How Flip Flop Screen Mesh Achieves Self-Cleaning Through Elastic Oscillation

The Physics of Blinding Resistance: PU Mesh Elasticity and Kinetic Energy Release

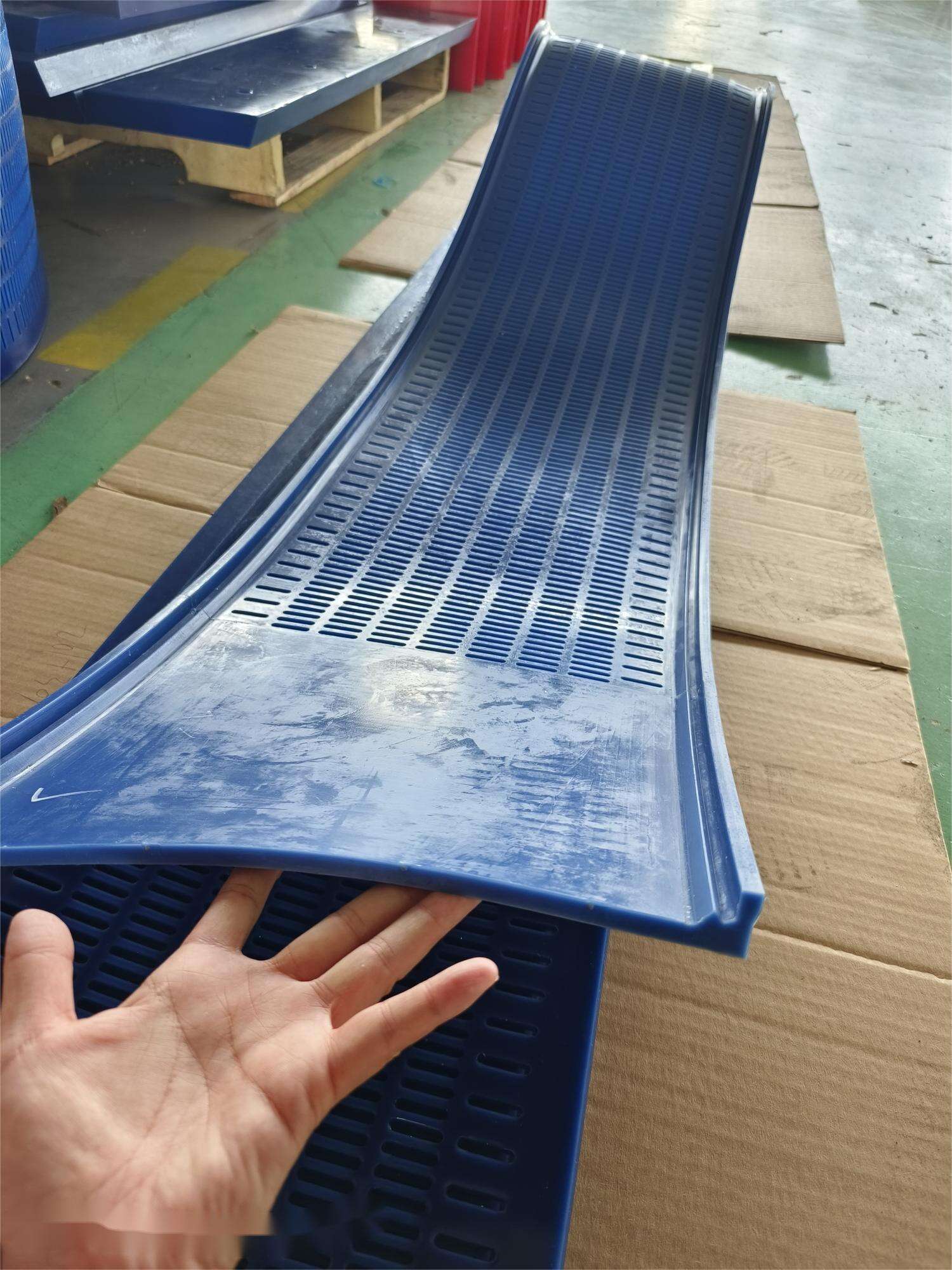

The flip flop screen mesh uses the stretchy properties of polyurethane (PU) to stop materials from sticking and building up on the surface. When stretched tight, the mesh actually stores energy as it contracts. Then when it snaps back quickly, all that stored energy turns into vibrations that hit over 5g of force. These strong vibrations shake loose any particles that might be stuck there. What happens next is pretty clever too. The constant stretching and contracting creates tiny vibrations across the whole screen surface. These micro-vibrations break the sticky bonds between wet materials and the mesh itself. According to testing published in Minerals Engineering, screens using this technology maintain more than 85 percent of their original opening area throughout operations. This works especially well with fibrous slurries where capillary action would normally cause problems with clogging.

Real-World Validation: 62% Fewer Blinding Incidents in Biomass Processing (Nordic Field Trial, 2023)

Looking at actual operations from biomass plants across Scandinavia shows how effective this physics-based design really is. During testing periods lasting around a year, facilities equipped with these flip flop screens saw about two thirds fewer instances of material sticking together compared to traditional rigid screen setups while handling moist wood chips with roughly 55% humidity content. The reason? Those flexible mesh components actually vibrate in a way that keeps everything properly separated throughout the process, which matters a lot when dealing with fibrous materials that tend to get tangled up. And there's more good news too: maintenance crews needed to use those expensive high pressure water jets almost 80% less frequently during operation. That speaks volumes about how well the self cleaning feature works under tough conditions that would normally require constant attention.

Quantifiable Maintenance Cost Reductions from Extended Service Life and Lower Cleaning Demand

3.8— Longer Screen Lifespan vs. Rigid PU Screens in Wet, Fibrous Applications

The flip flop screen mesh lasts about 3.8 times longer than regular PU screens when dealing with wet, fibrous materials. What makes this possible? The flexible movement stops particles from sticking and prevents the kind of wear and tear that breaks down traditional screens. This matters a lot in tough environments such as mineral processing plants or places where they handle biomass. Traditional screens tend to crack after repeated stress, but these new screens spread out the pressure better, so they last much longer. The result? Companies spend less money replacing broken screens and throw away far fewer old ones. Some estimates suggest disposal costs drop by around 60%, which adds up to real savings over time for operations managers watching their budgets closely.

41% Annual Reduction in Labor and Water Use for Cleaning (Per ASTM E2919-22 Benchmark)

Facilities that have tested their systems according to ASTM E2919-22 standards are seeing some pretty impressive results when they switch to flip flop screen mesh technology. The data shows around a 41% reduction in how much time and resources go into cleaning operations each year. What makes this even better is that workers no longer need to spend hours manually scraping debris off screens or running expensive high pressure washers. On average, one screening line alone saves about 120 man hours every month just on these tasks. And since water consumption goes down right along with those labor savings, this becomes especially valuable for plants located in areas where water is scarce or facing tough environmental regulations regarding wastewater discharge. While there might be some initial setup costs involved, most operators find that these efficiency gains translate directly into lower utility bills and reduced paperwork related to environmental compliance, all while maintaining the same level of screening effectiveness they've come to expect from their equipment.

Engineering Innovations: Floating Bridge Mounting and Modular Flip Flop Screen Mesh Design

Stress Mitigation: Floating Bridge Eliminates Rigid Anchors—Cutting Stress Fractures by 73%

Old school screen meshes typically use those stiff anchor points that really focus all the operational stress, particularly around the pivot areas, which often leads to breakdowns way sooner than expected. The new flip flop design swaps out those fixed mounts for something called floating bridge engineering. This actually works pretty well because it soaks up vibrations as they happen and spreads out the force over the whole mesh surface instead of letting it build up in one spot. Real world testing shows about 73 percent fewer stress cracks forming when compared to traditional rigid frame screens. Makes sense when you think about how much wear and tear these things go through day after day.

The modular approach really boosts system reliability and keeps operations running smoothly. When it comes time for maintenance, individual panels can be removed without affecting neighboring parts, so replacements happen quickly and there's no need for complete system shutdowns. For those working with wet aggregates, experience shows that repairs take about two thirds less time compared to traditional methods. The components fit together with precision that stops materials from slipping through gaps, which maintains screening effectiveness even after repeated bending motions. This means less stress on the metal over time and longer periods between necessary servicing.

Reliability Trade-Off Analysis: Elastic Crank Maintenance vs. Net Downtime Reduction

Field Evidence: 57% Drop in Unscheduled Downtime Across 14 Mining Sites (2022–2024)

Looking at data from around 14 different mining operations shows that flip flop screen mesh systems really stand out when it comes to reliability. Between 2022 and 2024, mines that switched to elastic crank mechanisms saw about half again as much fewer unexpected shutdowns. Sure, these elastic parts need checking every so often, but because they wear down predictably and can be fixed module by module, maintenance stays quick and planned out ahead of time. This is totally different from what happens with rigid systems that break down suddenly and need emergency fixes. For places dealing with lots of moisture where screens get blinded and materials fatigue quickly leading to failures, the benefits are clear. Operations keep running smoothly longer, overall equipment effectiveness goes up, and companies see better returns on their investment money.

FAQ

Q: How does the flip flop screen mesh achieve self-cleaning?

A: The flip flop screen mesh utilizes the elasticity of polyurethane to create strong vibrations that shake loose any stuck particles. These micro-vibrations break the sticky bonds between wet materials and the mesh.

Q: What are the real-world benefits observed with this technology?

A: The technology has shown a reduction in blinding incidents, maintenance costs, and labor while increasing the lifespan and reliability of screens, especially in harsh and fibrous environments.

Q: How does the floating bridge design improve screen longevity?

A: The floating bridge design absorbs vibrations as they occur, distributing the force across the entire mesh surface, significantly reducing stress fractures compared to rigid frame screens.

Q: What impact does this technology have on maintenance efficiency?

A: Maintenance is reduced due to predictable wear patterns, allowing for planned checks and avoiding emergency repairs, leading to less unscheduled downtime.

Table of Contents

- How Flip Flop Screen Mesh Achieves Self-Cleaning Through Elastic Oscillation

- Quantifiable Maintenance Cost Reductions from Extended Service Life and Lower Cleaning Demand

- Engineering Innovations: Floating Bridge Mounting and Modular Flip Flop Screen Mesh Design

- Reliability Trade-Off Analysis: Elastic Crank Maintenance vs. Net Downtime Reduction

- FAQ