・Its use is also recommended when the screening surface is enough for the production needed.

・Long - lasting, use in dry and wet screening.

・Easy to install.

・Minimum obstruction due to the conicity and flexibility of its apertures.

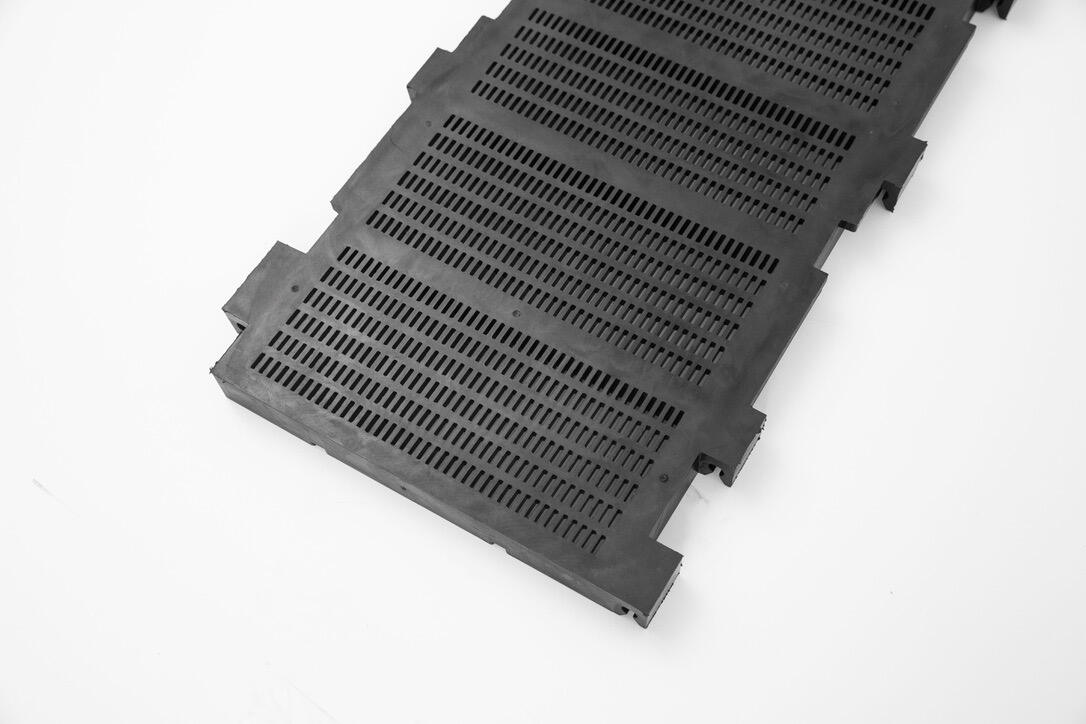

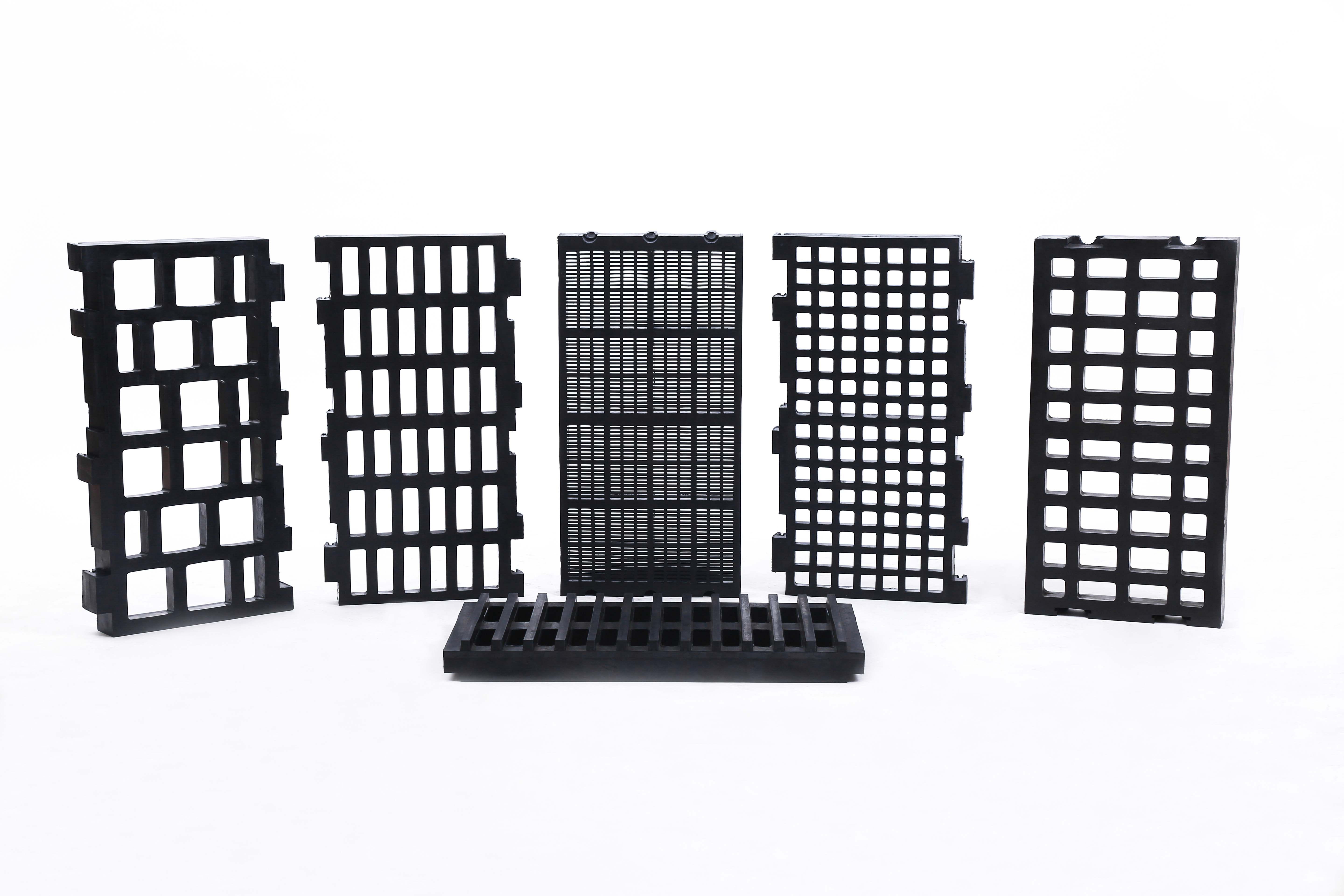

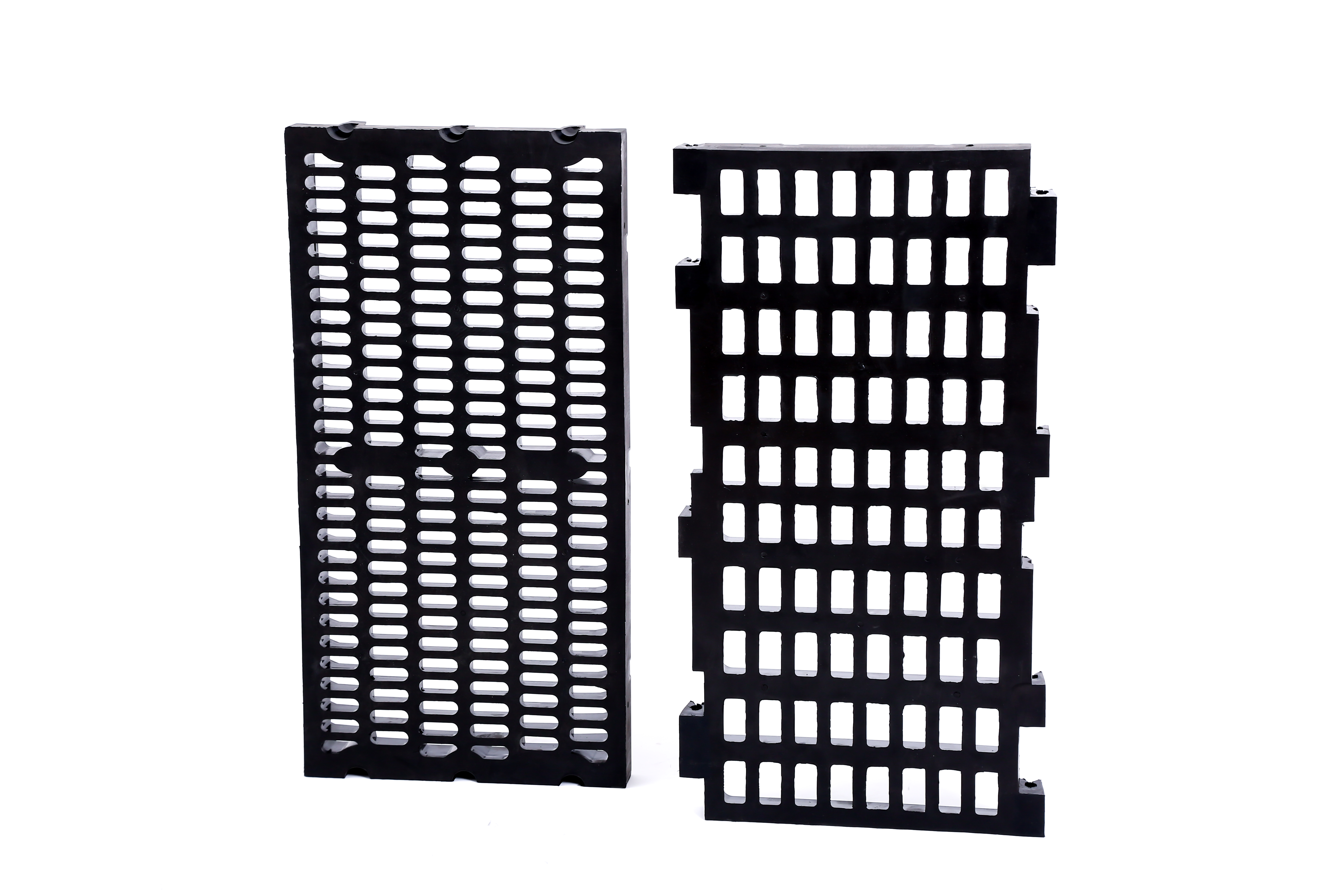

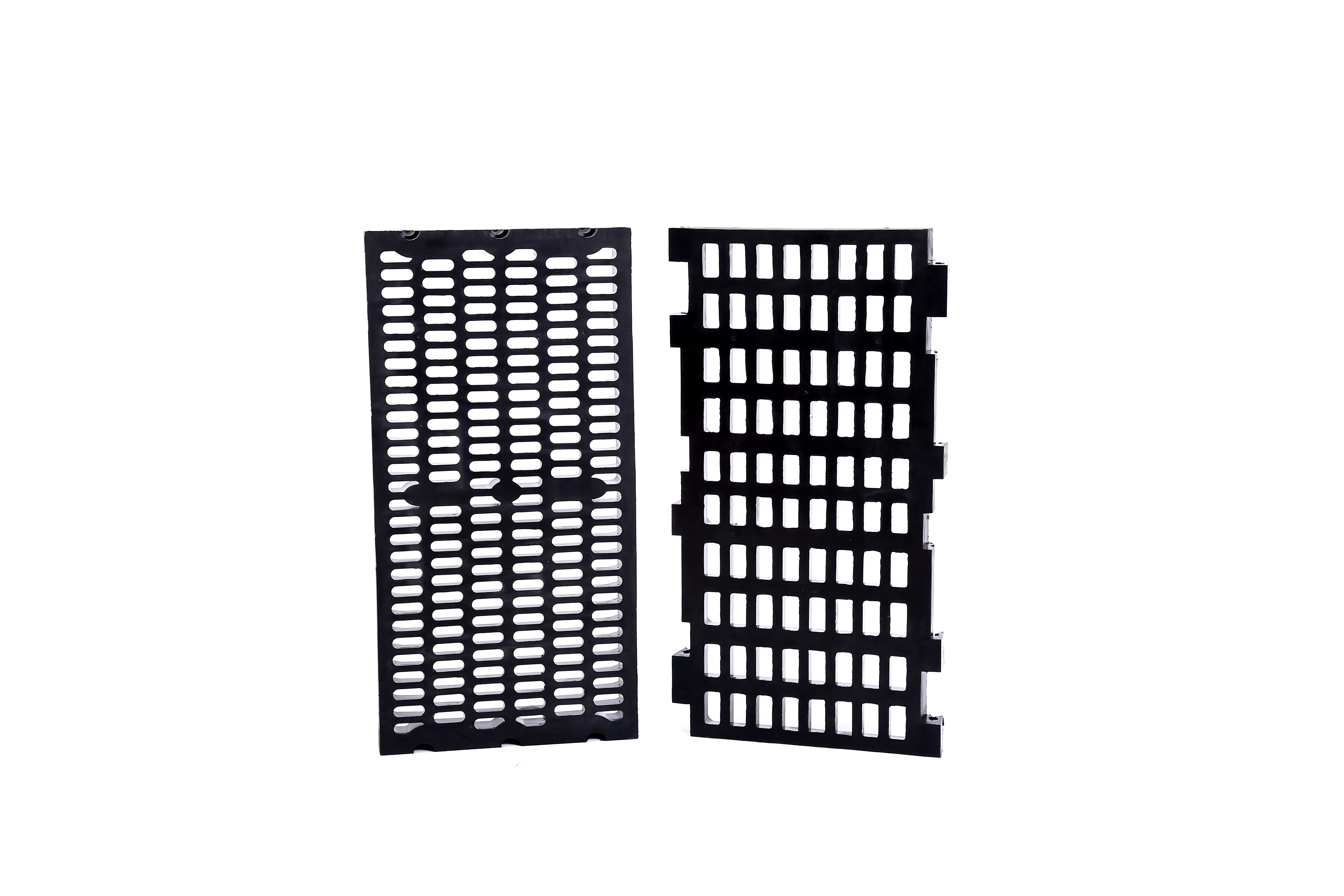

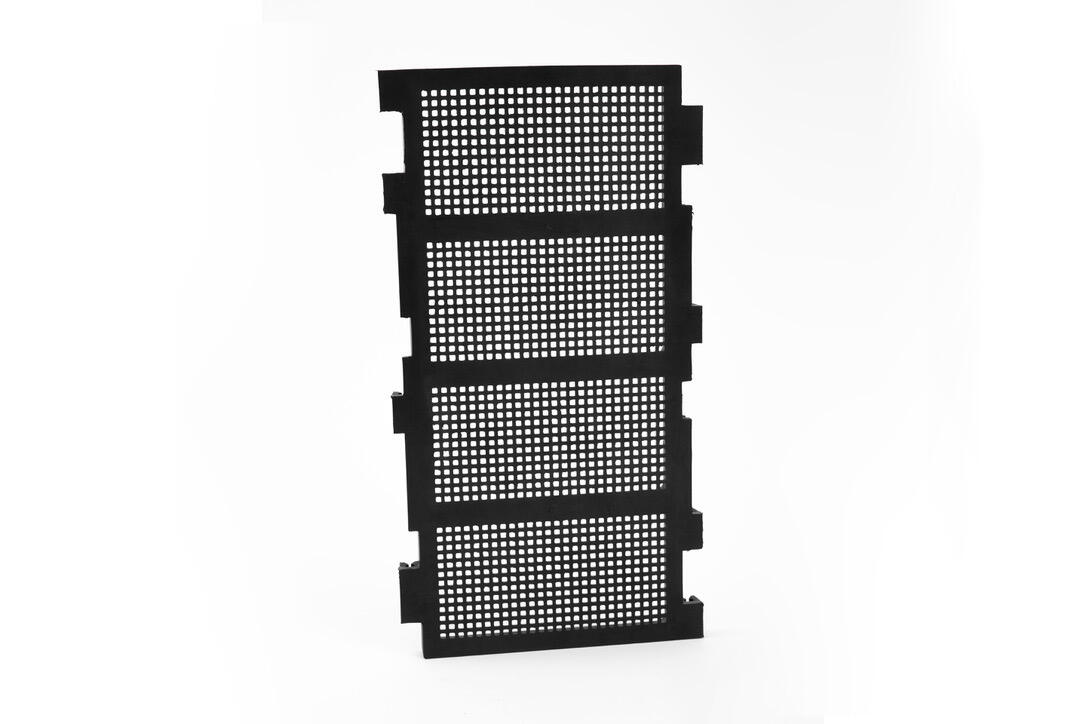

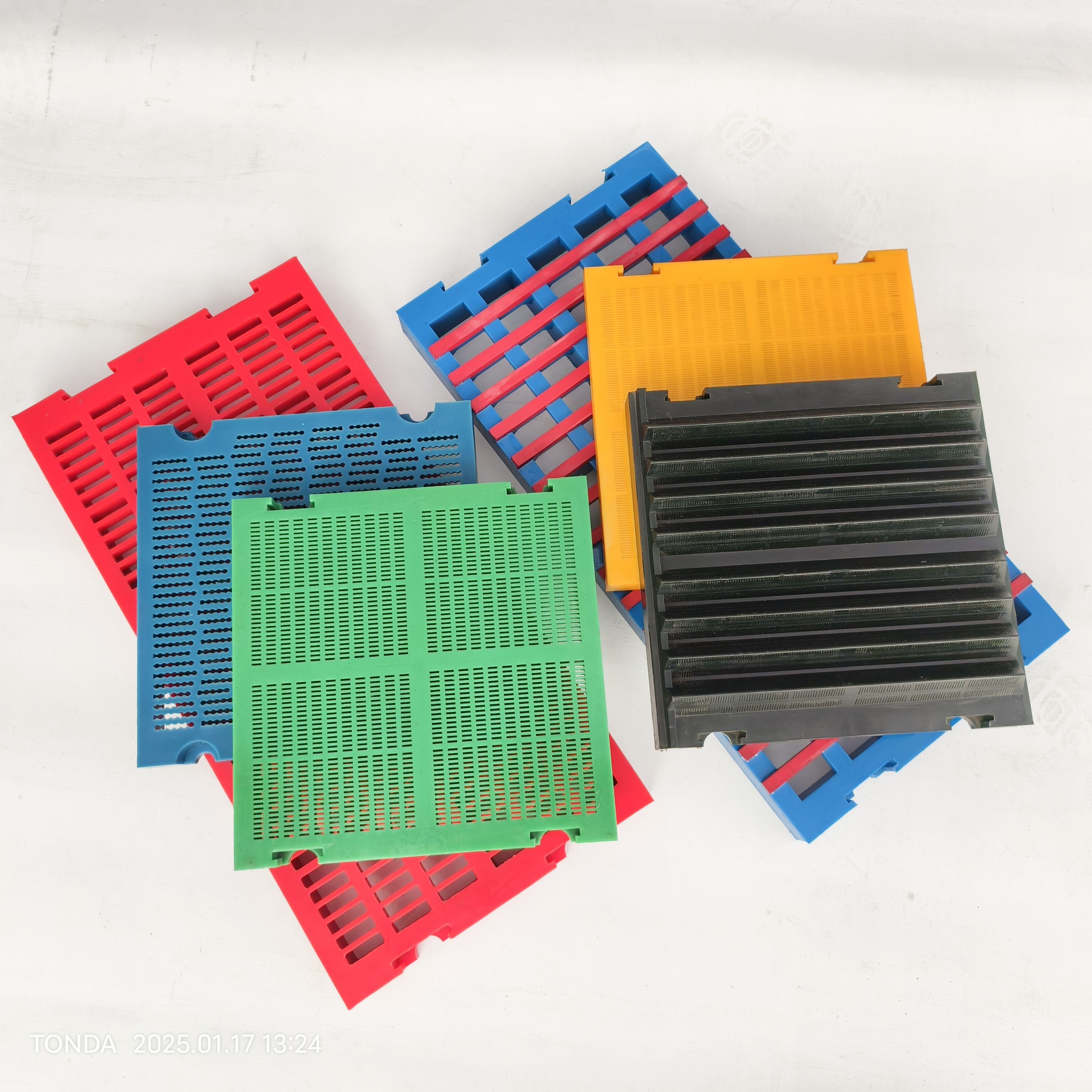

RUBBER MODULAR SYSTEM

Rubber Modular System Flat screen panel with metallic reinforcement

Manufactured under the following standards:

Workface:

・Hardness (°Shore):>65(ISO 868)

・Density (g/cm³):1.20 ± 0.02(ISO 2781 / UNE 53528)

・Tensile strength (Kg/cm²):>125(ISO 37 / UNE 53510)

・ Elongation break (%):>300(ISO 37 / UNE 53510)

・Abrasion resistance (%):<180(ISO 4649 / UNE 53527)

・Tear strength (Kg/cm):>35(ISO 34 - 1)

・Adherence rubber/steel (kg/cm²):80

Support face:

・Hardness (°Shore):85 ± 5(ISO 868)

・Density (g/cm³):1.22 ± 0.02(ISO 2781 / UNE 53528)

・Tensile strength (Kg/cm²):>150(ISO 37 / UNE 53510)

・Elongation break (%):>200(ISO 37 / UNE 53510)

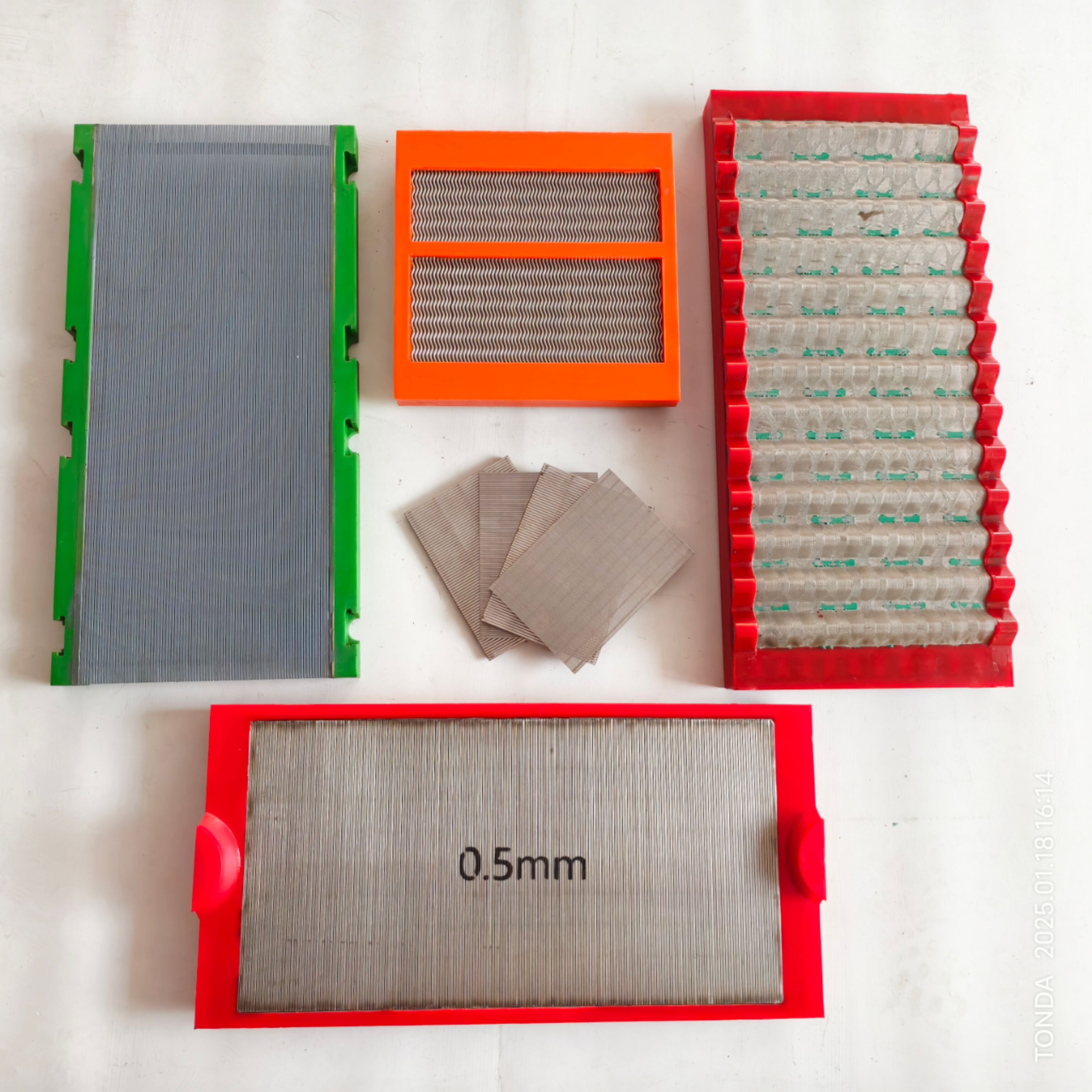

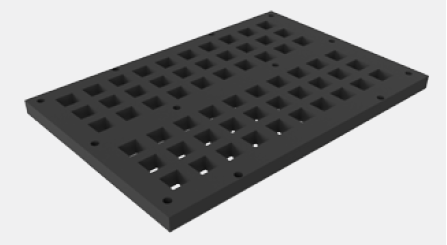

Rubber panel on flat bar frame reinforcement

Hot - vulcanised rubber on welded flat bar frame. 15 - 100mm. Thickness (Fig. A).

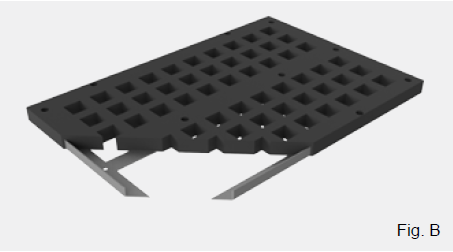

Rubber panel on L profile frame reinforcement

Hot - vulcanised rubber on welded L profile steel frame. 30 - 100mm. Thickness (Fig. B).

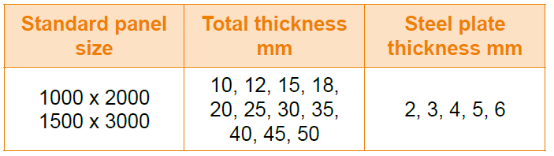

Rubber panel on perforated steel plate reinforcement

Hot - vulcanised rubber on perforated steel plate reinforcement. 20 - 100mm. Thickness (Fig. C).

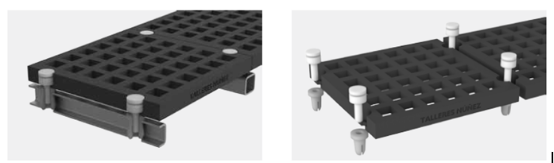

Rubber Modular System Pin and Sleeve

Characteristics :

In this system you secure the panels with a pin, which bends the sleeves on the panel and fixes the panel to the deck. There are many different variations on this system like flat panels with sleeve accessories. Made according to the same quality standards as the rubber flat screen panel.

Core Performance of Rubber Screen Mesh