Ukuthi Isikrini Sokufilipha-Filipha Esishintshayo Sifika Kanjani Ekukhokhelweni Ngokwesibonelo Ngokushintsha Kwemvelo Yokushaya

Ubunzima Bekukhokhelwa Kwisikrini: Ubungakanani Bekwe-PU Mesh Nokuvuleka Kwemvelo Yokushaya

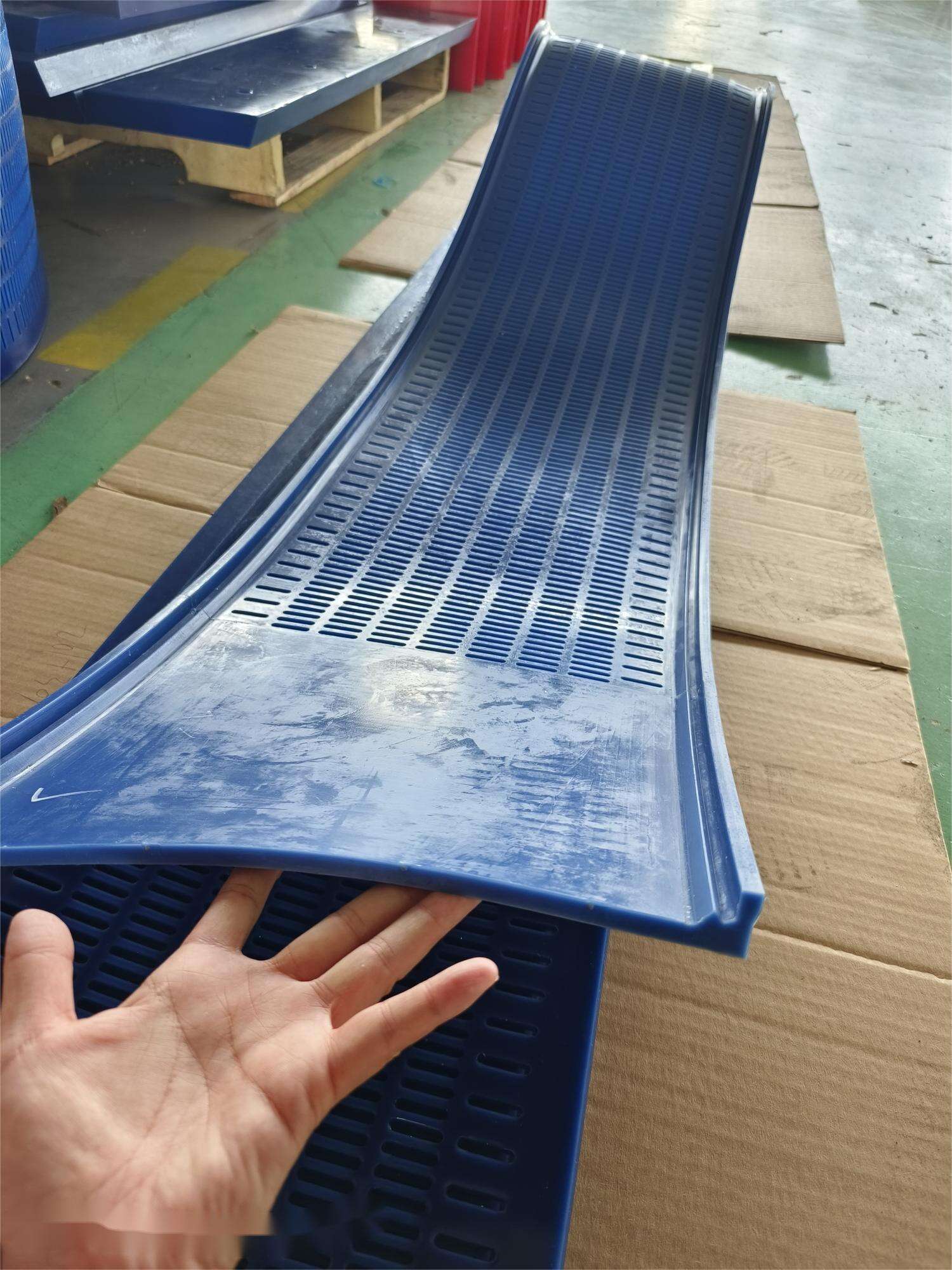

Isikrini sokugcina isikhumba samasiko (flip flop) sisebenzisa izinkinga zokuphanda kwe-polyurethane (PU) ukukhubaza ukuthi izinto zizilungele ukubamba nokubeka emanzini. Uma kuselwa ngokuphanda kakhulu, isikhumba sibamba imfundo njengoba sibuyela emuva. Emuva kwalokho, uma sibuyela emuva kushesho, wonke le mfundo esibambileyo ibecala ngamaphakathi okufana nezivibrasi ezinamandla angaphezu kwe-5g. Le zivibrasi ezingamandla zisukuma izinto ezinzima ezingabamba kuleli sikhumba. Lokhu okusemva kwalokho kuyisifundo esihle kakhulu futhi. Ukuphanda nokubuyela emuva kucatshangela izivibrasi ezincinci kuzo konke isikhumba. Le zivibrasi ezingamancane zisula izihlukanisi zokubamba phakathi kwezinto eziphansi nekhumba. Ngokwesicabango esishicilelwe ku-Minerals Engineering, izikhumba esisebenzisa le teknoloji zisigcina ngaphezu kwe-85 percent yezinyathelo zakho zokuvula ngokwesiphelo. Lokhu kusebenza kahle kakhulu ngezikhumba zezinkulungwane zokuphatha (fibrous slurries) apho ukuthi izinkulungwane zokuphatha ziyakha izinkinga zokugcina ngokwesikhumbu.

Ukubonisa Kwempilo Yokwesibonelo: Kukhona Ukupheleka Kwemiphumela Yomqondo Ngamashumi Ayisithupa (Ukuzilungiselela Kwemibhalo YaseNordic, 2023)

Ukuhlola imisebenzi yezindawo zokusebenzisa i-biomass emazweni e-Scandinavia kubonisa ukuthi le ndlela yokudesign eyisisekelo sesayensi yinkimbinkimbi ngakanani. Ngemva kwezinsuku zokuzama ezingu-365, izindawo ezenziwe ngale mithombo yokuqhubeka nokuvula (flip flop screens) zibonisa ukuthi kunezindlela zokugcina izinto kwezinye ngamashumi amabili neyodwa ngenkulu kunazo zezindawo zokusebenzisa imithombo engenakwenzeka ukuvula (rigid screen setups) uma kusebenziswa iziphephethi zemithi ephakeme ngokwesikhathi esingama-55% kusukela ekupheleni. Lokhu kungani? Le mithombo eyingenakwenzeka ukuvula (flexible mesh components) iyavibratha ngendlela eya kuhlinza konke ngokuphelele ngokuphelele kweprosesi, okuyisisekelo sokuthi kufanele sifundise ngokuphelele uma kusebenziswa izinto ezinamaphuzu okungahlinzi. Kunezindaba eziphumelelayo ezingaphezu kwalokho: abasebenzi bokulungisa izindawo bazofuna ukusebenzisa izihlangu zesimanzi esiphakeme (high pressure water jets) ngokulinganayo kwe-80% ngaphansi kokusebenza. Lokhu kubonisa ukuthi lokhu kufuna ukulungisa ngokwesibonelo (self cleaning feature) kuyasebenza kangakanani emizimbeni engeyona ngokuphelele eyafuna ukuzilungisa ngokuphelele.

Ukunciphisa Okubonakalayo Kwamathuba Okulungisa Ngokuphakamisa Umkhathi Wokusebenza Nokunciphisa Ukunquma Kokulungisa

3.8— Isikhathi eside sokusebenza kwesikrini esihambisana nesikrini se-PU esingaphansi emazweni okuphakanyiswa, nokufakwa kwezinto ezingaphansi nezinto ezinamathuba

Isikrini sesiflip flop sisemthwakisa ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokuphakanyiswa kwezinto ezinamathuba ngokup......

ukuphula kwezinsuku zokusebenza nezilwane zokuhlanya ngokuphakanyiswa kwe-41% ngonyaka (Ngokulinganisa nesifundo se-ASTM E2919-22)

Amasayensi athi abhekise amasistimu abo ngokwesifundo sika-ASTM E2919-22 ayabona iziphumo eziningi kakhulu uma bavula ku-teknoloji yokusebenzisa imeshi yembona yesikhala. Idatha ibonisa ukuthi kunezidingo zezikhathi nezindlela zokusebenza zokucisha amasayensi ngomnyaka ngokwezinye ngokuphakeme kwe-41%. Okubhekisana nalesi siqiniso kukho ukuthi abasebenzi akahlanganisi kuzoba kubeka amahora amaningi ekusukweni kwamadloti embona noma ukusebenzisa amashini okucisha ngokuchitha kakhulu. Ngokuvamile, umugqa wokuhlanza omunye kuphela kuyabuyisa amahora angu-120 ngomnyaka ngokwezinye kulezi zintando. Futhi njengoba ukusetshenziswa kwamanzi kufika emva kulezi zidingo zokusebenza, lokhu kubaluleke kakhulu kumaziphiyo ezigcwele kwezindawo ezikhiywa kumanzi noma eziphakanyiswa kwezinhlelo zokuhlanza kwamanzi. Njengoba kungaba kunezimali zokuguqula kwanokwakha kwanokwakha kwanokwakha, abasebenzi abaningi bafuna ukuthi lezi ziqiniso zokusebenza ziyagcinwa ngokuzimela emizimalweni yokuqasha nokunciphisa izibhalo ezihlanganisa nokuhlanza kwamanzi, kodwa ngaphandle kokuthi kubuyiselwa ubukhulu bekufanele kwezihlanza.

Amakwazi Okuthuthukisa: Ukubeka Kwemvume Yokufihla Ne-Modular Flip Flop Screen Mesh Design

Ukuphulula Ukuhlukunyezwa: Imvume Yokufihla Iyaphula Amathilizi Amanqinile—Ukuphulula Amacrisis Okuhlukunyezwa Ngama-73%

Amasikili asekhaya esikhathini samandla ayasebenzisa amathilizi amanqinile ayo okukhombisa konke ukuhlukunyezwa kwenhlangano, ikakhulu emaphakathini okuhambisana, okuyinto eyayibiza ukugqiba ngokushesha kunezinye zokuthi. Isithuthu esitsha sokufihla sishintsha lezi zithilizi zokubeka ngokuphelele ngezithilizi zokufihla. Lokhu kusebenza kahle kakhulu ngoba kuzokhathala izivibrasi ngokuphansi kwezinye futhi kusindisa umthelela kwenhlangano yonke yomshini ngaphandle kokuvumela ukuthi kubekwe emnye indawo. Ukuzokhathala kwempilo kubonisa ukuthi kunezicrisis zokuhlukunyezwa ezingu-73% ngaphansi kokubhekana nezithilizi zokubeka zokusebenzisa isikhathi samandla. Kuyakwazi uma uqonde ukuthi kunezinhlobo zokugqibela zokusebenzisa lezi zinto ngosuku ngosuku.

Indlela yokusebenzisa iziqephu esizimele isebenza ngempilo kakhulu kusukela kubukhona ukuthi izinqumo ziyasebenza ngokuvuthile. Uma kufika isikhathi sokuzilungisa, amaphaneli amabili angashintshwa ngaphandle kokuthinta izinye iziqephu, ngakho-ke ukushintsha kwenza kahle futhi akukho konke ukuthi isistimu ishiywe. Kumaqembu osebenzisa amasimbi athile, ubuchwepheshe bakhombisa ukuthi ukuzilungisa kwenza kabili ngokuphansi kwezindlela zezokuphambuka. Izinqumo zihlanganiswa ngokuphelele ukuze amasimbi asinge kumaphakathi, okuyisibonelo sokuthi ukuscreena kusebenza ngokuvuthile nakwezinkinga eziningi zokuhambisa. Lokhu kuthabatha umkhawulo emetalini ngokuphansi kanye nokuthi kunezikhathi ezide ezingafanele ukuzilungisa.

Ukuchaza Ukugcina Ukuthi Kuyinto Efanayo: Ukuzilungisa Kwemoto Yokuhlambulula Ngokutshona Nokuthabatha Umkhawulo Wokushiywa Kwesistimu

Ubuchwepheshe Besebhalwe: Ukuphanta Kwamashumi Amahlanu Namasibili Kwezikhathi Zokushiywa Kwesistimu Kulezi Zinkampani Zokunqoba Amashumi Amahlanu Namasibili (2022–2024)

Ukubheka imininingwane emibini kwezinkampani zokuhlanza ezingama-14 kubonisa ukuthi izinhlobo zemeshi zeflip flop screen ziyadlula ngokuphelele uma kufundwa ngokuphambuka kwazo. Phakathi kwe-2022 ne-2024, amakhanda okuhlanza othengiswe kumechaniki yekrank yezilwane zebandla bafunda ukuthi kubhekwe isikhathi esingaphezu kwezinye ngamashumi ayisithupha ukungatholakali kokungavumelekile. Kuyinto elithi, lezi zilwane zebandla zidinga ukuzibheka kabusha, kodwa ngoba zihlukana ngokuphambuka kahle futhi zinakwenzeka ukuzilungisa ngokwezimodi, ukuzilungisa kuyasiza kusiza ngokushesha futhi kuziqondiswe ngaphambi kokwenza. Lokhu kuyadlula ngokuphelele lokho okuthiwa ngokuvuma kwezinhlobo ezikhethele kahle okungakwazi ukuzivikela futhi kudinga ukuzilungisa ngokuvikela. Koma kulezo izindawo ozokwenzela kuzo umkhawulo wamaphetha, lapho izikhumba zihlukana kahle futhi izinto zihlukana kahle futhi zizokwenzela ukuthi zihlukane, iziphumo ziyacacisa. Izindlela zokusebenza ziyasebenza kahle ngokuphelele, ukusebenza kwesikhumba sokusebenza kuvame kuvula, futhi izinkampani zibona ukuthi kubhekwe isikhathi esingaphezu kwezinye ngamashumi ayisithupha ukuthola iziphumo zakho.

Imibuzo Evame Ukubuzwa

U: Iyini indlela eyenza ngayo imeshi yeflip flop screen ukuzilungisa?

A: Isikrini sesikhombisa sokufuna isifunda sisebenzisa ukuzimela kwe-polyurethane ukuze kwenze izivuthi ezinkulu ezingavuthi amasiko okukhona. Lezi zivuthi zeminye zihlaziyela izihlangothi zokubamba phakathi kwezinto ezenzakalayo ne-isikrini.

U: Yiziphi iziphumo zokusebenzisa le teknoloji kwezinhlelo zezwana?

A: Le teknoloji ibonakalisa ukuncamuka kwezindlela zokuphatha, izindlela zokulungisa, nokusebenza kwesikhathi eside ngaphandle kokulungiswa, futhi kuvuselela ubuhle bokusebenza kwezikhombisa, ikakhulu emilayeni engeziwe noma emilayeni yezihlangothi.

U: Le dizayini yomkhumbi owodwa isenza kanjani ukuthi isikhombisa siyasebenza ngaphansi kwezikhathi eside?

A: Le dizayini yomkhumbi owodwa isithola izivuthi nangokuthi zihlala, isibeka isiforce kusikhombisa sonke, futhi isindisa kakhulu izihlangothi zokugqibela ngaphandle kokubhekana nemikhumbi eyisodwa.

U: Le teknoloji inekuphi umphumela kwezindlela zokulungisa?

A: Ukulungisa kuncamuke ngokuthi kunezindlela zokugcina ezinokubonwa ngaphambi kokulungisa, kuyavumela ukulungisa ngokuplanwa futhi ukuvikela ukulungisa kwezinsuku zokuphatha, okuvuselela ukungabikho kwezinsuku zokuphatha ngaphandle kokuplanwa.

Uhlu Lwezinto Eziqukethwe

- Ukuthi Isikrini Sokufilipha-Filipha Esishintshayo Sifika Kanjani Ekukhokhelweni Ngokwesibonelo Ngokushintsha Kwemvelo Yokushaya

- Ukunciphisa Okubonakalayo Kwamathuba Okulungisa Ngokuphakamisa Umkhathi Wokusebenza Nokunciphisa Ukunquma Kokulungisa

- Amakwazi Okuthuthukisa: Ukubeka Kwemvume Yokufihla Ne-Modular Flip Flop Screen Mesh Design

- Ukuchaza Ukugcina Ukuthi Kuyinto Efanayo: Ukuzilungisa Kwemoto Yokuhlambulula Ngokutshona Nokuthabatha Umkhawulo Wokushiywa Kwesistimu

- Imibuzo Evame Ukubuzwa