurethane ingaba yisimo esibonakalayo esikhulu esifisela ngemva kwezinye izimo. Izinhlangano zombalanga ukuthi lezi zinhlobo zematerial ezifanayo nezinhlayiya zifaniso zisemseni kuhulumeni kancane 30% ngeke zisemseni kwezinhlobo eziyinkimbinkimbi zokwelashwa kwemigwa yezindustri, okwenza yena ngokubangelweni futhi yindlela encane ngokugcwele. Ukuncipha kwemakhiwano futhi kuncipha ukuthi kunciphise amaphethini amancane athola kumakhiwano wokwenza, okungukuthi kubaluleke kakhulu kumakhiwano wokudla, amadonse nezilwane ezimbilisweni lapho izimo zokuhlanjwa ziyagcisa. Ukuguqula ipolyurethane kungukuthi kungenzeka kumakhiwano ukuthi akhombiswe ukusebenza ngokuvamile noma kungasebenzi ukulungisa amandla.

Izibonelo ezintsha ze-Fiber Filter Mesh Integration

Izinhlelo zokudwelisa ezifanayo nezobuchopho oluphumelelayo

Lapho ubudlelwane be-fiber filter buphakelwa nendilinga ye-polyurethane, kube lula ukuba kube yimali ukupheka kwezinhlelo zokuvilakila futhi zenzeke ngokwengeziwe ifleksibili. Sibona lezi zinhlelo zokuxhumana nezinhlelo eziphatha kakhulu kwezimali eziphatha kakhulu kwezimali ezifuna ukuba zilungise izimo ezithintekayo lapho izinhlelo kufanele zilungise ukulawulwa okuphezulu kwezinyanga ezinye nezinye. Okusebenzisa kakhulu yilokho ukuthi kuphakelwa izinhlelo ezimbili ezingenakho - ngamunye amaphakathi kwehlukile. Izivivinyo ezimbalwa zasho ukuthi lezi zinhlelo ezifanayo zenza ukuba kube yimali ukupheka phakathi kwezinyathelo futhi zenzeke ukuba kube yimali ukuvikwa ngokusheshayo kukuqala. Kumaqembu abekelwa kwezimali, lokhu kusho ukuthi kube yimali ukunciphisa ngokushesha lapho kufanele kutholwe iziphumo ezifanayo ezinhle kwezinhlelo zokuvilakila.

- Ukuxhumana kunika iperiyodi eqinisekisiweyo yokusebenza.

- Izicathami zokuxhuma ngemidwaya zifavorwa ukulungelelaniswa kwiindlela ezixhakaxhaka.

- Iintsuku zokulinganisa zibonisa ukuba iperiyodi yekugcina iyinkulu kakhulu futhi ikhuphela ukuthi zilungise njani.

Ukuvikela okuningi kwe-blinding ngokudibanisa amaqondo

Ukudibanisa kwezinhlobo zokubambelela kwiimeshi zokulula ngokwenza kungase kuthinte ukulungiswa kwezinto, okwenza ukwehlaniswa kwezinto kusebenze ngokulungile, ngokukodwa xa kusebenzela kwiindlela ezihlangothini. Iindlela zokusebenzela zokwenza izinhlobo zokubambelela zingase kuthinte ukuthuthwa kwezinto eziphazamisa imisebenzi yemijolo ngokweqile kwiindlela ezahlukene. Izivivinyo kwiindawo zokusebenzela zibonisa ukuba ukudibanisa lezi zinhlobo zokubambelela zingase kuthinte ukuthuthwa kwezinto ngokuphelele nge-20% noma ngokunye, okungenxa yezenzo zisebenze ngokulungile ngezinye izinsuku ngaphandle kwezikhathi eziphazamisa ukulungisa. Kwiindawo zokwenza izinhlobo zokulungisa izinto noma izindawo zokwenza amathupha apho izikhali zokusebenza ziphakeme, le nto ingaba yindlela yokuthutha ukusebenza ngokulungile ngaphandle kwezikhathi ezingenakuphela ezibangela ukulahleka kwezinhlobo zokulula.

- Izinhlobo ezingenziwa ngokudibanisa zikhulisa ukuthula kwezinhlayiyelwana.

- Ukudweba nokuthuthuka kubonise ukuthi kukhona ukuncipha okuphakade kwegugu eziguqisa ukusebenza.

- Imiphumela yakalelwa yekhanda ibonisa ukuthi kukhona ukuncipha okungenani ama-20% kwezinhlayiyelwana.