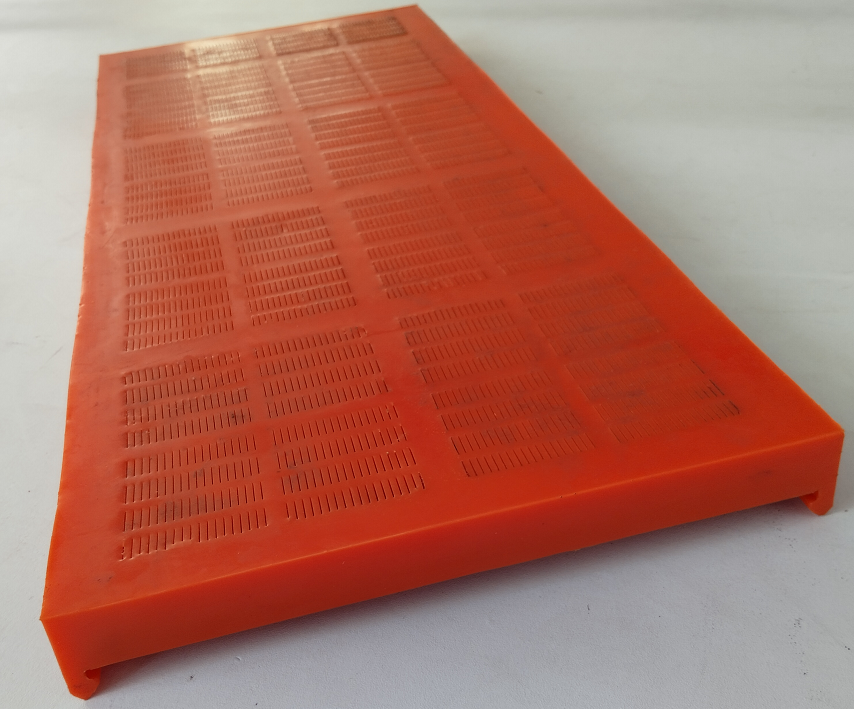

Ukuthi I-Polyurethane Screen Mesh Inzima Yenkululeko Yezimali Zokusebenza

Ukudampina Kwemikhono Ne-Reduced Vibration Load kwezinkambo Zokuscreena

Yini okwenza i-polyurethane ibe yinkulu kakhulu? Ukuziphatha kwakhe okwenzelwa ngokuzenzakalelayo kuyasebenza njengomshini wokuvimbisa ngaphakathi. Hlola umeshi wesitili — luyathumela kuphela amavibrations ngqo ngaphandle kokudampina kancane. Kodwa i-polyurethane iyavimbisa lezi zivibrations ngalolwandle lwamahlelo, okusho ukuthi kungaba ne-40% yamavibrations angathumelwa futhi. Ngokulandela umlando omtsha wezindlela zokubhekana nokuphila kwezinkambo kusukela eminyakeni yase-2023, lokhu kukhona ukudampina kuyasula isibopho esikhulu kwezivibrating screens. Futhi, ubani akakwazi ukubona? Ukufa kwamabheiringu kushintsha ngemva kwe-30% futhi. Uma izimboni azizwa ngamakhono amabi kakhulu, abasebenzi bafaka izinto zabo ezincane kakhulu nangamaphepha angaphezu kwezinye. Lokhu kubusa iziphumo eziningi emva kwalokho, kusula izimali zokusebenza kuzo zonke izindlela — kuzo zonke izindlela zokufakwa kanye nesikhathi sokusebenza ngokuzenzakalelayo.

Ukunciphisa Kwamperaji We-Motor Ngokusebenzisa Ukuchaza Kwezimali Ngokuhle

Izihlangozeko zesikhumba se-polyurethane zinamathuba okukhula kwezinye izinhlobo zokugcina amasonto ngokuphelele, nokuthi zinamaphuzu amahle aqondile ukuthi abeke isibonelo sokubambisana kwamasonto futhi zilahlele lo mlando wokubuyela kwamasonto—lobudlelwano lapho amasonto amanengi amafanayo ayabuyela kusukela kusukela kuqondile ukuze aphume. Uma amasonto ayakhula ngendlela efanele njalo, lokhu kunciphisa umsebenzi owenzelwa ngamotora. Amagumbi amaningi e-industri ayabona ukuthi izimitha zabo zokusebenza zazincipha phakathi kwe-15 ne-30% uma bavula kusukela kwezihlangozeko zezihlangu zezinkampani zokuziphatha ngokwesikhathi esedlule, ngokwesifundo esishicilelwe ku-Industrial Processing Journal ngo-2023. Lokhu kuchaza ukuthi kunciphwa ngaphezu kwe-18 ku-22 kilowatt-hours ngalunye iton yamasonto atholakala ngalunye isikhundla sokwenza izinto.

| Isivumelwano Sokuhlelwa | Isikrini se-polyurethane | Igumba le-Gunyana |

|---|---|---|

| Ukuguqulwa Kwegama Lomotora | 25–30 kW | 32–38 kW |

| Ukuthumela Kwemithwalo | Nzima (Kwakhiwe Ukuthinteka) | Phezulu (Ngqo) |

| Umba Wokubuyisela Ukubhalwa | 35% ngezansi | Isigaba Esikhulu |

Lezi zizindlela zokuthuthukisa zihlanganiswa: indaba yebhizinisi yokuqondisa kwisikhathi sika-2023 yasibonisa ukuthi kusakho ukuthuthukisa kwamandla ngemali engaphezulu kwe-$740k ngalendawo ngomnyaka emva kokuguqula ku-isekreen zepolyurethane—ngokubuyiselwa okungaphezulu kwezinsuku eziyishumi nebane. Ukuncipha kwesikhathi sokusebenza kwemotolo kusha kuzisa isikhathi sokusebenza kwamakheshini futhi kunciphisa ingizo yokuhlula kwezilwane, kubhekisela kwezinkimbinkimbi zokusebenza ngokuphelele.

Ukusebenza Kwesikhombisa Sekreen Sepolyurethane Sokuvikela Ukungafihliwa Kusobala Ukuthuthukisa

Ukubuyiselwa Kwesikhathi Sokuhlelwa Nokusebenza Kwesikhombisa Ngokwesikhathi Sokusebenza

Yini okwenza i-polyurethane ibe yinkimbinkimbi kakhulu? Isitruktcha yayo yesipolimha esisikhangela kuyisebenza ngokuthi isubuka emuva kokuthi izinto zihlaziywa kuyo, ishwelela futhi isubuke emuva ngokushesha ukuze isondle isithunzi same sizinye sokufakwa emaphakathini. Lokhu kucleanwa ngokuzenzakaleyo kusivumela ukuthi le mphakathi libe libonakalile ngaphandle kokuthi kufuneka kuchazwe ngohand, noma kubhalwe ngomoya ophakamile. Uma sibheka imilayezo eyisidlo njengezindawo zokusebenza kwezinkambo, izinombolo zizichaza: kunezinkinga ezingu-40 percent ezingaphansi kumaqondiso wokuthi izinto zihlaziywa kungahleli kumaqondiso amadala asebenzayo. Kumaqondiso owasebenza ngokuphambili, lokhu kuthabatha ukuthi bafuna ukuthi bapheke ngokuphelele ngaphandle kokuthi bafuna ukuthi baphinde baphindele kusukela kubona ukuthi kunezinkinga zokuhlanza ngokuphelele, nokuthi kunezinkinga zokuhlanza ngokuphelele ngaphandle kokuthi kubonekwe ukuthi kunezinkinga zokuhlanza ngokuphelele.

Ukuphanta Ukuphuma Kwemisebenzi Nokuphinda Kuhlanza — Ukuthinta Ngokuzenzakaleyo

Kodwa kunezinkinga ezincane, izilwane zizokwazi ukuziphatha ngokungafanele kancane. Ukusuka futhi emachini emva kwezikhathi zokuphuma kungabangela ukuthi izimpahla ziyadinga amandla angaphezu kweminyaka yezinkulungwane-15 kuze kube yezinkulungwane-30 ngokusho kwe-‘Vibration Analysis Quarterly’ ngo-2023. Isikrini sesiphothi sase-polyurethane sithintela ukuthi isikrini singasolwa kancane futhi sibuyisa ukukhathazeka kokucima okubalulekile ekufakweni kwemachini ngaphandle kwesikhathi. Lokhu kusho ukuthi imotora ayisebenzi kancane ngokuphelele futhi ithintela ukuthi amandla amakhulu asukwe emva kokusuka kwemachini. Lokhu wonke kuchaza ntoni? Abasebenzi bokuhlinza abayikwazi ukusebenza kancane noma kancane, okususa imali kubani ubudlelwano nobugcina bezinto ezingafanele. Ngaphezu kwalokho, kunezimandla ezingafanele kuncane kuzo zonke izinhlanganiselo zokuproducwa. Izilwane ezisebenzisa lokhu isiphothi zizobona ukuthi kunezimandla ezingafanele kuncane ngokuphelele ngokuphelele ngokuphakanyiswa kwezinkulungwane-18 ngamandla okuprosesa ikhulu elinye ngokulingana nokusetshenziswa kwezindaba zokuziphatha ngokujwayelekile. Futhi masingakhohlwa ukuthi kunezinhlobo zokubona kanye. Lokhu isiphothi siyasebenza ngokuphelele ngokuphakanyiswa kwezinkulungwane-3 kulokho isiphothi sesihlangu se-wire esijwayelekile, ngakho abasebenzi bakhelwa kuncane kakhulu ngokuphelele kuzo zonke izinhlanganiselo zokwenza, ukuthumela, nokufaka kuzo izilwane zabo.

I-Polyurethane ne-Wire Mesh: Ukubala Iziphakade Zokusebenza Kwezinkululeko Zokusebenza Kwamandla

Ukusebenza Kwamandla Kwesikrini Esishaya: Amaphaneli Ama-PU Ayidinga Amandla Ongu-15–30% Okungafanele

I-mesh yebhodi yepolyurethane iyabhekisa imithwalo yezimali kakhulu ngokulingana ne-mesh yamathambo ethuluzi lapho isetshenziswa emasikeni athambekayo. Izimboni zemvelo zibonisa ukuthi kusethwe amandla angaphezu kwe-15% kuze kube ngu-30% ngaphansi kwezinye izikhathi kodwa kufanele kwenziwe umsebenzi othile. Kunezizindlela ezimbili zokuthi lokhu kuyakha. Okokuqala, iziphumo zokubheka kwesithunzi semateriali sikhuthaza ukuthambeka kabusha phambi kokufika kwezinqakamba ezingcono njengezibhodi nezinkampani zokuthambeka. Okwesibili, i-mesh iyabuza ubumbane bakhe kangako futhi ngakho amathuba ayaseparatha kahle kusuka kusuka kumugqa wakhe. Lokhu kungavimba izimo apho izisistimu zemesh yamathambo ziyadlula ukusebenza futhi ziyadlula ukuthola amandla ne-torque. Imesh yamathambo iyadlula ngokuphela kanye iyadlula ukubuza ubumbane bakhe, kodwa i-polyurethane iyadlula ngaphandle kokudlula ukubuza ubumbane bakhe noma kufakwa amandla. Amotori ngakho ayasebenza ngamandla angaphezu kwe-amperage angaphansi ngaphandle kokukhupha umsebenzi wokuproducwa. Yenza isibonelo sesikhulu sezindustria zokuprosesa izinto ezinomthwalo esebenza ngamandla angaphezu kwe-500kW ngaso sonke isonto ngonyaka wonke. Kungabhekisa ngaphezu kwe-$18,000 ngonyaka ngamandla yomkhakha ngalokho kuphela. Lokhu kubhekisa ukuthi kuyakha umphumela omuhle kwezindustria apho izimali zomkhakha ziyagcina umgcinwa wokuphatha nokubhekisa kwezinkinga zomhlaba ziyagcina ukuthi ziyisisekelo sokuthi ziyakha umphumela omuhle kuleli xesha.

Ukuchaza Kwezimali Zokusebenza Kwesikhathi Sokuphila: Ukuphelela Kwemithombo Yokuqinisa Nezinkundla Zokuziphatha Kwe-PU Screen Mesh

Ukuqinisa Kwamandla, Ukukhathazeka Kwemithombo Yokuqinisa, Nokuphela Kwezimali Zokusebenza Kufika Kukuguqula Kwamandla Okugcina

Ukugcina kwezindlela zokusebenza zokubhala kanye nokuthabatha kahle ukungena kwemithombo kusiza ukuthi ipolyurethane ibe yinkimbinkimbi yokubhala ngokuphelele ngaphandle kokukhupha isakhiwo lalo noma isakhiwo. Lokhu kusiza ukuthi ubuso bakho bube phakade kusukela ku-3 ku-5 amaphuzu kunezindlela zokusebenza zokubhala zokuziphatha ngokujulile. Uma sikhupha ukuchaza kabusha, siyakhupha lezindlela zokusebenza zokufaka amandla. Ukwenza izipaneli kuphela kusisa phakade kusukela ku-15 ku-25 kilowatt hours ngameteru omphakathi, ngaphandle kokuthi kunezindlela eziningi zokuthumela futhi zokufaka. Ukuchaza okungafanele kusiza ukuthi kubhekwe phambi kokuthi kusakheke ukusebenza kanye. Ngasinye isikhathi esikhuluma ngokuvutha izinto zokusebenza emva kokuthi kusakheke, kuyabhalisa amandla angaphezu kwe-15 ku-30 percent kunezindlela zokusebenza zokujulile. Ngakho-ke ukunciphisa lezi zikhuluma zokuvutha kusiza ukuthi kubhaliswe amandla ngokuphelele. Uma sibheka umlando wakhe oyingaki, isakhiwo sokubhala kusiza ukuthi kunciphiswe ukusebenzisa amandla okuchaza kabusha ngokuphelele kusukela ku-18 ku-32 percent ngonyaka ngaphandle kwezindlela zokusebenza zokubhala zokuziphatha. Kusiza futhi ukuthi kubhekwe phambi kokuthi kungenwa inkulu yezinto ezingavunyelwanga, okusiza amakompani ukuthi baphinde kumaqondiso abo abazimele.

Imibuzo Evame Ukubuzwa

Kungani i-polyurethane ithintela ukuthintela kahle kune-mesh yezinkolo?

Ukuhambisana kwakhe kwezinkolo kusiza ekuthintheleni ukuthintela emazini, okuthintela ukuthintela okufika ku-40% kunezinkolo, okuzokuthintela kuphela ukuthintela.

I-polyurethane screen mesh isenza njani ukuthintela amandla?

I-polyurethane screen mesh isenza ukuthintela amandla ngokuthintela ukuthintela kwe-motor, ukuphatha kahle kokuthintela kwezinto, nokuthintela ukuthintela kwezinto, okuthintela ukuthintela kwezinto ngokuqondile nge-15-30%.

Izifiso zokusebenza kwezinsuku eziningi zokusebenzisa i-polyurethane ngaphezu kwe-wire mesh ziyini?

Izifiso zokusebenza kwezinsuku eziningi zivame ukubhekana nokuphila kwezinsuku eziningi, ukuthintela ukuthintela kwezinsuku eziningi, ukuthintela ukuthintela kwezinsuku eziningi kwezinkolo nokuthintela kwezinsuku eziningi, nokuthintela ukuthintela kwezinsuku eziningi ngokuthintela kwezinsuku eziningi.

Kwenzani izindawo ezithintela i-polyurethane screen mesh?

I-sieve mesh yama-polyurethane iyasebenza kakhulu emizulwini eyisilisa njengezindawo zokuprosesa izinkhuni, apho iyabhindela ukugcina nokuhlinza ukusebenza kwemithombo.

Uhlu Lwezinto Eziqukethwe

- Ukuthi I-Polyurethane Screen Mesh Inzima Yenkululeko Yezimali Zokusebenza

- Ukusebenza Kwesikhombisa Sekreen Sepolyurethane Sokuvikela Ukungafihliwa Kusobala Ukuthuthukisa

- I-Polyurethane ne-Wire Mesh: Ukubala Iziphakade Zokusebenza Kwezinkululeko Zokusebenza Kwamandla

- Ukuchaza Kwezimali Zokusebenza Kwesikhathi Sokuphila: Ukuphelela Kwemithombo Yokuqinisa Nezinkundla Zokuziphatha Kwe-PU Screen Mesh

- Imibuzo Evame Ukubuzwa