Why Polyurethane Scrapers Outperform Alternatives in Hard-to-Reach Areas

Low-friction flexibility and conformability for consistent pressure on curved, narrow, or recessed surfaces

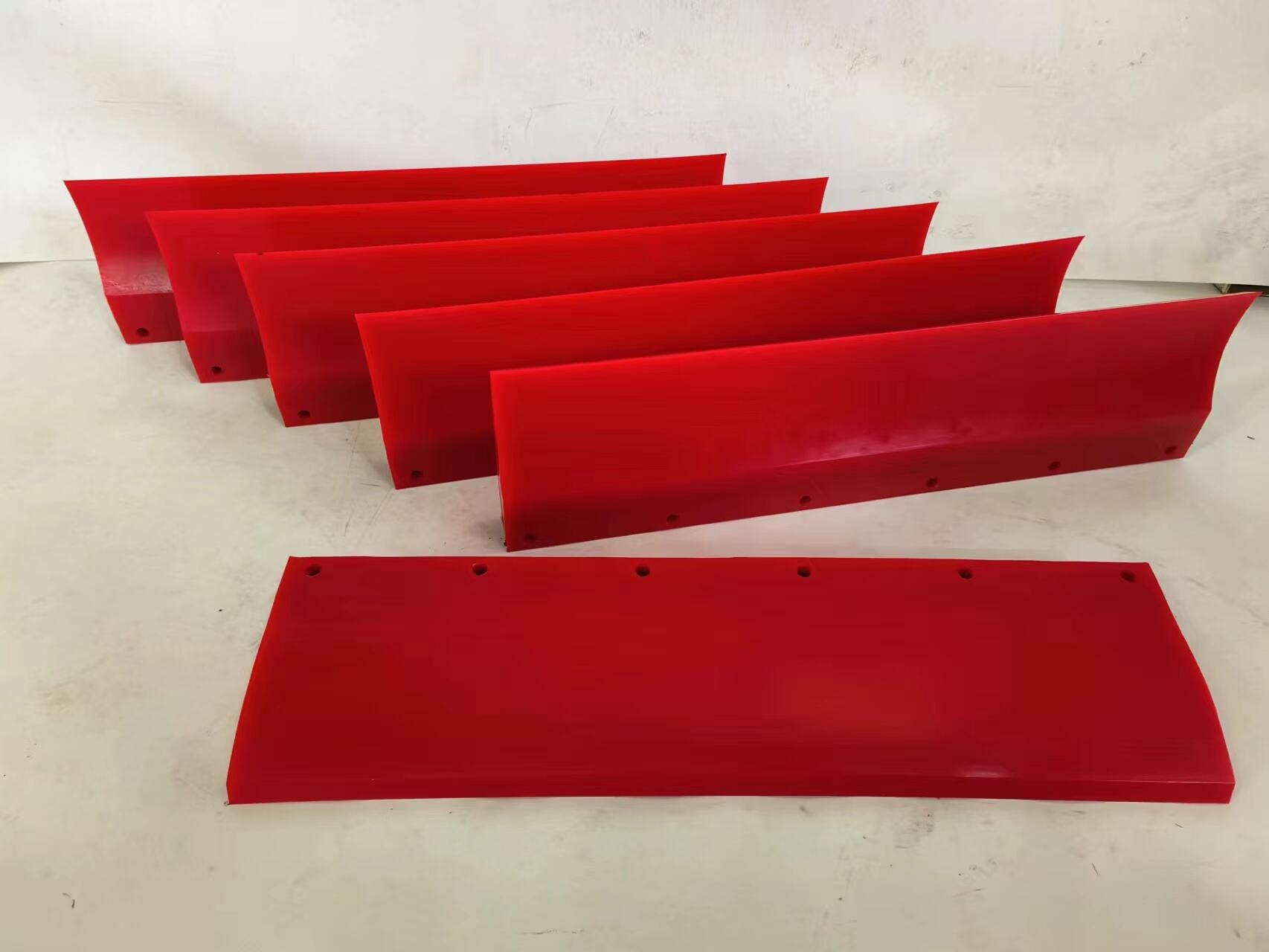

When dealing with rough terrain, polyurethane scrapers stay in consistent contact with surfaces that would trip up standard rigid options. These specially designed blades flex just enough to follow the contours of conveyor belts without harming delicate splices or wearing down the surface itself. This kind of steady pressure works wonders in those tough environments like mines and recycling centers, where stuff tends to pile up on belts causing all sorts of alignment problems and expensive downtime. Take Silver Peak's copper mine for instance they switched over to these polyurethane blades last year and saw amazing results. Carryback dropped from around 15 pounds down to barely over a pound per foot, plus their belts lasted almost twice as long between replacements. Another big plus? The material doesn't stick to things the way rubber does. Rubber blades need way more force to press against surfaces, which actually creates more wear over time.

Precision edge geometry and controlled durometer options enabling access to tight clearances

Manufacturers tailor polyurethane scrapers to micro-clearance challenges through three key design levers:

- Variable durometer selection (55A–90A Shore) to balance flexibility and structural integrity

- Beveled or chisel-edge profiles, optimized for specific gap geometries

- Thin-section designs, fitting spaces under 5 mm

The level of precision makes it possible to clean those tough spots like belt edge seals, pulley grooves that get clogged with slurry, and the corners of transfer chutes. These are exactly the kinds of areas where material tends to build up and cause all sorts of problems for operations. When blades are properly matched to the space available, most facilities report getting rid of around 90% of the leftover material from these problem spots. Standard steel or rubber options just can't match this kind of effectiveness, which is why so many plants have switched to these specialized solutions instead.

Durability and Long-Term Performance of Polyurethane Scraper Blades

Abrasion resistance in high-load, abrasive environments: ISO 4649 test data vs. rubber and steel

Polyurethane scrapers deliver exceptional wear resistance in demanding applications like mining and cement production, where abrasive materials rapidly degrade conventional blades. Independent testing confirms polyurethane withstands abrasive wear 74% longer than natural rubber under equivalent loads (Industrial Materials Journal, 2023). ISO 4649 abrasion testing further validates this advantage:

| Material | Abrasion Resistance | Temperature Range | Chemical Stability |

|---|---|---|---|

| Polyurethane | 9/10 | -40°F to 175°F (-40°C to 80°C) | 8/10 |

| Steel | 7/10 | Stable | 6/10 |

| Natural Rubber | 5/10 | 32°F to 140°F (0°C to 60°C) | 3/10 |

Field studies show polyurethane blades sustain over 14,500 operational hours—more than double the lifespan of metal alternatives—while maintaining elastic rebound that preserves consistent contact pressure without compromising surface integrity.

Resistance to cutting, tearing, and chemical degradation—critical for food, mining, and recycling applications

Beyond abrasion, polyurethane excels where mechanical impact and chemical exposure challenge other materials. In high-throughput recycling plants processing 1,200 tons daily, polyurethane blades retain 92% of original thickness despite repeated impact from glass shards and metal fragments. They resist ozone cracking, microbial degradation, and exposure to aggressive agents including:

- Strong acids and alkalis found in mining slurry

- Food-grade sanitizers and caustic cleaners

- Hydraulic oils and industrial solvents

NSF/3-A compliant formulations meet stringent food-processing requirements, eliminating contamination risks while remaining fully compatible with common belt-cleaning agents. As a result, replacement intervals extend to 12–18 months—four times longer than rubber equivalents in comparable settings—significantly reducing maintenance labor and total cost of ownership.

Optimizing Belt Cleaning Systems with Polyurethane Scrapers

Strategic placement: primary, secondary, and tertiary scraper stages using polyurethane for staged material removal

Getting conveyor belts clean effectively requires multiple stages working together. The first line of defense consists of polyurethane scrapers right after the head pulley area. These take care of around 90 percent of loose material through just the right amount of pressure applied against the belt surface. Then come secondary scrapers placed further down the belt run. They have sharper angles and tougher blades rated between 90A and 95A on the Shore scale, which helps knock out those stubborn bits stuck in belt grooves and textured surfaces. For really tricky spots, tertiary scrapers handle the final cleanup close to the tail pulley section or wherever geometry gets complicated. What makes polyurethane work so well is how it balances firmness with flexibility. This lets it adapt to normal belt movement and small surface bumps without needing constant adjustments. Plants that switch to this layered system tend to see about 30% fewer belt replacements over time and cut down unexpected stoppages by roughly 40% compared to setups with just one scraper unit.

Hybrid integration with FDA-compliant brushes for full-spectrum cleaning (pre-stripping + micro-residue removal)

When polyurethane scrapers work together with rotating brushes that meet FDA requirements, they form an effective cleaning setup for industrial applications. The main scrapers handle the heavy lifting first, knocking off most of the bulk material before it gets stuck. Then come the downstream brush units with their special filaments that don't shed particles, which tackle those tiny bits of residue hiding in the nooks and crannies of conveyor belts. This two-pronged approach grabs everything from big chunks down to microscopic particles that regular scrapers just can't catch. Food processors especially benefit from this combo since it keeps their equipment spotless according to health regulations while getting rid of almost all leftover materials on different types of belts. Facilities dealing with aggregates report seeing better than 98% less material sticking around after switching to this mixed system. As for maintenance, there's a smart schedule in place too. Technicians usually replace the secondary brushes right when the primary polyurethane scrapers start showing signs of wear. This timing trick actually extends belt lifespan significantly, sometimes adding 2 or even 3 extra years of service in tough environments like mineral processing plants where wear and tear happens fast.

FAQ

What makes polyurethane scrapers more effective in hard-to-reach areas?

Polyurethane scrapers offer low-friction flexibility and conformability, which allows them to consistently apply pressure on curved, narrow, or recessed surfaces where standard rigid options fail.

Why do companies prefer polyurethane scrapers for smoothing operations?

Polyurethane scrapers provide precision edge geometry and controlled durometer options, enabling effective cleaning and access to tight clearances where standard steel or rubber options fall short.

How do polyurethane scrapers compare with other materials in terms of durability?

Polyurethane scrapers exhibit superior abrasion resistance and long-term performance compared to natural rubber and steel, especially in high-load and abrasive environments.

What are the benefits of using polyurethane scrapers in belt cleaning systems?

Polyurethane scrapers allow for effective staged material removal in belt cleaning systems, offering reduced belt replacements and fewer unexpected stoppages.

Table of Contents

- Why Polyurethane Scrapers Outperform Alternatives in Hard-to-Reach Areas

- Durability and Long-Term Performance of Polyurethane Scraper Blades

- Optimizing Belt Cleaning Systems with Polyurethane Scrapers

-

FAQ

- What makes polyurethane scrapers more effective in hard-to-reach areas?

- Why do companies prefer polyurethane scrapers for smoothing operations?

- How do polyurethane scrapers compare with other materials in terms of durability?

- What are the benefits of using polyurethane scrapers in belt cleaning systems?