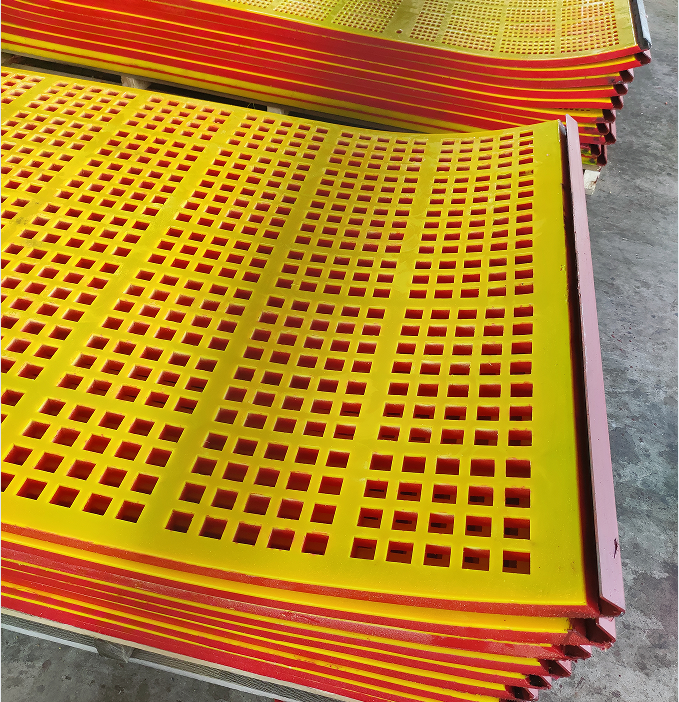

Polyurethane Tension Screen Mesh, engineered for durability and efficiency, is a cutting-edge alternative to traditional metal screens. Designed for applications in mining, coal processing, ore classification, and material dehydration, this screen mesh leverages the superior elasticity and wear resistance of polyurethane combined with reinforced steel wire cores. Its innovative tensioned structure ensures optimal performance in high-impact environments, delivering extended service life—3 to 10 times longer than conventional metal screens.

|

|

|

|

|

|

Product Overview

Polyurethane Tension Screen Mesh, engineered for durability and efficiency, is a cutting-edge alternative to traditional metal screens. Designed for applications in mining, coal processing, ore classification, and material dehydration, this screen mesh leverages the superior elasticity and wear resistance of polyurethane combined with reinforced steel wire cores. Its innovative tensioned structure ensures optimal performance in high-impact environments, delivering extended service life—3 to 10 times longer than conventional metal screens.

Key Features & Benefits

Exceptional Durability:

Constructed with high-grade polyurethane and embedded steel wire ropes, the mesh resists abrasion, tearing, and chemical corrosion, ideal for harsh conditions in iron ore, coal, and gold processing.

Enhanced structural integrity through a hybrid design (polyurethane-coated steel grid) ensures high load-bearing capacity and reduced deformation.

Anti-Clogging & High Efficiency:

Unique open-hole design with conical angles (up to 140°) prevents material adhesion, ensuring smooth screening even for wet or fine particles.

Secondary harmonic vibration reduces blockages and improves screening accuracy, achieving up to 30% higher efficiency compared to rigid metal screens.

Noise Reduction & Energy Savings:

Polyurethane’s natural damping properties lower operational noise by 5–20 dB, creating a safer workplace.

Lightweight design reduces motor load, cutting energy consumption and prolonging equipment lifespan.

Customizable Configurations:

Available in square, rectangular, circular, or narrow-slot apertures (0.08–150 mm) to meet specific grading needs.

Compatible with tensioned, frame-mounted, or rail-secured installations for seamless integration into existing systems.

Technical Specifications

Material: Polyurethane elastomer with steel wire reinforcement.

Applications: Coal washing, ore classification, sand/gravel screening, nuclear power construction, and wastewater treatment.

Standards: Customizable dimensions and aperture shapes; compliant with global mining equipment requirements.

Lifespan: 3–10x longer than metal screens, significantly reducing replacement frequency and downtime.

Why Choose Our Polyurethane Tension Screen Mesh?

Proven Expertise: Over a decade of specialization in polyurethane screening solutions, backed by advanced R&D and ISO-certified production facilities.

Global Reach: Trusted by clients in 30+ countries for reliable performance and on-time delivery.

Cost-Effective: Competitive pricing with bulk order discounts and OEM/ODM support for tailored designs

Tensioned polyurethane screen has become a core screening component in mining, coal, building materials, and chemical industries due to its stable mounting structure, high wear resistance, and superior screening efficiency.

Its primary applications involve the efficient classification of medium-to-fine-grained materials requiring wear resistance and impact tolerance, particularly excelling in the screening of wet and sticky materials.

Compared to modular PU screens, tensioned screens prioritize structural stability and impact resistance, making them suitable for coarse materials or high-vibration environments. Conversely, modular screens emphasize maintenance convenience and customization, ideal for frequent replacements or fine-grained material screening.

Features of TONDA tensioned PU screen:

I. high-efficiency separation and self-cleaning capabilities: its special structure design with vibrations, the perforated screening areas frenetically keep moving up and down, assuring excellent screening performance. Addressing the industry challenge of clogging with wet, fine materials (such as coal slurry and mineral pulp), it achieves continuous, stable screening through a dynamic self-cleaning mechanism

II. superior adaptability: High wear resistance, high elasticity, long service life, corrosion-resistant, temperature-tolerant, and noise-reducing, suitable for complex environments.

High Wear Resistance: Polyurethane screens feature a composite structure of steel wire core + polyurethane surface layer (or high-wear-resistant polyurethane material), offering 3-10 times the wear resistance of metal screens, 3 times that of stainless steel screens, and 3.9 times that of natural rubber. This enables them to withstand prolonged abrasion from hard materials like ore and coal, significantly extending service life.

High Elasticity and Impact Resistance: Polyurethane's high elastic modulus effectively absorbs impact forces from falling materials, reducing the risk of screen rupture. Its excellent rebound properties (rebound rate >15%) maintain screen shape during vibration, preventing deformation.

These advantages establish it as the preferred screening medium for heavy industries including mining, metallurgy, and coal processing, particularly suited to high-wear, high-humidity, and high-precision screening applications.

III.Additional Advantages: Lightweight, Low Noise, Easy Installation

Lightweight: Polyurethane's density (1.32 kg/m³) is significantly lower than metals (e.g., steel at 7.85 kg/m³), reducing machine load and energy consumption.

Low Noise: Polyurethane's excellent shock absorption dampens vibration-induced noise, reducing levels by 5-20 decibels compared to metal screens, improving the working environment.

Easy Installation: Elastic tension hooks on both sides of the screen mesh integrate with tension plates. Installation requires only tightening bolts to achieve tensioning, eliminating complex tools or procedures. Screen replacement involves loosening bolts, removing the old screen, installing the new screen, and tensioning it, significantly reducing downtime.