How Vibration Frequency Affects Screening Efficiency in Polyurethane Vibrating Screens

Material Stratification and Particle Separation at Different Frequencies

The frequency at which these vibrating screens operate makes all the difference when it comes to how materials separate out. Around 15 to 18 Hz is where things work best for most operations. That sweet spot lets bigger chunks move upward while smaller particles drop down through the screen openings, creating good layers of material. But push past 22 Hz and problems start showing up. According to Mineral Processing Journal from last year, separation gets about 18% worse because the whole system shakes too much, getting mid-sized particles stuck between layers instead of letting them fall through properly. What saves the day though is the nature of polyurethane itself. Its flexible properties keep stratification working pretty well even when frequencies vary between 12 and 20 Hz, maintaining around 92 to 95% efficiency thanks to how the surface rebounds during operation.

Resonance Principles and Optimal Frequency Ranges for Polyurethane Screens

The damping properties of polyurethane create what many call a sweet spot for resonance somewhere around 15 to 22 Hz, which really boosts productivity levels. When operating below 15 Hz there just isn't enough energy to get those sticky materials moving properly through the system. On the flip side, going above 22 Hz starts causing problems too fast at the panel connections where wear becomes noticeable. Some field testing done at actual limestone quarries found that running things at 18 Hz gave about a 22% improvement in throughput over traditional static screening methods. What makes this work so well is how polyurethane actually absorbs those annoying harmonic distortions that tend to mess up metal screens all the time in these kinds of operations.

Real-World Performance: Efficiency Gains at 15–22 Hz in Quarry Applications

When working with granite, running polyurethane vibrating screens between 17 and 19 Hz can slash the amount of material that needs to be reprocessed by around 30%. These screens manage to separate 5 to 20 mm aggregate particles with almost perfect accuracy at 98%, plus they help prevent screen blinding issues that plague many operations. A real world example comes from a quarry in Brazil where operators changed their setup from a fixed 25 Hz system to one that could adjust between 16 and 20 Hz. This simple change resulted in 14% less energy consumption according to the Global Aggregates Report 2024, and importantly didn't affect the production rate which stayed steady at 350 tons per hour. This shows just how much difference maintaining the right frequency range can make for both efficiency and cost savings in stone processing operations.

Adopting Variable-Frequency Drives for Real-Time Optimization

VFDs can make real time adjustments around set points, typically within plus or minus 3 Hz, which really helps systems adapt better to changing conditions. Take a zinc mine operation in Peru for instance they saw their recovery rates jump between 12 and 18 percent when they changed frequencies from 21 Hz during initial screening down to 15 Hz specifically for removing scalps as the quality of the ore fluctuated throughout operations. The ability to fine tune these settings actually reduces the wear and tear caused by running at maximum frequency all the time something that according to Mining Equipment Quarterly last year accounts for about 43 percent of early panel failures. So not only does this approach work better technically, it also means equipment lasts longer before needing replacement or major repairs.

Polyurethane Screen Media Durability and Response Under Varying Vibration Frequencies

Effect of High-Frequency Vibration on Wear Rate and Service Life

When running polyurethane vibrating screens above 22 Hz, wear happens much faster because of all that extra molecular friction between parts. Research published in Tribology International back in 2023 showed something pretty significant too. Equipment operated at 30 Hz instead of just 18 Hz lasted about six months less overall. And when it comes to actual wear rates, we're talking over 2.8 micrometers per hour when these screens are pushed into those really high frequency ranges. What's actually happening down at the material level? The polymer chains start getting out of alignment, tiny cracks form, and everything basically breaks down quicker under this constant pounding from high cycle loads. Makes sense why maintenance teams get so concerned about pushing equipment beyond certain operational limits.

Elastic Behavior of Polyurethane Under Cyclic Loading

When tested between 15 to 20 Hz frequencies, polyurethane shows really good elastic recovery properties, bouncing back about 92% of the energy it absorbs. That's way better than what happens at higher frequencies where only around 67% gets returned. The lower hysteresis means this material keeps most of its strength even after being stressed repeatedly. According to some recent research published in the Journal of Elastomers last year, samples maintained approximately 85% of their original tensile strength after going through an astonishing 1.2 million load cycles. For anyone working in mining operations, these numbers matter a lot since screening equipment often faces between 600 and 800 impacts every single minute in those tough conditions.

Field Evidence: 30% Longer Lifespan at 18 Hz Compared to 25 Hz

Tests conducted over 14 months at a local quarry showed some interesting results. Panels operating at 18 Hz kept their thickness pretty consistent across the board, maintaining around 89% uniformity. That's quite a jump from the 61% we saw when they ran at 25 Hz instead. These differences actually made a real impact on operations. The panels lasted about 30% longer before needing replacement, and maintenance expenses dropped by $18 per ton. Looking deeper into why this happens points to something about polyurethane itself. It works best within certain temperature limits, roughly between -35 degrees Celsius and 60 degrees Celsius. When equipment runs at these moderate frequencies, it seems less likely to suffer those annoying permanent deformations that can wreck productivity down the line.

Key Design Factors That Interact With Vibration Frequency in Polyurethane Vibrating Screens

Balancing Amplitude, Inclination Angle, and Frequency for Peak Efficiency

Getting the best results means getting those three main factors just right: vibration amplitude between 2 to 5 mm, deck angle somewhere around 15 to 25 degrees, and frequency set between 15 and 22 Hz. When dealing with wet or sticky stuff, going for bigger vibrations at slower speeds actually helps things stay on the screen longer. But if we're talking about separating fine particles, then fast vibrations with smaller movements work much better. Most folks working with aggregates find that setting their machine to 20 Hz paired with about 3.5 mm amplitude gives them roughly 92% accurate separation. Plus, this setup tends to keep wear on the screen material down to under 0.08% per hour, which makes sense when looking at long term costs.

Influence of Material Moisture and Particle Size Distribution

The properties of materials being processed play a big role in figuring out the right frequency settings. When dealing with feed material that has more than 7% moisture content, operators usually need to drop down to lower frequencies around 17 to 19 Hz to avoid screen blinding issues. For drier particles in the 0.5 to 5 mm range though, running at approximately 22 Hz tends to work better overall. These modular polyurethane panels we've been using lately really handle varying particle sizes well in practice. Some actual plant tests showed pretty impressive results too - about a 27% increase in throughput when the machine frequency matches up closely with what's happening at the 80th percentile mark of the particle size distribution curve.

Exciter Engineering: Matching Force, Stroke, and Frequency Output

Dual exciter systems capable of producing between 90 and 280 kilonewtons of centrifugal force have been specifically designed to work well with polyurethane materials that typically fall within the 60 to 80 Shore A hardness range. When we look at vibration patterns, there's clear evidence that exciters with a 25 mm stroke running at around 18 hertz can cut down on stress points in screen panels by approximately 41 percent when compared to traditional fixed stroke models. Many newer installations now come equipped with frequency converters which allow operators to tweak settings by plus or minus 3 hertz without losing any torque power. This feature becomes particularly important when dealing with tough materials such as crushed granite or iron ore where maintaining consistent performance is critical.

Advanced Design Strategies for Frequency-Optimized Polyurethane Vibrating Screens

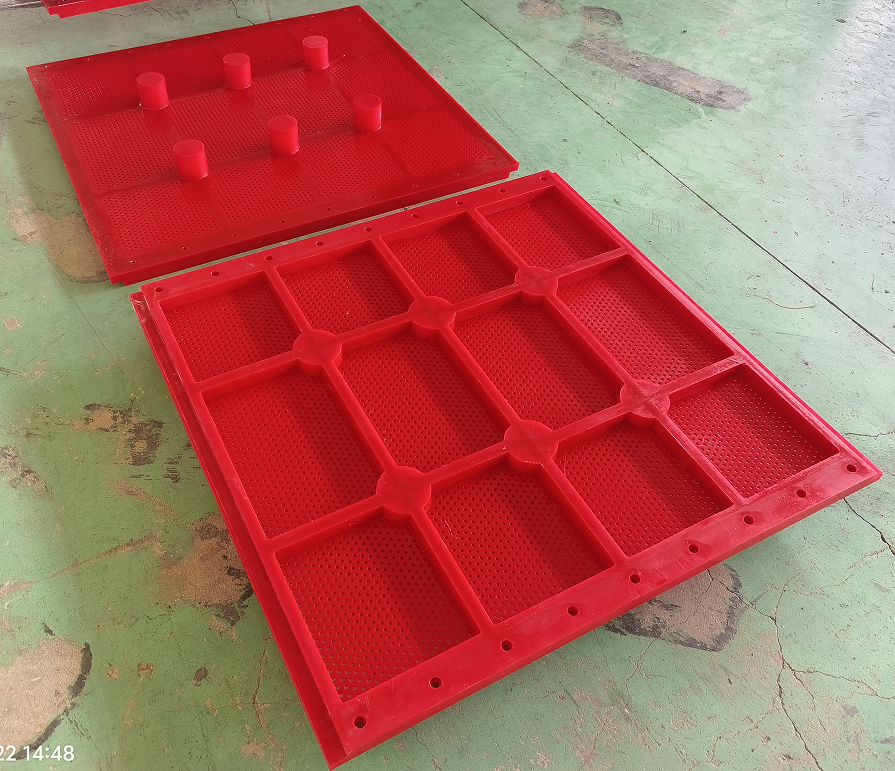

Aligning Mesh Configuration With Operational Vibration Parameters

When screen mesh geometry matches the right vibration parameters, performance gets noticeably better. The aperture sizes matter quite a bit too. They need to account for what kind of separation we're aiming for (usually between half a millimeter and three millimeters) plus how fast things are vibrating (typically around 15 to 25 hertz). Some recent studies have shown something interesting happening at 18 hertz specifically. When screens use wires that are 2 mm thick instead of the usual 1.5 mm ones, they actually separate materials better by about 23 percent according to Vibration Tech Quarterly from last year. This change helps reduce material sticking problems without making the whole system any less durable during those long hours of constant operation.

Using Finite Element Analysis to Simulate and Predict Screen Performance

These days, engineering crews rely on finite element analysis (FEA) when they need to understand how stress spreads through materials at different frequencies. The numbers tell an interesting story too - tests indicate that components exposed to vibrations at 20 Hz experience roughly 40 percent less stress buildup in their connection points compared to those subjected to 28 Hz waves. Looking deeper into this phenomenon, experts run simulations covering over half a million repeating cycles just to get a handle on how long screens will last before failing. What comes out of all these calculations is pretty impressive actually: predictions about equipment life expectancy are accurate within about plus or minus seven percent. And let's face it, knowing what's going to break down next makes a world of difference for companies dealing with minerals where unexpected stoppages cost serious money.

Debunking the Myth: Why Higher Vibration Frequency Doesn't Always Mean Better Throughput

Most people think higher frequencies are better, but actually anything over 22 Hz tends to cut down on throughput by around 12 to maybe even 18 percent because particles just keep bouncing back instead of moving through properly. Aggregate plant operators have noticed something interesting too: when they run their equipment between 17 and 20 Hz, they can handle about 30-something percent more material compared to those running at 25 Hz or higher. Why does this happen? Well, polyurethane has this unique property where it gets stiff too quickly at higher frequencies. That stiffness makes it harder for the material to soak up all those impacts during the screening process, which ultimately slows things down.

Frequently Asked Questions

What is the optimal frequency range for polyurethane vibrating screens?

The optimal frequency range for polyurethane vibrating screens is typically between 15 and 22 Hz. This range allows for effective material stratification and particle separation, while minimizing wear and tear on the screens.

How does vibration frequency affect the durability of polyurethane screens?

Higher vibration frequencies, especially those above 22 Hz, accelerate wear and decrease the service life of polyurethane screens due to increased molecular friction and cracking. By contrast, operating at moderate frequencies between 15 and 20 Hz extends the lifespan of the screens.

What role do variable-frequency drives play in optimizing screen performance?

Variable-frequency drives (VFDs) enable real-time adjustments of vibration frequency, allowing screens to adapt to varying material conditions, enhancing efficiency, and extending equipment longevity by reducing excessive wear from constant maximum frequencies.

Why is mesh configuration important in polyurethane vibrating screens?

Mesh configuration, including geometry and wire thickness, is crucial as it should match the operational vibration parameters to ensure effective material separation and reduce sticking problems, ultimately enhancing screen performance.

Table of Contents

- How Vibration Frequency Affects Screening Efficiency in Polyurethane Vibrating Screens

- Polyurethane Screen Media Durability and Response Under Varying Vibration Frequencies

- Key Design Factors That Interact With Vibration Frequency in Polyurethane Vibrating Screens

- Advanced Design Strategies for Frequency-Optimized Polyurethane Vibrating Screens

- Frequently Asked Questions