How Terrain Type Dictates Snow Plow Blade Performance

Asphalt, Concrete, and Parking Garages: Prioritizing Surface Protection

Asphalt, concrete, and those parking garage floors need special attention when it comes to blade selection because nobody wants expensive gouges or scratches ruining the surface. Rubber or polyurethane edges work wonders for these jobs. They bend and flex when they hit the ground, so they don't damage pavement but still get rid of snow pretty well. Another big plus? These materials cut down on noise during operation, which matters a lot in neighborhoods or inside buildings where loud machinery just doesn't fit. Compared to stiff steel blades, the softer options actually follow the bumps and cracks in surfaces better, reducing chances of knocking loose bits of gravel or making new potholes. Most maintenance crews know this stuff by heart since fixing damaged surfaces in busy spots can run upwards of seven hundred forty thousand dollars each year according to recent infrastructure studies.

Granite, Cobblestone, and Bridge Decks: Managing Abrasion and Impact Resistance

Granite block roads, old cobblestone paths, and bridge decks all create their own special problems when it comes to abrasion. Steel blades work well against those pesky stones sticking out or expansion joints, but they need trip mechanisms if we don't want to scratch up the surfaces. When dealing with historic areas that require extra care, reinforced polyurethane is often the go to solution. It stands up to wear and tear yet still cushions impacts enough to protect delicate surfaces. What really matters here? The material needs to last, edges should flex somewhat, and operators must control how much pressure gets applied. Too heavy handed and the beautiful stonework starts showing signs of wear much faster than anyone wants. People working these sites constantly walk a fine line between getting things cleaned efficiently and following strict preservation rules for those valuable heritage locations.

Snow Plow Blade Materials Compared by Terrain Demand

Steel Blades for High-Traffic Municipal Roads and DOT Highways

Steel blades on snow plows stand up to rough treatment on city streets and state highways that get pounded all winter long. These tough blades take hits from curbs, rocks, and packed snow without losing their edge or effectiveness. The special high carbon steel mix can handle over ten thousand cars passing by each year before showing signs of wear, which means these blades last about 40 percent longer than cheaper alternatives. For departments running plows nonstop during blizzards, this matters a lot. Surface damage isn't as big a concern when what counts most is getting roads cleared fast. Plus, the aggressive scraping action actually clears away dangerous black ice better than salt sometimes does, cutting down on chemical usage across many municipalities.

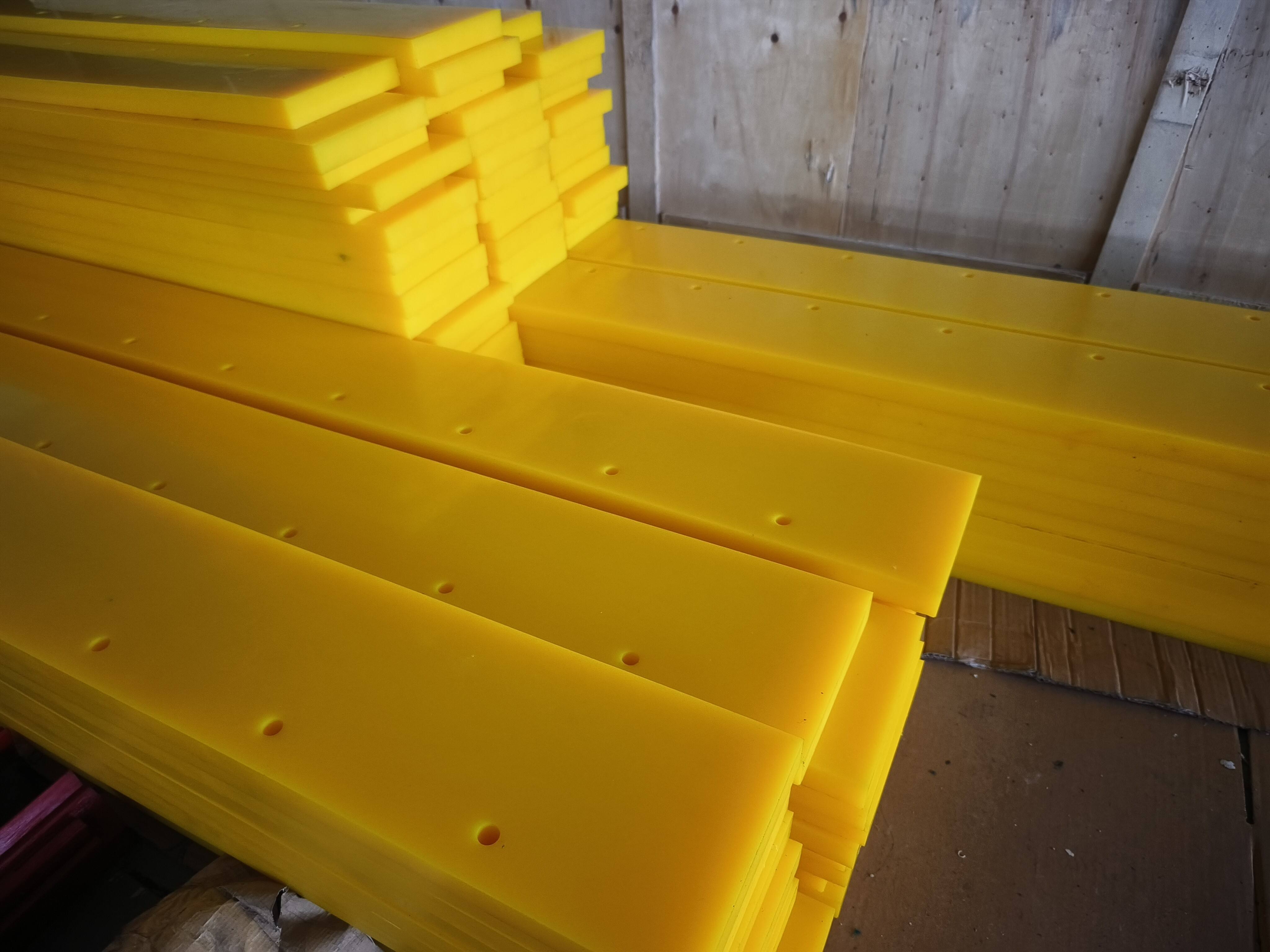

Polyurethane and Rubber-Carbide Blades for Sensitive or Uneven Surfaces

When working on sensitive surfaces such as brick walkways, ornamental stone work, or bumpy parking areas, using flexible polyurethane and rubber carbide blades helps avoid expensive repairs down the road. The shock absorbing nature of these materials lets the cutting edge follow the contours of rough spots without losing contact with the ground surface. According to some recent research in infrastructure care, polyurethane blades wear away at granite surfaces about 70 percent slower compared to traditional steel options. And those rubber carbide combinations? They cut down on street noise by around 15 decibels in city settings too. What makes all this matter? These special blades bend around things like storm drain covers and elevated manholes instead of gouging into them. That's why many historic neighborhoods and apartment communities specify these materials for their maintenance crews. Preserving the look of old brickwork and preventing damage to carefully restored paving stones just becomes part of regular operations.

Critical Design Features That Improve Terrain Adaptability

Adjustable Attack Angle and Down Pressure for Variable Grades and Contours

Blade control precision makes all the difference when dealing with hills and rough terrain during snow removal operations. Most modern plows feature adjustable attack angles ranging from 15 degrees to 70 degrees, allowing operators to set the right pitch depending on what they're facing. Steeper settings work better for packed snow on inclines, whereas flatter angles are ideal for level ground. The down pressure system comes into play here too, applying between 200 and 500 pounds of extra force so the blade stays in contact without damaging pavement surfaces. Cities have noticed around 40 percent reduction in required passes on those tricky hilly neighborhoods when operators tweak both these settings while actually working. Getting this right stops snow from rolling back uphill on slopes and protects delicate surfaces such as brick walkways or decorative concrete patios that would otherwise get scratched up by standard plowing methods.

Trip Mechanism Types: Bottom-Trip vs. Full-Trip for Rocky or Urban Infrastructure

The way blades respond to things they can't move through depends entirely on their trip mechanisms, which matters a lot when working around rocky terrain or navigating tight spaces in cities packed with infrastructure. Bottom trip systems that use springs mainly guard the bottom part of the blade. These work best on gravel roads or country paths where small stones pop up occasionally. Full trip systems, whether hydraulic or pneumatic, actually disconnect the whole blade when something gets in the way. This prevents those frustrating curb damages we see so often in parking garages and on bridges. According to field reports from equipment operators, these full trip setups cut down maintenance expenses by roughly two thirds when machines are running close to fire hydrants, storm drains, or cracked pavement sections. Some newer models tackle varied environments by combining both approaches into one system that automatically resets itself after an obstacle is cleared.

Application-Driven Snow Plow Blade Selection Guide

Picking out the right snow plow blade means matching materials and design elements to what kind of ground we're dealing with. Steel blades work best for those tough jobs on city streets and state highways where there's constant wear and tear from salt and gravel. They hold up way better under rough conditions than other options. But when working around delicate areas like asphalt parking structures or old fashioned cobblestone streets, something softer makes more sense. Polyurethane or rubber carbide blades won't scratch these surfaces while still getting the job done properly. Before making any purchase decisions, take time to look at several key aspects including how much pressure will be applied during operation, the type of surface being cleared, and maintenance requirements over time.

- Surface hardness and vulnerability to damage

- Frequency of obstacles (curbs, manhole covers, uneven pavers)

- Typical snow density and ice formation patterns

Operators should prioritize adjustable attack angles for sloped terrain and select trip mechanisms based on obstacle densityâbottom-trip systems for low-risk urban infrastructure versus full-trip designs for rocky or high-value surfaces. This terrain-focused approach minimizes equipment stress while reducing pavement wear by up to 40% compared to mismatched configurations.

FAQ

What are the best materials for snow plow blades on urban streets?

Steel blades are ideal for urban streets due to their durability in high-traffic areas and ability to handle harsh conditions.

How do rubber and polyurethane blades benefit sensitive surfaces?

Rubber and polyurethane blades are softer and can flex upon impact, providing effective snow removal while minimizing damage to delicate surfaces.

What is the purpose of adjustable attack angles in snow plows?

Adjustable attack angles allow operators to tailor the blade's pitch for optimal performance on varying terrain, such as hills and flat surfaces.

How do trip mechanisms work on snow plow blades?

Trip mechanisms help blades navigate obstacles; bottom-trip systems work for gravel roads, while full-trip systems are best for urban infrastructure to avoid damage.