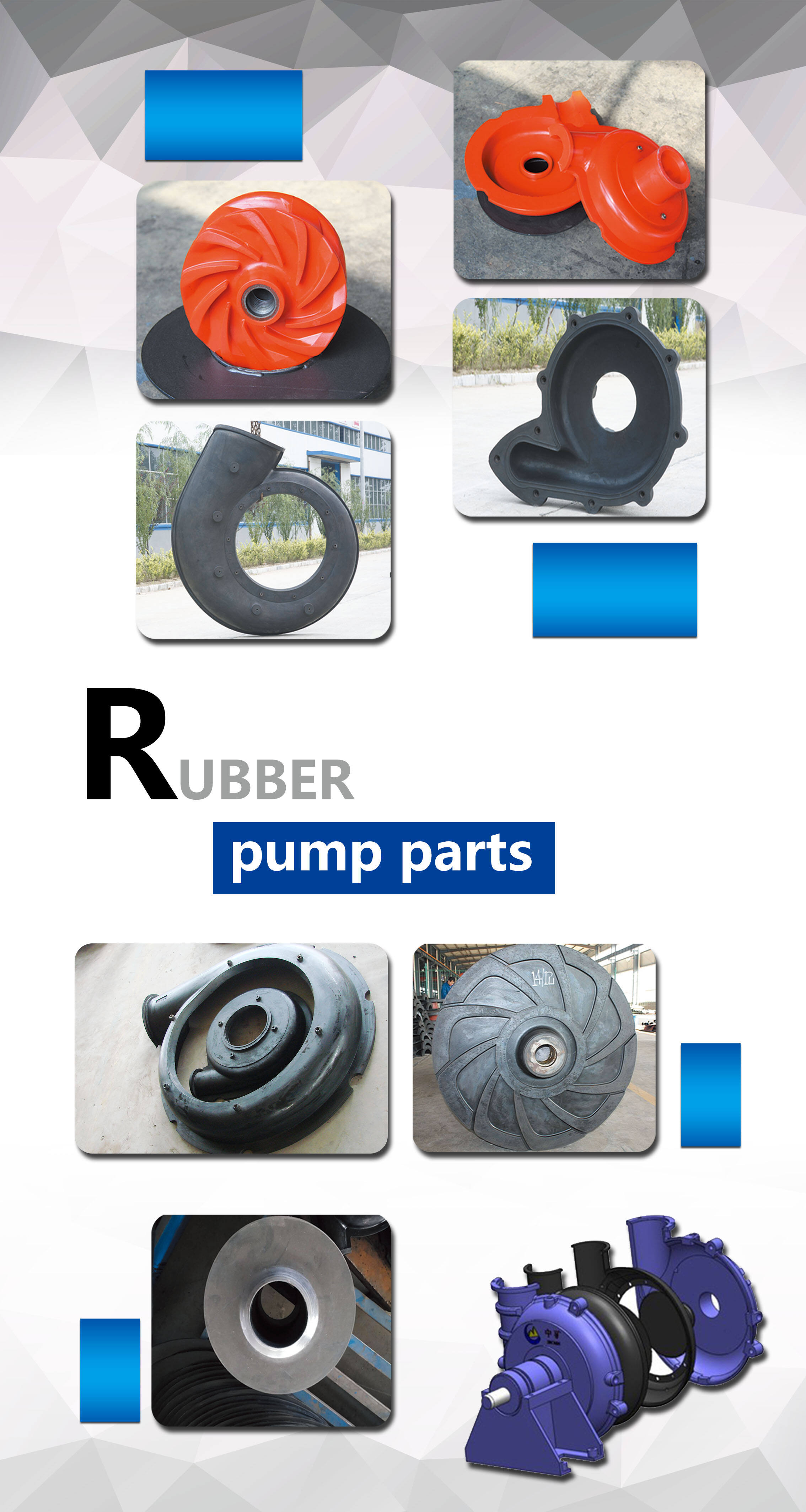

Rubber-lined polyurethane flow-through parts and rubber-lined pump casings are products developed through extensive research and have national patents. The desulfurization rubber pump sleeve is currently the largest sleeve in China. Leveraging a 4500 kN large-scale pressure vulcanizing machine, advanced formulation design, sophisticated vulcanization production processes, and cutting-edge testing instruments, the company ensures stable and reliable product quality. Rubber-lined pump casings can be customized for various pump series, while metal casings are reusable. PNJ rubber-lined sand pump components are primarily used in metal and non-metal mining operations as core parts for transporting sand containing suspended solid particles. They offer excellent wear resistance, tear resistance, and reliable stability. Operating conditions: solid content not exceeding 65%. The slurry pumps, along with their complementary products—rubber-lined pump casings and rubber flow components—constitute our company's flagship offerings. Primarily serving industries such as power generation, metallurgy, coal mining, building materials, and chemicals, these products are designed for handling corrosive slurries containing solid particles. Applications include processing concentrates and tailings, ash removal, coal slurry transportation in coal preparation plants, heavy-medium coal separation, and sand slurry conveyance in coastal and river dredging operations.

Product Features :

(1) Customization: Patented rubber-lined pump casing, tailor-made for specific applications; metal pump casing is reusable.

(2) Wear Resistance: Extended service life; wear value test results range from 0.02 to 0.10 cm³/1.61 km; outperforms alloy linings by 0.3 to 2 times or more.

(3) Corrosion Resistance: Resists corrosion from various acids, alkalis, salts, and seawater. Rubber-lined pumps feature synthetic rubber linings in flow-through sections, suitable for handling 0.5–14% suspended solids, temperatures below 80°C, concentrations below 70% sulfuric acid, below 30% salt/alkali, below 30% sodium hydroxide, and various other inorganic acids. Equipped with high-temperature resistant rubber linings capable of withstanding temperatures up to 150°C to meet user requirements.

(4) Interchangeability: Collaborates with renowned domestic and international pump manufacturers on complementary technical products. Features quick and convenient connection methods.

Product Process Flow Quality Assurance:

Metal Surface Treatment: Sandblasting (post-treatment meets GB/T8923 “Rust Grades and Blasting Grades for Steel Surfaces Before Painting” SA2.5 anchor pattern specifications); Adhesive Application (using a proprietary adhesive formulated by the company to meet national standard requirements); Vulcanization to achieve optimal chemical and physical properties; Final Hardness and EDM Inspection (compliant with national standards, ensuring reliable quality).

TKTL series rubber / PU desulphurizing pump series

The TKTL series desulfurization pumps are single-stage, single-suction horizontal centrifugal pumps independently developed by our company. Primarily used for circulating slurry in flue gas desulfurization absorption towers at thermal power plants, they offer advantages such as safe and reliable operation, easy maintenance, long service life, and low operating costs. This series meets market demands, with product offerings covering all market segments. The TKTL series desulfurization pumps represent a new generation of highly efficient, single-stage, single-suction horizontal centrifugal pumps developed by our company. Incorporating advanced international technology and tailored to the specific requirements of China's desulfurization industry, they are suitable for flue gas desulfurization applications including: Our desulfurization pumps feature extended service life, secure and reliable sealing, user-friendly operation, rational design, and low noise levels. Specially treated for coastal seawater desulfurization and environments with smoke or electrochemical corrosion, they can be customized with molded wear-resistant and corrosion-resistant rubber linings or metal casings for specific operating conditions.

Main pump model:1.5/1B-AT, 2/1.5B-AT,3/2C-AT,4/3D-AT,6/4D-AT,8/6E-AT,10/8E-T,10/8ST-AT,12/10ST-AT,14/12ST-AT,16/14TU-AT,20/18TU-AT,300S-T,350S-T,450ST-T,700TLT,800TLT

| Pump Model | Part | Part Number | Finished Product Weight |

| 1.5/1B-AH | Impeller | B1127 | 1.1 |

| Impeller | B1052 | 1.3 | |

| Front Bushing | B1017 | 1.9 | |

| Rear Bushing | B1036 | 1.8 | |

| Mechanical Seal Rear Bushing | B1036MS1 | - | |

| 2/1.5B-AH | Impeller | B15127 | 2.2 |

| Front Bushing | B15017 | 2.3 | |

| Rear Bushing | B15036 | 2.2 | |

| Mechanical Seal Rear Bushing | B15036MS1 | - | |

| 3/2C-AH | Open Impeller | C2127 | 4.8 |

| Closed Impeller | C2047 | 4.4 | |

| Front Bushing | C2017 | 4.1 | |

| Rear Bushing | C2036 | 3.9 | |

| Mechanical Seal Rear Bushing | C2036MS1 | 3.4 | |

| 4/3D-AH | Impeller | D3147 | 9.4 |

| Front Bushing | D3017 | 8.1 | |

| Rear Bushing | D3036 | 6.8 | |

| Mechanical Seal Rear Bushing | D3036MS1 | - | |

| 6/4D-AH | Impeller | E4147 | 23 |

| Front Bushing | E4018 | 9.5 | |

| Rear Bushing | E4036 | 19 | |

| Mechanical Seal Rear Bushing | E4036MS1 | - | |

| Front Guard Plate | E4083 | 19 | |

| Thickened Front Bushing | E4018TL1 | - | |

| Thickened Rear Bushing | E4036TL1 | - | |

| 8/6E-AH | Impeller | F6147 | 66 |

| Front Bushing | F6018 | 24 | |

| Rear Bushing | F6036 | 39 | |

| Mechanical Seal Rear Bushing | F6036MS1 | 36 | |

| Front Guard Plate | F6083 | - | |

| Thickened Front Bushing | F6018TL1 | - | |

| Thickened Rear Bushing | F6036TL1 | - | |

| 10/8E-M | Impeller | F8147R | - |

| Front Bushing | F8018 | - | |

| Rear Bushing | F8036 | - | |

| Front Guard Plate | F8083 | - | |

| 10/8ST-AH | Impeller | G/FAM 8147 | - |

| Front Bushing | G8018 | 34 | |

| Rear Bushing | G8036 | 68 | |

| Front Guard Plate | G8083 | 74 | |

| Thickened Front Bushing | G8018SRTL1 | 46 | |

| Thickened Rear Bushing | G8036TL1HS1 | - | |

| 12/10ST-AH | Impeller | G/FAM 10147 | 224 |

| Front Bushing | G10018 | 58 | |

| Rear Bushing | G10036 | 96 | |

| Front Guard Plate | G10083 | - | |

| Thickened Front Bushing | G10018TL1 | - | |

| Thickened Rear Bushing | G10036TL1 | - | |

| 14/12ST-AH | Impeller | G/FAM 12147 | - |

| Front Bushing | G12018 | 66 | |

| Rear Bushing | G12043 | - | |

| Thickened Front Bushing | G12018TL1 | - | |

| Thickened Rear Bushing | G12043TL1 | - | |

| Front Guard Plate | G12083 | - | |

| Rear Guard Plate | G12041 | - | |

| 16/14TU-AH | Impeller | GAM14147 | - |

| Front Bushing | H14018 | - | |

| Rear Bushing | H14043 | - | |

| Front Guard Plate | H14083 | - | |

| Rear Guard Plate | H14041 | - | |

| 20/18TU-AH | Front Bushing | U18018 | 290 |

| Rear Bushing | U18043 | 274 | |

| Front Guard Plate | U18083 | - | |

| Rear Guard Plate | U18041 | - | |

| 300S-L | Impeller | RSL/SL 30147 | 128 |

| Front Bushing (6*90掳) | SL30018 | 34 | |

| Front Bushing (6*30掳) | SL30018 | 34 | |

| Rear Bushing (8*90掳) | SL30036 | 54 | |

| Rear Bushing (4*45掳) | SL30036 | 54 | |

| Mechanical Seal Rear Bushing | SL30036MS1 | - | |

| Front Guard Plate | SL30083 | - | |

| 350S-L | Impeller | S35047 | 174 |

| Front Guard Plate | S35083 | - | |

| Rear Guard Plate | S35041 | - | |

| 400ST-L | Impeller | STL40147 | - |

| Front Bushing | TL40018 | - | |

| Rear Bushing | TL40043 | - | |

| Front Guard Plate | TL40083 | - | |

| Rear Guard Plate | TL40041 | - | |

| Mechanical Seal Rear Guard Plate | TL40041MS1 | - | |

| 450ST-L | Impeller | STL45147 | 266 |

| Front Bushing | TL45018 | - | |

| Rear Bushing | TL45043 | - | |

| Front Guard Plate | TL45083 | - | |

| Rear Guard Plate | TL45041 | - | |

| 600TLR | Front Bushing | 600TLR-020 | 114 |

| Rear Bushing | 600TLR-030 | 114 | |

| Rear Guard Plate | 600TLR-050 | - | |

| 700TLR | Front Bushing | 700TLR-020 | - |

| Rear Bushing | 700TLR-030 | - | |

| Rear Guard Plate | 700TLR-050 | - | |

| 800TLR | Front Bushing | 800TLR-020 | 232 |

| Rear Bushing | 800TLR-030 | - | |

| Rear Guard Plate | 800TLR-050 | - | |

| 600GSL | Front Bushing | GSL60018 | 98 |

| Rear Bushing | GSL60043 | 98 | |

| Rear Guard Plate | GSL60041 | - | |

| 700GSL | Rear Guard Plate | GSL70041 | - |

| 800GSL | Front Bushing | GSL80018 | - |

| Rear Bushing | GSL80043 | - | |

| Rear Guard Plate | GSL80041 | - |